- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- test bench

Results for

Test bench - Import export

EP EHRLER PRÜFTECHNIK ENGINEERING GMBH

Germany

We offer you standardised complete systems for the measurement of volume & mass flows. We use measuring elements that have established themselves within previously built customer-specific test benches and convince with high measuring accuracy. We develop and manufacture Venturi tubes and nozzles as individual components or as VMF® complete systems. The VenturiMasterFlow® measuring system, VMF® for short, is used for the precise measurement of air or gas volume and mass flows of 100,000 m³/h. The core of the VMF® system is the FlowProcessor, a PC system with the corresponding data acquisition hardware. Venturi nozzles convince by a low remaining pressure loss and are suitable for flow measurement of gases with high temperatures. The software developed under LabVIEW is operated either via touch screen or with mouse and keyboard.

Request for a quote

CIC - KLAUS CZERWONKA

Germany

control panels, control cabinets, pneumatic systems, pneumatic systems, control units, pre-assembled pneumatic modules for machines and plants in automation technology factory automation assembly lines test benches Also for automotive applications such as brake test benches, assembly robots, conveyor belts. Design, layout, assembly, plug and play delivery. We are also happy to use components according to the parts list, specifications or customer specifications.

Request for a quote

EP EHRLER PRÜFTECHNIK ENGINEERING GMBH

Germany

In order to guarantee that components such as valves, pumps, hoses and other components or component groups are free from leakage, leakage measurements are carried out. We offer leakage test benches for different pressure ranges in both the low and high pressure range.

Request for a quote

EP EHRLER PRÜFTECHNIK ENGINEERING GMBH

Germany

The EP endurance test benches are used to test various components over a defined cycle for durability, e.g. temperature and pressure cycle tests. A high series quality requires precision and reliability. Operational and endurance tests are necessary in order to be able to demonstrably guarantee high quality. In the form of selection or random sampling tests, components are tested for fatigue and wear by means of load tests, for example under pressure and temperature changes. The tests are used for endurance stress testing of various materials and products with different pressure curves and temperatures. We build test benches according to your requirements: e.g. for long-term or short-term tests, under static or pulsating test conditions and depending on other factors. Present us your requirements!

Request for a quote

EP EHRLER PRÜFTECHNIK ENGINEERING GMBH

Germany

Apparatus for pressurizing test pieces We offer burst test benches to test load-bearing elements under pressure for their resilience. The components to be tested are put under pressure until they burst. Depending on the requirements (e.g. depending on the medium, pressure range, static or pulsating tests) we build your customized test stand.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

EP EHRLER PRÜFTECHNIK ENGINEERING GMBH

Germany

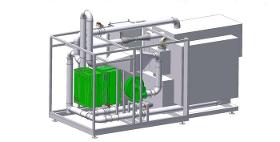

With our HPT heat pump test bench you can simulate humidity as well as temperature. The test stand is used for functional testing of air-to-water heat pumps according to DIN EN 14511. Current test systems on the market, which are used to test e.g. air-to-water heat pumps, are climatic chambers with a cooling, heating and humidification unit fixed to the roof. The disadvantage of this concept is that it is not possible to set a homogeneous temperature and humidity distribution in the cube-shaped room. Based on test engineering concepts in the automotive industry, EP-E developed a concept in which the air flows in a closed loop (loop design). The HPT heat pump test stand is a closed-loop test stand for functional testing of air-to-water heat pumps according to DIN EN 14511. The advantageous closed-loop design uses an insulated chamber with conditioning units for temperature and humidity outside the chamber.

Request for a quote

EP EHRLER PRÜFTECHNIK ENGINEERING GMBH

Germany

The test bench is designed for calibration with critically operated nozzles of domestic gas meters or others such as diaphragm gas meters, ultrasonic meters, thermoelectric gas meters. The test bench is specially designed for the calibration of domestic gas meters (bellows gas meters, ultrasonic meters, thermoelectric gas meters). The test bench is modular - 1x6 to 4x6 clamping positions for the gas meters can be combined. Due to the modular design 1 to 12 gas meters can be tested simultaneously. In parallel, up to twelve additional test pieces can be adapted, run in and leak tested. A magazine consisting of three critical nozzles is used as flow transmitter. Optionally, a nozzle drum with nine combinable nozzles can be used. This allows the generation of up to 512 different flow points with highest accuracy.

Request for a quote

EP EHRLER PRÜFTECHNIK ENGINEERING GMBH

Germany

We offer you standardized complete systems for the measurement of volume & mass flows. We use measuring elements that have established themselves within previously built customer-specific test benches and convince with high measuring accuracy. The SMF® series of nozzle test benches has been specially developed for calibration with air. Critical nozzles are used as measuring elements. Up to 18 critical nozzles can be combined, depending on customer requirements. EP offers different designs for the register: Drum Design, Block Design & Register Design. Another variant is a mobile system: The EP SMF® - Mobile Flow Calibrator - a compact measuring system for flow calibration. EP Ehrler Prüftechnik manufactures single nozzles in the flow rate range from 0.005 to 2000 m³/h. In addition to our standard range, we also manufacture customer-specific nozzles that are perfectly designed for your application in compliance with DIN EN ISO 9300*.

Request for a quote

EP EHRLER PRÜFTECHNIK ENGINEERING GMBH

Germany

With the purge air method, heat recovery for balanced air mass flows can be determined for alternating, decentralised ventilation units. The uncertainties of the direct measuring method used so far due to inhomogeneous velocity and temperature profiles at the outlet of the ventilation units are circumvented by the scavenging air method and the measuring accuracy is higher. With the optional humidity conditioning the moisture recovery can also be determined. Further thermal performance indicators are the air volume flow in alternating operation and the balance, which can also be determined with the test bench. The test stand is equipped with an auxiliary fan so that continuously operating ventilation units can also be measured with the direct measuring method.

Request for a quote

EP EHRLER PRÜFTECHNIK ENGINEERING GMBH

Germany

The high-precision calibration laboratory is accredited according to DIN EN ISO/IEC 17025 for flow calibration of flowing gases. The EP calibration laboratory is accredited by the DAkkS according to DIN EN ISO/IEC 17025:2005 for calibrations of gases in-house and on-site under the procedure number D-K-21444-01-00. We offer calibrations for gas flow measurement as well as temperature, humidity and pressure measurements. In addition, we calibrate all measured variables of the test bench directly at your site. Our experienced technicians also check the harmonious interaction of all sensors, so that the entire system is perfectly tuned. The opening of our new calibration laboratory in Asia enables us to offer you even better service internationally.

Request for a quote

OPTOLUTION MESSTECHNIK GMBH

Germany

Large heat and flow meters are often used continuously for decades after an initial calibration at external test benches. A recalibration of these meters within their actual operation conditions was not possible so far. In the best case scenario those flow meters are unmounted and recalibrated on an external test bench. Drawback of this method is an interruption of supply in addition to its already high costs. Furthermore, calibration conditions can differ greatly from actual operation conditions compared to test bench conditions, so even if calibrated, the measurement uncertainty in operation remains fairly unknown. This often leads to more difficult fluid distribution optimizations and leaves billing fairness to a gamble. More precisely measured values of flow sensors may uncover hidden saving potentials within the fluid distribution system and allow more exact performance indicators, improving energy efficiency.

Request for a quoteResults for

Test bench - Import exportNumber of results

12 ProductsCompany type

Category