- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- small batch

Results for

Small batch - Import export

EWS WEIGELE GMBH & CO. KG

Germany

The rapid change system EWS-Varia allows to set-up a modern CNC lathe or a turning milling center – and this flexibly. A tool change will just take 20 seconds, which is an unbeatable argument especially in small batch productions whenever it is about reducing the set-up time and thus increasing the productivity. The advantages, however, are also evident in large batch productions. Preset twin tools lie at the machine, thus significantly reducing the down-times. A further advantage is provided by the variety of adaptations; so the optimal tool clamping can be selected for each operation. The inserts available include: Collet chuck holders Weldon/Whistle Notch Milling arbors Morse tapers Hydro extension Shrink adaptations The most important advantage is certainly created by the easy handling. The inserts can be changed with just one hand without counter pressure by the spindle.

Request for a quote

HO-MA GMBH

Germany

With vibration sorting, small batches / quantities can be processed individually up to 200 pieces per minute. Depending on the type of object, we recommend different designs / types – conical, cylindrical or stepped. Surfaces are preferably glass bead blasted or metaline coated (both variants have FDA approval). Mounting types are medium voltage and external voltage.

Request for a quote

ZIMMER GMBH KUNSTSTOFFTECHNIK

Germany

In the area of elastomer technology, the Zimmer Group uses the most modern production processes to manufacture sophisticated workpieces from elastomers. In addition to the transfer molding process, in which the elastomer is placed in a mold, pressed into shape with a die and vulcanized under pressure and heat, we also use the injection transfer molding process. Here, the starting materials are pressed into the mold on an injection molding machine and vulcanize out there. With these two processes, we process a wide range of elastomers such as NBR, silicone, EPDM, FPM or polyurethane. In terms of quantities as well as dimensions, the sky's the limit, because we can manufacture almost any quantity required, from special solutions in quantities of one to medium-sized small batches and large series of more than 10,000 units.

Request for a quote

OPSYTEC DR. GRÖBEL GMBH

Germany

We offer LED technologies for existing applications. With our modular concept, combined with our calibration laboratory and in-house production we offer decisive development advantages. POSSIBLE REASONS FOR CUSOMIZED UV-LED: The system already exists. Standard products can’t be installed due to limited space. Irradiation from one direction is not sufficient The determination of irradiation wavelength has not yet taken place You are looking for a competent and independent partner YOUR ADVANTAGES WITH OPSYTEC UV-LED CUSTOMIZED SOLUTION: Development and production from a single source Ideal for small batches, tests and prototypes Wavelength 275 nm, 365 nm, 385 nm, 395 nm and 405 nm available Further wavelengths are possible Suitable sensor? We offer customer-specific solutions, too Reliable results through our own calibration laboratory Special solutions are beneficial - even for small quantities. Ask us!

Request for a quote

BOLZ PROCESS TECHNOLOGY GMBH

Germany

Chemical Design - Series V 630 - 1600 TC The classical HEINKEL top discharge centrifuges are a cost-effective alternative in chemical manufacturing. The centrifuge can be easily adapted to the product characteristics and is therefore suitable for companies that manufacture a variety of products in small to large batches. Special properties for the benefit of the customer: Flexible adaptation for difficult to filter products Lossless filter cake discharge Gentle solids discharge without particle destruction Excellent washing and extraction effect Simple centrifuge design Reliable system for removal of the filter bag Rugged and simple system for the detachable border ring

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SERVOLIFT GMBH

Germany

SERVOLIFT laboratory blenders are ideal for producing small batches under production conditions. This is possible through the container’s geometry, which is adapted from the large production blender. The knowledge gained from blending tests creates a reliable basis for later manufacturing. Parameters such as RPM and time can therefore be varied. Small size - large effect Technical description Compact blender, ideal for product and process development Operate on a control or touch panel Design and geometric relationships correspond to the large production blenders Also available as test and loan unit

Request for a quote

SERVOLIFT GMBH

Germany

These blenders are especially well-suited to the area of pilot facilities, small batches, production as well as test. Its flexibility results from the various designs, such as mobile or stationary, as well as the use of exchangeable blending containers, such as containers, round tanks, double cones and V-containers. It can be expanded through installations and conversions of choppers, spray systems and NIR systems. More than just blending Technical description Load capacity: 150 kg Protective hood, Macrolon plate in an enclosed stainless steel frame Non product contact material AISI 316L / AISI 304, Ra < 1.4 μm Product contact material AISI 316L, Ra < 0.8 μm Blender individually exchangeable: Container, drum, double cone, special containers Further optional functions: Spraying system, NIR, active tools Blending drive: frequency-controlled worm drive brake motor, blending RPM: 5-20, adjustable Blending time 0-99 min., adjustable Control: PLC, Siemens S7 operation, touch...

Request for a quote

TAMPOPRINT GMBH

Germany

A real Plug-and-Play fully automated system which is ready to use anywhere at any time. You only need electricity, gas and air supply, then connect our CLOSURE PRINT COMPACT and production may start. No service technician for commissioning and no special qualified personnel at the customer are necessary. A high-precision, space-saving rotary pad printing fully automated system for small batch sizes. Feeding solution, parts transport for further processing to the point of a complete system solution − everything from one source.

Request for a quote

OPTIMA PHARMA GMBH

Germany

All commercially available ready-to-use syringes (glass and plastic) All commercially available safety devices Simple operation Appropriate for small batch production and laboratory applications Continuously working Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

BORRIES MARKIER-SYSTEME GMBH

Germany

BORRIES stamping machines can be used in a workshop for single, small batch and batch production. They are adaptable for almost every deformable material. Because of the big usable stroke workpieces with different heights can be marked without any adjusting. The easy handling, the well-engineered construction and the large range of marking stamps offer a lot of different application areas and make the BORRIES stamping machines to an indispensable tool.

Request for a quote

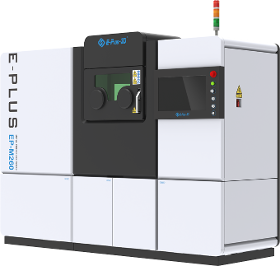

EPLUS3D TECH GMBH

Germany

The EP-M260 is an industrial grade metal 3D printer that uses advanced metal powder bed fusion (MPBF) technology. It is capable of easily and quickly converting CAD data into high-performance, complex structure metal parts. The 3D printer is an ideal choice for medium sized parts and small batch production.

Request for a quoteResults for

Small batch - Import exportNumber of results

12 ProductsCompany type