- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- storage-systems

Results for

Storage-systems - Import export

DIENER ELECTRONIC GMBH & CO. KG

Germany

Vacuum degassing / outgassing With the aid of vacuum outgassing, unpleasant tastes or odors can be degassed and thus rendered tasteless. Altitude simulation For aircraft transport, it is essential to perform tests and simulations at a pressure <800 mbar, since in cargo holds, pressure equalization takes place, but cannot compensate for all fluctuations. Vacuum storage systems The safest way to store highly sensitive components is under vacuum. Under the vacuum environment, your components are protected from all external influences. Control and process control Our specially developed control program offers not only the possibility to monitor, but also to program and store various process sequences. High and ultra-high vacuum From the pressure range of rough vacuum to fine vacuum and ultra-high vacuum, we are able to meet your process requirements with our systems.

Request for a quote

KABELMAT WICKELTECHNIK GMBH

Germany

This storage system is mainly used in workshops and production areas. It allows clearly ordered storing and an entangling-free unwinding. Due to lockable rollers, the system can be used mobile or stationary. Note: Only suitable for manual unwinding! Further combinations of storage units available on request!

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

ATMOSPHERIC PRESSURE, MAINTENANCE FREE AND PROTECTED AGAINST EXTERNAL EFFECTS The pressureless gas storage system of Lipp is used for the storage of gas produced on landfill sites, waste water treatment plants and also as external storage on biogas plants. The system is determined by its robust and technical advanced construction where the gas balloon is protected by a galvanized steel tank. This protects the balloon against UV light and also other external factors. The system is mostly utilized at landfill sites or WWTP to buffer the gas before its further processing. The experience gained during the past decades has improved the complete system and the single components and makes it a perfect choice for end users and general contractors.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

Beside the protection against external effects as UV or other external effects which could damage the foil, the unique construction enables a reliable and measureable leak test as well as an accurate filling level measurement at all times. Compared to low pressure systems and double membrane gas accumulators the Lipp system has very low operation and maintenance costs.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

LIPP® Gas Accumulators were developed as a system for the nonpressurised storage of dry gas which has been used for over 300 projects worldwide over the past years or more. Sizes from 30 to 5000 m³ are available according to the gas yield in each case. The gas accumulator consists of two parts a bubbleshaped storage balloon and a steel container to protect the balloon against mechanical damage and the effects of weathering. Speciality Accurate level measure of stored gas. In biological processes, gas production is not continuous. That is why the utilisation of gas (e.g. in a combined heat and power plant) requires an accumulator in order to compensate for fluctuations during gas production and to bridge downtimes for plant repairs and maintenance. Besides high functional and operating safety, other important criteria for the construction and operation of gas tanks include the economic aspects of investment and maintenance costs.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

LIPP welded tanks are erected using the LIPP Welding Technology, a unique method of construction enabled by a custom automated rig designed and manufactured by LIPP. This procedure can claim a number of advantages over other traditional welding methods. Firstly, the unique steel profile increases stability and so reduces material costs at the same time. Secondly, the automated endless tape process continually welds layers below in a rotational cycle and reduces the number of on site workers. LIPP Welding Technology enables welding both black steel and stainless steel of different grades, allowing numerous applications. LIPP aims to increase construction efficiency through the implementation of unique techniques and technology, ultimately benefiting customers via a cost effective system. The key facets for the construction of a LIPP storage system are automation, continuously variable tank dimensions, reduced space requirements for onsite construction and increased worker safety.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

With such flexibility, the sales team at Lipp can enable any customer to specify exactly what is needed for their installation. From complete, turnkey systems to individual components and accessories – Lipp can support customers whatever their requirements. Consultation is a primary objective for Lipp before any work is undertaken. Lipp provides diagnostic tests, efficiency calculators and flow sheets to visualise a tank system and inform the customer of the performance they can expect. This is especially useful for anaerobic digestion – where Lipp experience supports the efficiency and safety of the system from design through to construction. Particular attention is always paid to the content to be stored within the storage system, which allows Lipp to offer customers the chemically stable materials and accessories to get the most from their storage tanks and digesters. Fundamentally, Lipp’s focus on the customer allows consultation and sales to be perfectly integrated

