- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- servo drives

Results for

Servo drives - Import export

NIDEC GRAESSNER GMBH & CO. KG THE GEAR COMPANY

Germany

The design of the Dyna Gear range has been infl uenced by extremely varied applications within many industry sectors. The Dyna Gear range has been developed with a highly dynamic servo drive solution in mind and therefore benefi ts from many advantages. Dynamic and Precision in small format - our new size Dyna Gear D37 is designed for highly dynamic servo drive solutions in compact applications.

Request for a quote

NIDEC GRAESSNER GMBH & CO. KG THE GEAR COMPANY

Germany

The design of the Dyna Gear Economy range has been infl uenced by extremely varied applications within many industry sectors. The Dyna Gear Economy range has been developed with a dynamic servo drive solution in mind and therefore benefits from many advantages. Right angle gearbox, single-stage, ratios 5:1, 8:1, 10:1 and 15:1. The compact and rigid design ensures highest performance whilst being space and weight efficient. Lubricated for life, the gearboxes are virtually maintenance-free (when used under normal conditions). The high efficiency rating of up to 96% saves energy costs.

Request for a quote

NIDEC GRAESSNER GMBH & CO. KG THE GEAR COMPANY

Germany

Designed for special requirements – no adaption, no compromises: There are decades of engineering expertise of MS-Graessner in the newly developed Power Gear HS series. Thus each individual component was consistently developed and designed to meet the requirements at the highest speeds. With a multitude of benefits for a variety of applications and fields of application. Gearbox for highest speeds For dynamic servo drive-train units Higher permissible thermal performance limit Low backlash and high accurate transmission Motor mounting via coupling an lantern Friction-locked fit between shaft and bevel gear Suitable as pre-stage for coaxial gearboxes Energy-saving due to high efficiency rating of 98% Technical overview Sizes S90, S110, S140, S170 Configurations L, H, KL, KH Ratio i = 1,0 / 1,5 / 2,0 Shaft arrangement WA 1, WA 3, WA 13 Input speed n 1max up to 8500 min -1 Motor mounting Via coupling and lantern (KL/KH)

Request for a quote

ETH MESSTECHNIK GMBH

Germany

Metal Bellows Coupling with split hubs Backlash-free metal bellows coupling with split hubs For shaft diameters from 10 – 80 mm High torsional stiffness, compensation of shaft misalignment at low restoring forces Radial assembly! Due to the split hub design shafts can be mounted and adjusted before the assembly of the coupling Perfect bellows coupling for servo drives, e.g. in testing equipment, automation techniques, packing machines Torque range: 18 – 1400 Nm

Request for a quote

ETH MESSTECHNIK GMBH

Germany

Miniature Metal Bellows Coupling axial pluggable, with collet clamps Backlash-free miniature metal bellows coupling with clamp hubs For shaft diameter from 3 – 25 mm High torsional stiffness, compensation of shaft misalignment at low restoring forces Easy assembly with friction-locked clamp hubs Perfect bellows coupling for encoders, tachometers, potentiometers, servo drives, NC axis, stepper motors Torque range: 0,5 – 10 Nm Axial pluggable

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ETH MESSTECHNIK GMBH

Germany

Miniature Metal Bellows Coupling with collet clamps Backlash-free miniature metal bellows coupling with clamp hubs For shaft diameters from 1 – 25mm High torsional stiffness, compensation of shaft misalignment at low restoring forces Easy assembly with friction-locked clamp hubs Perfect bellows coupling for encoders, tachometers, potentiometers, servo drives, NC axis, stepper motors Torque range: 0,1 – 10Nm

Request for a quote

ETH MESSTECHNIK GMBH

Germany

Metal Bellows Coupling axial pluggable Backlash-free metal bellows coupling as axial pluggable execution Easy assembly / disassembly by simply plugging / pulling the coupling parts High tensile aluminum and special coatings ensure a durable solution at low mass / inertia For shaft diameters from 10 – 70 mm High torsional stiffness, compensation of shaft misalignment at low restoring forces Perfect bellows coupling for servo drives, e.g. in testing equipment, automation techniques, packing machines Torque range: 18 – 500 Nm

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

The longitudinal plate saw LPS-T from BEHRINGER is a true specialist in its field. It is particularly suited for sawing small, compact parts and short offcuts of the kind required in toolmaking shops. The LPS-T also makes fast, neat work of test cuts and notching operations in materials with difficult machining properties. Making all this possible is a traversable table which allows the rapid positioning, alignment and clamping of workpieces. The material table is fitted with T-slots over its entire length, allowing even awkwardly shaped workpieces to be securely held in place by the flexible use of clamping fixtures. The LPS-T is able to cut even materials with different machining properties with the utmost precision without compromising on speed. This is made possible by a durable design in combination with vibration-damping grey cast iron components. Saw feed is performed here by a ball screw with servo drive and the sensitive BEHRINGER cutting pressure control system.

