- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- small series

Results for

Small series - Import export

LUTZ PUMPEN GMBH

Germany

The TMB series was specially developed for installation in small systems and apparatus. The single-stage Centrifugal pump offers robust technology in the smallest space. * Drive is via a magnetic coupling * Typical applications: Acids, alkalis, acid and alkali mixtures, solvents, alkaline degreasing baths, electroplating baths, photographic chemicals Features & Advantages * Variable connection options * Compact dimensions, performance in line with requirements * Connections with BSP thread or hose nozzle * Ideal for mobile use * Motor and pump are mechanically separated

Request for a quote

CIC - KLAUS CZERWONKA

Germany

Milling of complex components for automotive and mechanical engineering. Production of prototypes, test parts, small and large series according to data records, drawings, samples or specifications. Machining of cast and forged blanks. Attachment of decorative surfaces.

Request for a quote

SUPER-FILAMENT EINE MARKE DER ADDITIVE MATERIALS GMBH

Germany

Our advanced manufacturing crafts highly precise, custom-engineered components for technical applications in small series. Precision in 3D Construction and Modeling: Expertise in precise 3D construction and modeling underpins the production of technical production parts in small series. Leveraging advanced 3D printing, we create components meeting high standards of accuracy and functionality. Diverse Material Portfolio for Technical Applications: From classic materials (PLA, PET-G, ASA, ABS) to specialized polymers and fiber composites, our varied material portfolio caters to specific needs of technical production parts. Optimized Manufacturing for Small Series: Our techniques ensure efficient, precise production for small series, balancing cost-effectiveness and quality for swift market entry.

Request for a quote

ANTARES LIFE CYCLE SOLUTIONS GMBH

Germany

Our team has many years of experience working with diverse tasks and in diverse industries: For example, product development, product management, international engineering, sample and small-series production, business development, as well as sales and marketing. Our clients can profit from this experience and the tools and methods developed in this context. Our approach is always pragmatic and results-oriented Technical consulting for filtration (utility vehicles, diesel motors, and industry) Screening of product range for suitability for 3D printing Allocation of tasks for product management

Request for a quote

ETIKETTENDRUCK FÖRSTER GMBH & CO.KG

Germany

Labels with variable data individually according to customer requirements If UL certification is required for your barcode labels, this is no problem for Förster Etiketten. We deliver in all formats from small series to large runs on rolls or sheets, or individual labels in the required coding: GS1 GTIN code Barcodes (EAN code or barcode label)Barcodes (EAN code or barcode label) 2D data matrix codes – content from a database Alphanumeric characters from a database Also with results logging on request Other variable data, such as the date of manufacture, can also be subsequently inscribed on the label material or on the laminate at the production site using thermal transfer printing, even in compliance with UL.

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

Semi-automatic machines for single cuts and small seriesWith automatic saw feed and quick-clamping device for the material, the semi-automatic models offer higher cutting output levels and more operating convenience than the manual saw variants. By ensuring fatigue-free working for the operator, they are also suitable for sawing small production runs: Quick-acting pneumatic / hydraulic clamping device Clamping pressure reduction available as option Variable hydro-pneumatically / hydraulically controlled setting of the saw blade feed Easy miter cutting positioning with fixed stop Easy stroke adjustment of the saw unit via 2 clamping levers Well dimensioned worm gear unit with EISELE shock-absorbing feature Quick and easy blade change

Request for a quote

MECHASYS GMBH

Germany

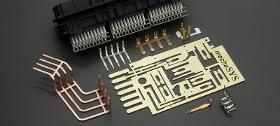

Samples, prototypes and small series made of sheet metal Laser cutting, embossing and bending or punching including electroplating. Prototypes and small series - everything from a single source! We manufacture your individual sample parts, prototypes and small series mostly without any proportionate tool costs. This means that we are very flexible, efficient and cost-effective even with small quantities - in extreme cases from a quantity of 1. This is made possible by our modular bending kit. Everything from a single source: • raw sheets in stock • Laser fine cutting also from pre-punching tape using camera calibration technology • Embossing, bending, folding, pressing • Punching of functional areas • Progressive punching of medium quantities, depending on economic efficiency • Module assembly • CNC laser welding • Complete or partial electroplating by partner.