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

TAILOR MADE SOLUTIONS As a family owned company that offers a unique tank storage system to customers across the world, Lipp knows the high value of effective communication and customer support. Whether consulting with a Lipp specialist on a tank system design or ordering extra accessories for an installed system, the same professional help and guidance is always available. Lipp focuses on providing the optimum solution for the user, entirely customisable and ultimately efficient. Lipp will always recommend solutions that will increase the performance of a tank system while also ensuring – that it is the most suitable solution for the customer.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

SYSTEM SOLUTIONS FOR THE STORAGE OF CEREAL PASTE AND SUGAR BEET Lipp plans and sells storage systems for biomass such as cereal paste or sugar beet under the brand names LIGAVATOR and BETAVATOR. These systems are generally gas tight and both roof and container base (optional) are made of solid stainless steel, since the stored media can give rise to very aggressive juices and gases. With this type of storage the substances are preserved and can be used over a very long period. Automatic withdrawal and substrate delivery can also be installed in the following systems by an appropriate control system. APPLICATION EXAMPLES AND REFERENCES In addition to pure crop storage, the Lipp LIGAVATOR / BETAVATOR systems are mainly used as substrate storage for agricultural or industrial biogas plants, and are installed before the fermenter for appropriate substrate supply. They allow largely automated control of a biogas plant, as there is no need for a regular manual substrate supply.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

HIGH QUALITY AND SAFETY STANDARDS LIPP brings over 55 years of experience in the field to every project, helping to meet the most demanding safety and quality standards that will deliver profitability and reliability. Proven technologies, such as the spiral LIPP Double Seam System and Verinox material, have been developed and proven to deliver both flexible and efficient storage systems. Tanks are erected via a construction method exclusively employed and developed by LIPP, delivering customizable tanks for any application with a volume of 10,000m3 or more. Perfectly matched to the purpose of each installation, each tank incorporates large volume with a customized interior. LIPP understands that adaptability provides solutions for various applications and requirements – so customers can even specify their own services to lower the total cost of investment.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

Gas storage systems by Lipp have been successfully installed in more than 300 projects in Germany and worldwide. The gas storage capacity extends from 30 to 5,000 m³. The gas resistant PVC gas holder is protected by a galvanised steel cylinder. The self supporting roof is made of 1.4301 high grade stainless steel. The Lipp gas holder is offered as a complete system, including sensors and built in parts as well as steel construction, and can be easily integrated into an existing system. The main area of application of the Lipp gas holder is municipal waste water treatment plants and landfills which want to balance out fluctuations in gas production and at the same time need a buffer store for possible downtimes. A further gas holder may also be of interest for direct marketing of biogas, where feed in at certain times is necessary. The Lipp gas holder is especially attractive when considering the fact that electricity cannot be stored. But (bio) gas, which is used for power generation

Request for a quote

CPC EUROPA GMBH

Germany

Acceleration test: The acceleration test is based on a slide-crank mechanism with a flywheel as the crank. The crank imparts high acceleration and speed to the block with finite stroke. By adjusting the rotational speed of the motor, the service life of the block can be determined at different accelerations and speeds. — Both downward-bolt and upward-bolt track rails available — High rigidity structure — Reduced lubrication requirements for environmental soundness and maintenance cost saving — Built-in lubricant storage and supply system — Dustproof design Standard seals (S) — Reinforcement plate design (Patented)

Request for a quote

ANDREAS MAIER GMBH & CO. KG (AMF)

Germany

Wireless seonsoring systems from AMF: flexible, compact and economical. They enable fully automated production processes for clamping technology as well as for modern handling and storage systems. The system consists of sensors and transmitter units that are interlinked both with the gateway and recipient, which communicates wirelessly with the machine control by means of Bluetooth Low Energy.

