- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- technical parts

Results for

Technical parts - Import export

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

Depending on the industrial sector, more or less complex processes take place with more or less difficult media. These media are needed either for the production process itself or for supporting processes and can have very special properties. Thanks to the VERINOX used, Lipp can tailor the tank material exactly to medium and process and thus offer the best technical and economic solution. Parts and accessories can also be individually selected and installed according to the project. This means that Lipp system solutions can be considered both for simple solutions such as part of a fire protection system, but also for complex requirements, such as in the pharmaceutical and beverage industry. So much flexibility in terms of the possibilities for use is a powerful argument for cooperation with Lipp. Engineering offices gain a partner who covers a wide range of applications and provides the same high quality worldwide.

Request for a quote

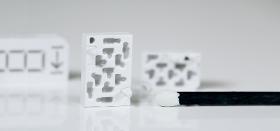

SUPER-FILAMENT EINE MARKE DER ADDITIVE MATERIALS GMBH

Germany

Our advanced manufacturing crafts highly precise, custom-engineered components for technical applications in small series. Precision in 3D Construction and Modeling: Expertise in precise 3D construction and modeling underpins the production of technical production parts in small series. Leveraging advanced 3D printing, we create components meeting high standards of accuracy and functionality. Diverse Material Portfolio for Technical Applications: From classic materials (PLA, PET-G, ASA, ABS) to specialized polymers and fiber composites, our varied material portfolio caters to specific needs of technical production parts. Optimized Manufacturing for Small Series: Our techniques ensure efficient, precise production for small series, balancing cost-effectiveness and quality for swift market entry.

Request for a quote

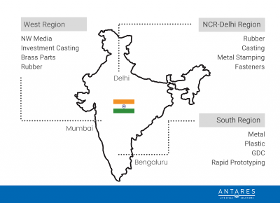

ANTARES LIFE CYCLE SOLUTIONS GMBH

Germany

Components in small volumes, replacement parts which are difficult to source or have even become obsolete, requirements and customer demands that fluctuate substantially (and are therefore effectively unplannable) All these are challenges in the day-to-day life of OEMs and TIER-X manufacturers in off-highway, commercial vehicles, mechanical engineering and many other industries when it comes to delivery performance towards end-customers. Our solution: for every case the most suitable manufacturing technology combined with our own experienced engineering team – everything from a single source. Technologies: Additive Manufacturing / 3D printing Casting Parts (sand casting, pressure casting and many more) CNC Parts Technical Plastics Parts Rubber and Elastomer Parts (gaskets) Assembly of Modules and Systems and many more

Request for a quote

KUNSTSTOFFTECHNIK SCHMID GMBH & CO. KG

Germany

Customers from a wide range of industries rely on technically sophisticated injection-moulded parts made with up to three components. Our unique strength lies in the areas of multi-component technology, thermoplastics processing, elastomers and high-performance plastics.

Request for a quote

STOROPACK HANS REICHENECKER GMBH

Germany

PIOCELAN® MEANS OPTING FOR OUTSTANDING MECHANICAL PROPERTIES. As a material, Piocelan® is an intelligent combination of polystyrene (EPS) and polyethylene (PE) or EPS and polypropylene (PP), bringing together the best of both worlds: Piocelan® features the low density of EPS and the exceptional chemical resistance and shock absorption of PE respectively PP. It’s especially robust and wear-resistant – characteristics that make Piocelan® molded parts the ideal solution for difficult conditions, including high circulation, and other special requirements.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

STOROPACK HANS REICHENECKER GMBH

Germany

EPP CAN WITHSTAND HEAVY STRAIN. Technical molded parts made of expanded polypropylene (EPP) are indispensable in a number of industries – in car manufacturing, for example. Thanks to their outstanding energy-absorbing properties, EPP parts improve passive safety and provide better protection for vehicle occupants. Accordingly, they are used to make fenders, headrests, and other impact absorbers. EPP can absorb even more energy when used in combination with metal. One secondary benefit is the low weight of the innovative material: EPP molded parts thus cut fuel consumption and make cars more eco-friendly. Due to the fact that it can be precisely shaped, EPP also cuts a good figure elsewhere – as a sun visor, paneling, or a toolbox for precisely accommodating breakdown sets. Its extraordinary insulating ability is also the reason why notable manufacturers in the heating and air conditioning industry use EPP molded parts from Storopack for their products.

Request for a quote

STOROPACK HANS REICHENECKER GMBH

Germany

EPS MEANS OPTING FOR MAXIMUM FREEDOM. Technical molded parts made of expanded polystyrene (EPS) are the material of choice when it comes to good moldability, light weight, and outstanding insulation. EPS is ideal for the lost foam casting process. This involves embedding an EPS foam model of the desired component within a casting chamber in molding sand and dissolving it by pouring in molten metal. Compared to other processes, this affords greater design freedom when creating the cast parts, because neither built-in parts nor connections are necessary. As such, even complex cast components can be produced easily and particularly inexpensively. EPS also serves the construction industry well: Due to their very low thermal conductivity, technical molded parts are used as insulation elements and panels for underfloor heating systems. They can also be used as formwork elements. Whether for individual geometries or technically demanding structures, EPS makes it possible.

Request for a quoteResults for

Technical parts - Import exportNumber of results

8 ProductsCompany type