Request for a quote

MECHASYS GMBH

Germany

Laser cutting or laser fine cutting of metal, we can precisely process all metallic, non-toxic materials in material thicknesses from 0.2 to 2.0 mm. With our high-precision 1kW fiber laser (Nd: YAG with a wavelength of 1064nm) in combination with highly dynamic linear drives, we can produce your laser cuts in copper and brass. Due to our extremely small focus of 0.05mm, we usually create a cutting cag/ clearance of 0.07mm, so that the most delicate contours (especially inner contours) can be realized without mechanical stress, as the processing takes place without contact. This enables high-quality and precise prototypes and small series in contract manufacturing using cutting lasers. Accuracies of +/- 0.01mm, which are required in the sealing area for plastic overmolding for complete plugs or housings. Dimensions: sheet thicknesses from 0.2 to 2.0mm, max. sheet metal of max. 1,250mm x 1,250mm.

Request for a quote

MECHASYS GMBH

Germany

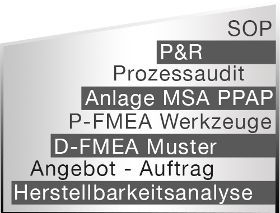

In terms of project management, the respective feasibility study is a matter of course. No offer without a feasibility study. -An offer implies manufacturability; this is how our process is defined! - We live from prototypes and small series. Often there is no second assignment, so there shouldn't be any unforeseen surprises. Or at least only within a manageable framework. The combination of metal and plastic composite parts makes this a challenge from time to time. But you can be sure that here we draw on a wealth of experience that we would like to share with you.

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

The most simple way of welding thermoplastic materials is to use the ultrasonic manual welding device. This is particularly well suited for applications in prototype design, for processing of single products, small series and repairs. Regardless of caulking, swaging, staking, cutting, or spot welding, the HSG ultrasonic manual welding device is easy to use, provides variable power rating, and can be equipped with all types of conventional sonotrodes (35 kHz).

Request for a quote

SCHOCK GROUP

Germany

Precision in toolmaking is crucial for the quality of your products. Our experienced mold-making team manufactures your tools professionally and functionally. Your project is in the best hands at SCHOCK. Our experienced engineers plan all resources with the most modern methods and guarantee on-time production. Furthermore, we provide full lifecycle support for your tools. In mold and toolmaking, we utilize high-quality milling machines, wire and sinker EDM machines, as well as modern CNC-controlled grinding machines. Our service offerings in the field of injection mold tooling include, among others: Injection molds Multi-component molds (rotary tables, index plates, core-back, transfer technology) Insert technology Gas internal pressure (GID) Foil overmolding (IMD) Thermoset molds Prototype and small-series molds Injection molds: up to 1,000 x 800 mm and 2.5 tons Multi-component molds: rotary tables, index plates, core-back, transfer technology

Request for a quote

CHARLY BARON COSMETICS - MINERAL MAKE-UP

Germany

VEGAN MAKEUP BRUSHES Our products are valued and preferred by international professionals in the beauty world. Charly Baron high-performance make-up brushes should not be missing in your brush set. Sustainable & handcrafted in small series, made with the highest quality materials 100% animal hair free! Thanks to our superior Taclon bristles, extreme powder adhesion for economical use of make-up Professional quality and robust design for a long service life of your brushes "Best Body" of all Charly Baron products. Ideally coordinated brush collection

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

Plasma systems from Diener electronic have long since established themselves in a wide range of industrial sectors. With the Atto low-pressure plasma system, you can rely on modern and future-proof cold plasma technology in a vacuum. The chamber volume of approx. 10.5 litres of this plasma system offers enough space to serve laboratory and also small series production. Low pressure plasma treatment is a proven technique for controlled ultra-fine cleaning, adhesion enhancement (activation and etching) and coating of thin films on substrate surfaces. Plasma is generated by applying high-frequency voltage in the vacuum chamber. In the process, the process gas introduced there is ionised. Fields of application: VOC-free cleaning of organic residues Activation before painting, gluing, potting, ...

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

Plasma systems from Diener electronic have long since established themselves in a wide range of industrial sectors. With the Zepto low-pressure plasma system, you can rely on modern and future-proof cold plasma technology in a vacuum. The chamber volume of approx. 1 - 4 litres of this plasma system offers enough space to serve laboratory and small series production. Low pressure plasma treatment is a proven technique for controlled ultra-fine cleaning, adhesion enhancement (activation and etching) and coating of thin films on substrate surfaces. Plasma is generated by applying high-frequency voltage in the vacuum chamber. In the process, the process gas introduced there is ionised. Fields of application: VOC-free cleaning of organic residues Activation before painting, gluing, potting, ...