Request for a quote

DAMBACH LAGERSYSTEME GMBH & CO KG

Germany

The DAMBACH material flow system (MFS) enables easy connection of automated storage and retrieval systems as well as conveyor systems to ERP and warehouse management systems (WMS). The software package named MFS-BASIC is distinguished by the variable transport control of storage and retrieval machines, pallet-shuttle-systems, conveyor technology and rail guided vehicle systems. Flexible route strategies enable utilization-dependent regulation of material flows. Whether management of top performance in large floor conveyor systems with switches or optimized buffer space management in conveyor technology systems. The powerful MFS from DAMBACH fulfills many requirements. Depending on the functional scope of the customer's warehouse management system (WMS), DAMBACH offers the option of an expanded material flow system named the MFS-PLUS.

Request for a quote

DAMBACH LAGERSYSTEME GMBH & CO KG

Germany

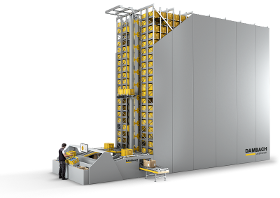

Automated small parts storage for a wide range of applications – whether as picking-, buffer- or distribution storage. A variety of small parts carriers and small containers can be stored efficiently with the LOGI-KIT MINI. The system is thereby as flexible as your requirements. Load weights can vary between a few grams up to 300 kg. With storage heights from 3 to 27 m, it can be integrated easily into many existing buildings. High goods throughput means that the system is perfectly suitable as a "micro-fulfillment" system in the tightest space. Cartons, Euro containers and trays are automatically transported to the picking station. The "goods-to-person" principle leads to the elimination of unproductive order picking way times and time needed for order fulfillment is reduced.

Request for a quote

DAMBACH LAGERSYSTEME GMBH & CO KG

Germany

With LOGI-KIT INFINITY you save expenses regarding manual forklift truck operations and increase your storage capacity. With only a few klicks the configurator calculates the potential of a LOGI-KIT solution based on your warehouse parameters.

Request for a quote

DAMBACH LAGERSYSTEME GMBH & CO KG

Germany

With LOGI-KIT ZERO you save expenses regarding manual forklift truck operations and increase your warehouse performance. With only a few klicks the configurator calculates the potential of a LOGI-KIT solution based on your warehouse parameters. Please enter the required information below.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DAMBACH LAGERSYSTEME GMBH & CO KG

Germany

DAMBACH storage and retrieval machines (SRMs) and materials handling control systems form the basis for greater efficiency in the warehouse. Control systems decide how economically and reliably warehouse systems work. DAMBACH therefore combines expertise and experience with knowledge of this branch of industry and the latest technology. The result is a wide range of solutions covering all the requirements of high bay and small-parts warehouses and the apron. From simple, low-cost controls for storage and retrieval machines or conveyor systems to standard applications for fully automatic SRM operations – and with energy recovery if required. The CARRIER and the COMPACT SHUTTLE of the MULTIFLEX pallet shuttle system as well as the RAIL CART of the Inductive Rail System MONOFLEX are equipped with decentralized controls. This minimizes sources of error and shortens installation times. The transport vehicles monitor and regulate the motion sequences on their own.

Request for a quote

DAMBACH LAGERSYSTEME GMBH & CO KG

Germany

As a supplier of sophisticated and standardized load handling devices, DAMBACH allows you to configurate your ideal product via online shop. With a large selection of telescopic forks such as double-deep, single-deep or single forks, DAMBACH provides solutions for pallets, mash boxes and special load carriers. Furthermore you will find a wide variety of different telescopic tables for small parts storage. In addition, with variable box grabbers and clamping grabbers boxes a secure storage of boxes, cartons and crates can be enabled.

