- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- segments

Results for

Segments - Import export

KULLEN-KOTI GMBH

Germany

The brush cores are made of special reinforced polypropylene making them light, resistant to acids and alkalis and suitable for use in the food industry. The range of options is extensive. All in all we offer seven standard core diameters with three fill density variations each: low, medium, and high - making a total of twenty one standard cores to choose from. Almost all fill material qualities can be used. To assemble a complete roller brush is remarkably quick an easy as it does not involve any complicated mechanical connections, simply slide the brush segments on to the brush shaft and secure them in position with two locking collars. By standarding the sizes of our brush cores we are able to offer lower unit prices and faster delivery times. But the fact that our brush carrier sizes are standardised certainly does not mean that the choice we offer is limited. If required the standard internal bore diameter of the brush segments and locking collars can easily be reduced by...

Request for a quote

DEUTSCHES METALLFASERWERK DR. SCHWABBAUER GMBH & CO. KG

Germany

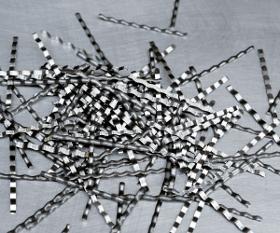

Material: low carbon steel We produce our corrugated STAX segment wire steel fibers in the lengths of 50 mm and 34 mm. Application for our STAX segment wire steel fibers you find in industrial concrete floors and plates.

Request for a quote

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

The servo X 800 are the most flexible and powerful of film packaging machines in the horizontal large-format segment – and all this with maximum modularity. They can be configured individually and thus meet all requirements. Whether chain infeed or infeed conveyor, servo X 800 machines win over with their continuous packaging process and no stop-and-go, meaning dead time is not an issue when sealing. Besides high performance, this enables extremely tight-fitting and precise packaging with a saving in film of up to 15 %. This ensures that the film packaging‘s excellent appearance is unrivalled.

Request for a quote

BOLZ PROCESS TECHNOLOGY GMBH

Germany

BSV Series DN 100 – 400 The Ball Segment Valve, BSV for short, is the result of a development of an innovative valve for pharmaceutical and fine chemical processes. For a wide range of solids applications, it is the preferred valve for process equipment like vacuum dryers, reactors or centrifuges as both as inlet and discharge valve. Even if products are not free flowing, have an abrasive effect or have moist and adhesive properties, the Ball Segment Valve is the right choice as a reliable, vacuum and pressure-tight process valve. The internal corner-free and edge-free housing does fullfill your cGMP requirements and leaves the ball segment sufficient space to move clear of the product flow path when opened. A reactor agitator or mixing tool can be designed to move within a few millimetres of the Ball Segment Valve virtually eliminating dead-space in the process area. Besides the standard flanges, the BSV can be equipped with tailored and non DIN flange connections to suit most...

Request for a quote

BOLZ PROCESS TECHNOLOGY GMBH

Germany

Description Ball segment valve TD 250 PN10 – 250 PN6 – TD 250 PN10 Free pass 231mm Year of construction 2013 Manufacturer HEINKEL Product contacted material 1.4404 / 316 L Control and drive system FESTO Double-acting Type DAPS-0480 Incl. Switchbox with Limit switches from Pepperl und Fuchs. Seal design EPDM, E70H white (FDA conform), on request Viton and Perlast also available. Comment 1 piece available, unused Ex design II 2/2 D c T135°C X , II 2/2 G c IIB T4 X Inlet flange Flange with tapped holes DIN outer Ø 395mm, PCD 350mm with 12 x M20 Outlet flange Flange with tapped holes DIN outer Ø 395mm, PCD 350mm with 12 x M20 Minimal und maximum allowable pressure -1 to +6 bar Minimal und maximum allowable temperature -10 to 130°C Surface quality Inside, product-contaminated Ra < 0,8 µm; Outside, none product-contaminated RA < 3,2 µm Extra Equipment Inspection port with blind cover, incl. FAT protocol and documentation

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

The segmented clamping bushing SE with the hexagon socket sits on the clamping pyramid, absolutely form-fitted in every clamping position and thereby enables maximum machining performance with minimal vibration and thus less tool wear. The full-surface contact of the segmented clamping bushing on the mandrel ensures a significantly better insensitivity to contamination than previous segmented clamping bushing/mandrel systems. Therefore, these segmented clamping bushings are even better suited for raw material, cast and forged parts, as well as fine-particle non-ferrous metals such as brass. And they offer this suitability at run-out of ≤ 0.01 mm and in the premium version at ≤ 0.007 mm.

Request for a quoteResults for

Segments - Import exportNumber of results

7 ProductsCompany type