Request for a quote

SONIKKS® ULTRASONICS TECHNOLOGY GMBH

Germany

The new handwelding gun model is characterized by greater flexibility in handling and application. One advantage, for example, is that the converter is no longer inextricably linked to the gun but can be easily replaced by the customer himself. In addition, it is now possible to turn the sonotrode and converter into the desired working position in just a few simple steps. Moreover, if the working frequency changes, only the converter has to be replaced. The practical ultrasonic handheld welding device is suitable for "mobile" welding of single applications with a straight grip (model HSGG). It is excellently suited for repair, postprocessing, small series production, and for manual workstations in applications such as ultrasonic welding, cutting, rivets, or punching. With its complete synthetic design, it is very light.

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

Plasma systems from Diener electronic have long since established themselves in a wide range of industrial sectors. With the Femto low-pressure plasma system, you can rely on modern and future-proof cold plasma technology in a vacuum. The chamber volume of 2 to 3 litres of this plasma system offers enough space to serve laboratory and small series production. Low pressure plasma treatment is a proven technique for controlled ultra-fine cleaning, adhesion enhancement (activation and etching) and coating of thin films on substrate surfaces. Plasma is generated by applying high-frequency voltage in the vacuum chamber. In the process, the process gas introduced there is ionised. Fields of application: VOC-free cleaning of organic residues Activation before painting, gluing, potting, ... Etching of PTFE, photoresist, oxide layers, ... Super-hydrophobic and -hydrophilic coatings

Request for a quote

ULBRICH GMBH

Germany

Outside – "tool" – rotary table The C-frame press with outside-rotary-table is a tool-change-system in the actual sense. According to the table size as well a the tool-size there could be up to 16 tools installed. Once installed you save expensive change-times with small-series including the full qualitiy control and assurance standards of ULBRICH Q-Control

Do you sell or make similar products?

Sign up to europages and have your products listed

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Change over from O.D. clamping to jaw clamping or centric clamping in 2 minutes – without clamping device change-over and without having to align ? No problem, with the jaw modules. Because the basic unit, into which the jaw module is inserted, is a HAINBUCH chuck or stationary chuck. If at times the clamping head reaches its limits because it must clamp a larger area, then use one of the jaw modules. The 3-jaw module is best suited for round workpieces, and if you have cubic workpieces, then rely on the 2-jaw module. This means that for a large parts spectrum you are completely flexible and always have the solution that is ideally suited for the respective clamping situation. Both are small, lightweight, and can be quickly changed over – an ingenious solution for small-series production.

Request for a quote

ASSFALG GMBH

Germany

The trough vibratory finishing machines are ideally suited for elongated individual parts and small series. Their advantages lie in the machining of heavy, bulky as well as long workpieces and in the contact-free working of sensitive individual parts in chambers. A soundproof cover reduces the noise level and makes working in a workshop possible. The clockwise and anti-clockwise rotation as well as the speed control from 1,200 to 1,500 rpm ensure a wide range of machining options. The unmanned working process is rounded off by the programmable timer. The system can be expanded with an optionally available paper filter and separator. For simple and convenient water treatment, we recommend a paper filter or a fully automatic water treatment system. The process water is pumped into the trough in doses and cleaned in the return flow via a filter fleece or the centrifugal force.

Request for a quote

ASSFALG GMBH

Germany

The tub vibratory finishing machine, which has a size similar to a washing machine, with a fill volume of 70 l is our standard machine and is ideal for prototypes and small series. A noise protection cover reduces the noise and makes it possible to work in a workshop. The right and left-hand circulation as well as speed regulation from 1,500 to 3,000 rpm provide for various processing possibilities. The abrasive material and workpieces are rotated through the generated vibration. The desired processing process is created through the contact of grinding bodies on workpieces. The programmable timer rounds off the autonomous work process. The machine has a modular construction and can be expanded with an optional paper filter and separator. Both are controlled centrally through the control panel on the TV 95-SL. We recommend the PF440 paper filter for simple and comfortable water treatment. The S95 separator simplifies the separation of grinding bodies and workpieces.

Request for a quoteResults for

Small series - Import exportNumber of results

21 ProductsCategory

- Surface treatment - machinery and equipment (3)

- Finishing of surfaces - machinery (2)

- Machine tools, metal machining - parts and accessories (2)

- Prototypes, industrial (1)

- Laser - cutting and welding machines (1)

- Injection moulding of rubber and plastic (1)

- Vehicles - mechanical components and parts (1)

- Cosmetic brushes (1)

- Engines & Parts (1)

- Management training (1)

- Models for the building industry (1)

- Pumps (1)

- Sawing machine tools (1)

- Seals and packing material (1)

- Welding, electric - equipment and supplies (1)