Request for a quote

DAMBACH LAGERSYSTEME GMBH & CO KG

Germany

The DAMBACH COMPACT SHUTTLE for high bay warehouses, makes pallet storage and retrieval even more efficient. Used in conjunction with rail-guided storage and retrieval machines, the COMPACT SHUTTLE enables warehouse operators to achieve really compact, multi-deep pallet storage. To do this, the storage lanes are fitted with rails on which the shuttles can run. Shuttle and storage and retrieval machine (SRM) therefore form one logistical unit: the shuttle runs on the rails to the allotted storage position where it sets down or picks up a pallet, and the SRM transports the shuttle to the correct storage or retrieval point in the warehouse. Communication between the parent vehicle and the COMPACT SHUTTLE is by way of a point-to-point radio link. This link monitors itself permanently to guarantee maximum communication reliability. Especially a combination of transfer cars and COMPACT SHUTTLE can reduce the energy usage, while maintaining a high throughput capacity.

Request for a quote

DAMBACH LAGERSYSTEME GMBH & CO KG

Germany

This rail guided vehicle system MONOFLEX is powered by inductive energy. The smart track guided vehicles run on floor mounted twin rails. The MONOFLEX system sets new standards in terms of throughput, flexibility, and scalability. True to the motto “dynamic warehousing”, this rail guided vehicle system from DAMBACH Lagersysteme provides a high-performance conveying system for the apron in warehouse systems, or functions as an alternative to conveyor systems with continuous conveyors. For example, the MONOFLEX can form the ideal complement to the MULTIFLEX pallet shuttle system. This rail guided vehicle system from DAMBACH consists of high-performance transport carts and a twin rail track. The track is made from anodized aluminum, which is not only robust, but easy to install. Simple switches ensure good availability, even in the case of complex plant layouts. With a 1:1 distribution of the material flow

Request for a quote

DAMBACH LAGERSYSTEME GMBH & CO KG

Germany

High performance with the new DAMBACH conveyor modules for totes, cartons and trays. With decentralized conveying functions and standardized modules, a wide range of material flows can be mapped easily and quickly. All modules are perfectly matched and can be freely combined. Also thanks to the high level of standardization of individual assemblies. This not only increases flexibility, but also reduces spare parts inventories. The comprehensive container conveyor technology modular system consisting of roller cams, lift converters, infeed and discharge conveyors, accumulating roller conveyors, belt conveyors, lifters and leaves nothing to be desired. Our sales department supports you from the planning phase through layout design to implementation. The robust design with integrated cable ducts and sensors ensures maximum functional reliability. Motor rollers and side guides are easily accessible without time-consuming disassembly of the cover.

Request for a quote

DAMBACH LAGERSYSTEME GMBH & CO KG

Germany

The transfer car is based on the innovative DAMBACH Shuttle technology, using power caps for energy storage – making bus bars unnecessary. However, if required a traditional energy supply via bus bar or cable chain is possible. The transfer car can be equipped with up to two load handling devices or with roller or chain conveyors. Good throughput rates Low height Low installation requirements With one or two load-handling units With optional transfer unit for safe transfer of mesh box pallets

Request for a quote

DAMBACH LAGERSYSTEME GMBH & CO KG

Germany

The DAMBACH Vertical Conveyor lifts efficiency to the next level. The free-standing steel construction utilizes warehouse space optimally. The consistent use of poka-yoke techniques and modularcube design allows both fast installation as well as subsequent positioning in confined conditions. Almost any flow of materials can be taken care of with diverse load-handling devices and conveyor elements – two pallets lengthwise or crosswise, a corner transfer module with or without a change of orientation of the conveyed item, and much more. The DAMBACH Vertical Conveyor is one of the highest performing on the market. Each jack can be delivered with preinstallation and decentralized controls. Deepfreeze compatibility up to -28°C comes included at DAMBACH. Compact construction, small lower approach dimensions Inherently stable multiple-column design for heavy loads: up to 3,000 kg Lift speeds up to 240 m/min, lift heights up to 35 m

Request for a quote

DAMBACH LAGERSYSTEME GMBH & CO KG

Germany

DAMBACH lift tables are efficient transfer units for mergers, crossings or branches in flows of materials. Roller or chain conveyors can be integrated as required. The interlocking lift mechanism combined with a rigid frame protects the unit loads and ensures optimum availability. As an option, variable intermediate lift positions can be included to ensure greater flexibility. The compact dimensions and safety guards expand the range of applications. Turntable with Roller or Chain Conveyor Turntables can divide or merge flows of materials without changing the orientation of the unit loads. The highly dynamic turntable drives from DAMBACH are interlocking units and ensure precise rotational angles of up to 270° with any number of intermediate stops. For optimum occupational safety, our turntables can be fully enclosed. In addition, the innovative modular design guarantees numerous and diverse applications and ease of servicing at the same time.