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

BEHRINGER vertical bandsaws are the perfect answer when it comes producing cuts in all plate dimensions and thicknesses with optimized contours and machining allowances. LPS bandsaws can be ideally tailored to meet your specific needs. The material table is structured using platform technology and can be variably equipped in 250 mm graduations with cover plates, liftable roller conveyor segments, recesses for crane loading on chains or measurement and clamping devices. Every machine is unique to its owner. The LPS vertical bandsaws are able to cut even materials with different machining properties with the utmost precision without compromising on speed. This is made possible by a durable design in combination with vibration-damping grey cast iron components. Saw feed is performed here by a ball screw with servo drive and the sensitive BEHRINGER cutting pressure control system.

Request for a quote

COSY ELECTRONICS GMBH

Germany

Normally two separate connectors are used for power and signal lines for servo drives. The new reduced size connection system from ITT Cannon combines power and signal lines into one zinc die-cast housing. This reduces the number of individual components as well as the cabling time and costs are cut. The innovative design simplifies the assembly and is a plus factor compared to the solution with circular connectors, with 50% less weight and size. For these reasons it is the ideal connection system for applications where there is not much space available. The CmX series fulfils all requirements according to DIN EN 61984. There are three sizes: Cm2, Cm3 and Cm5 with 16 up to max. 30 contacts.

Request for a quote

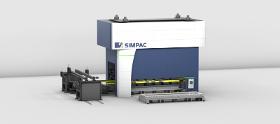

SIMPAC EUROPE GMBH

Germany

SIMPAC presses with servo direct drive stand for highly dynamic forming processes and offer maximum flexibility in the production. In combination with a high stiffness value of press body and drive, they deliver consistently high part quality. Overview: ● Press capacity: 3,000 - 10,000 kN ● Part size: small to medium ● Slide kinematics: servo (freely programmable) ● Application: stamping, cutting, bending, embossing, drawing, integration of subsequent processes Features and benefits: ● Dynamic processes through the use of torque motors that provide high torque even at low speeds ● Maximum production flexibility due to freely programmable slide movement, slide velocity and stroke length ● Significantly higher output compared to conventionally driven presses due to reversing pendulum movement of the slide ● Very solid, FEM-calculated and low stress annealed press body

Request for a quote

SIMPAC EUROPE GMBH

Germany

SIMPAC presses with servo direct drive stand for highly dynamic forming processes and offer maximum flexibility in the production. In combination with a high stiffness value of press body and drive, they deliver consistently high part quality. Overview: ● Press capacity: 8,000 - 30,000 kN ● Part size: medium to large ● Slide kinematics: servo (freely programmable) ● Applications: stamping, cutting, bending, embossing, drawing, integration of subsequent processes Features and benefits: ● Dynamic processes thanks to the use of torque motors that deliver high torque even at low speeds ● Maximum production flexibility through free programmability of slide movement, (forming) speed and stroke lenths ● Significantly more output compared to conventionally driven presses due to reversing pendulum movement of the slide ● Very solid, FEM-calculated and low stress annealed press body

Request for a quote

OPTIMA CONSUMER GMBH

Germany

Characteristics: - Highest dosing accuracy - Precise closure parts assembly - Flexible servo drives - Turning station with torque control - Greatest possible efficiency - fAccurate transfer at discharge Options: - f100% leak test - Check weighing - Automatic sorting and feeding systems - Die-cut module for lid - Gassing - Ultrasonic sealing - Laser coding - Container cleaning

OPTIMA CONSUMER GMBH

Germany

Characteristics: - Packaging material flexibility - High precision portioning for constantly good beverage taste - High levels of line efficiency - Modules with servo drive for low-noise packaging operations - Ideal access for cleaning or maintenance - High level of flexibility due to modular construction and servo drives - Process lanes can be switched off separately Capsules: - Cylindrical shape - Bulk goods for sorting and fully automatic feeding - Multi-lane transport - Gentle processing of packaging material - High operational safety Basic function of the packaging machine: - Capsule transport on up to 12 lanes for high performance - High precision portioning via auger filler - Flexible product compaction with servo press - Closing with self-monitoring ultrasonic sealing - Check after each processing step

Results for

Servo drives - Import exportNumber of results

15 ProductsCompany type