Request for a quote

DAMBACH LAGERSYSTEME GMBH & CO KG

Germany

DAMBACH roller conveyors consist of a stable frame with rollers bolted in place. The rollers are driven by an easily serviced tangential chain drive with tensioning unit housed in a drive enclosure. The entire drivetrain is enclosed for safety and to prevent tampering. Flanged wheels rotate with the rollers to help transport goods carefully. The frame is height-adjustable. DAMBACH chain conveyors consist of self-supporting chain strands mounted on a rigid frame. The number of strands can be varied to suit the application. Duplex chains with straight side plates guarantee careful transport of your goods on an optimised support surface. Chains are supported on low-friction slide rails and can be individually tensioned. All chain strands are driven via a common driveshaft fully enclosed for safety. The mounting frames bolted to the main frames are height-adjustable. High throughput rates Travelling speed up to 0.5 m/s and acceleration up to 0.8 m/s² Max. 1500 kg per storage position

Request for a quote

DAMBACH LAGERSYSTEME GMBH & CO KG

Germany

The MULTIFLEX from DAMBACH sets new standards for throughput, flexibility and efficiency. It comprises three perfectly coordinated modules with seamless interfaces: the proven COMPACT SHUTTLE, the high-performance vertical conveyor LIFT and the newly developed CARRIER. In analogy to the small-part-shuttle technology, the MULTIFLEX enables multi-deep storage and highly dynamic commissioning of various types of pallets. In addition, the compact design of the DAMBACH-shuttles and vertical conveyors ensure a very high storage density. With this modular structure, the MULTIFLEX is flexibly adaptable to different challenges. The fields of application for this pallet-shuttle-system are as variable as its three configurations. It is suitable, for instance for cold storage, buffer storage, dispatch warehouses, sequence storage, commissioning warehouses or supply warehouses – But also for compact warehouses with low throughput.

Request for a quote

DAMBACH LAGERSYSTEME GMBH & CO KG

Germany

The ultra-light COMPACT storage and retrieval machine opens up flexible options for use in existing warehouses. The consistently lightweight design reduces kinematic loads on the floor panels and conserves energy. Transverse forces in the rack are also minimal. A lower approach dimension of 0 millimeters allows the use of conventional stacker racks. No storage space is lost in the lowest rack level. Depending on the application, the COMPACT machines can be equipped with a variety of load handling attachments. High handling capacities and individual location access are achieved with single- or double-deep telescopic forks from DAMBACH. With the patented rotating and swiveling traverse fork, pallets can be picked up or set down at floor level to meet the needs of manual warehouse operation. The tilting device even makes it possible to transport pallets with closed bottoms.

Request for a quote

DAMBACH LAGERSYSTEME GMBH & CO KG

Germany

The rail-guided storage and retrieval machines of our MULTI series are curve-going models and can reach every storage aisle effortlessly via special rails and points—directly, quickly, and safely, and without the need for a costly mechanical traverser. So operations are not interrupted. This clever solution for changing aisles improves access times considerably in any warehouse system. When equipped with suitable load handling elements, MULTI storage and retrieval machines (SRMs) are extremely versatile. They can be supplied as single or twin mast versions for handling practically any type of load, from drinks to car bodies. DAMBACH designs and produces its own load handling attachments tailored perfectly to the respective lifting unit. For example, double-deep telescopic forks for utilizing the available space more effectively, or rotating/traverse forks with adjustable tines for handling closed pallets.

Request for a quoteResults for

Storage-systems - Import exportNumber of results

33 ProductsCompany type