- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- sawings

Results for

Sawings - Import export

BIZERBA SE & CO. KG

Germany

Flexible sawing system for industrial food production The FK 32 is made entirely from stainless steel and with top quality construction all round. Depending on production environment and food to be processed this saw is available with a variable work area or can be mobile. Ergonomic and effective comminution and portioning of fresh and frozen foods. Area of Use Suitable for fresh fish as well as for frozen meat Products with bones such as shanks / osso buco and soup bones Production of same weight portions such as cutlets Due to its design and numerous variants it is the perfect tool for industrial use

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

The automatic plate saw VPS60-160A is BEHRINGER's solution when it comes to fully automatic cross-cutting of large plates and blocks. The vertical arrangement of the saw band has clear advantages over the horizontal design, as the engagement length of the saw band is significantly shorter. As a result, the cross cutting plate saw offers significantly higher cutting capacities while at the same time reducing tool costs. Thanks to their robust basic design and high-performance components, the automatic plate saws of the VPS series are designed for demanding applications in the steel trade, industry and metal production. From non-ferrous metals and aluminum to simple work steels and difficult-to-cut materials such as Inconel or titanium. Their modular design allows the cross cutting plate saw to be individually adapted to the customer's application.

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

The VA-L series aluminium saws define a whole new performance class with their design. Servo-driven axes and a harmonic drive gear guarantee high-performance and process-reliable operation from aluminium alloys to copper and brass alloys. Due to the technical features and the associated sawing performance, the sawing results meet requirements regarding the surface of Rz < 8 µm and cutting tolerances < 0.1 mm. In many cases, further processing of the surface is therefore no longer necessary. All components of the aluminum circular saws and their processes are designed with this in mind. On the one hand, this includes material processing in terms of chip flow and minimum rest piece length, but also machine components of the latest generation. The VA-L aluminium saws are equipped as standard with pneumatic short-stroke cylinders for material clamping and do not use any hydraulics.

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

The flexible PC-controlled high-performance circular sawing system PSU 450 A is designed for the utmost cost-effective production of small and large quantity runs. • The PSU 450 A features up to three servo-motorized axis to ensure a precise positioning with regard to length, mitre angle setting and output gripper unit • The material to be cut off is held by means of the output gripper unit. After the cut, the cut piece is removed from the working area in axial direction and put at a defined place. • Extraordinarily short cycle times due to the hydraulicallycontrolled saw stroke • A standard feature in the saw is an innovative, dynamic saw drive technology that ensures premium cutting results.

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

The VMS automatic machines are designed for the ultimate handling simplicity - both for series cuts and in manual operation. The machine operation takes place using a convenient NC control. Where your operations call for frequently changing single cuts, an optional bar start detection system makes for even simpler material handling through fully automatic length positioning without the need for manual intervention. The generously dimensioned casing complies with the latest safety requirements and can be fully opened for improved access. — Material feed with flat guide and ball screw spindle for high-precision positioning — Large-dimensioned cover hoods meet highest safety standards — Easy to operate in automatic and manual operating mode — Can be combined with roller conveyors — 4 speeds as standard for machining almost any steel quality — Both coolant and micro spray system standard

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

The HCS MULTI-FLUID is a series of carbide circular saw manufactured by Eisele. The key highlights of the HCS MULTI-FLUID series include a firm base frame that is welded, a bigger scope of cutting, an arbitrary saw blade that is accessible to ensure maximum cutting scope that can reach up to 180 mm . The machine has a sturdy and robust base frame on which the combined sawing unit and material feed unit are mounted. This structure combined with a very robust machine design ensures a smooth sawing process with excellent cutting results and a long service-life of the saw blade. The Multi-Fluid system is excellent for high-alloy stainless steels and tool steels, nickelbasedalloys like Inconel and Hastelloy as well as titanium alloys. Depending on the requirements, the following cooling/lubrication components can be combined in a most effective way: — Coolant nozzles for wet processing — Micro-spraying device for minimum quantity lubrication — Cooling vortex tube for dry cutting

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

EISELE has launched the PSU 450 that is versatile and simple when it comes to handling. For its flexibility, the automatic mitre adjustment and feed gripper are made. It can be paired with infeed magazines and disposal machine due to its structure. This product is robust and durable. Its standard sawblade is 450 mm long. he solid machine base ensures a vibration-dampened and low-noise sawing process. This achieves excellent cutting performance as well as high saw blade life.

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

The PSU 450 GS is a circular saw specially designed for sawing curved tubes such as mufflers, hydroforming or exhaust pipes. Standardised mounts and their flat material table enable individual workpiece fixtures to be accepted. The saw entry and exit point can be freely adjusted accordingly. The standard two-hand operation allows comfortable and safe working without disturbing mechanical guards. The heart of the PSU tube cutting saw is the worm gear unit with EISELE shock-absorbing feature, produced in-house. It is heavy duty and provides for a smooth, low-vibration running of the saw, which, of course, has a positive impact on the quality of the cutting surface and the blade life. + Mounting for part-specific fixtures + Adjustable saw entry and exit point + Robust and durable + Micro spray system

Request for a quote

BIZERBA SE & CO. KG

Germany

The FK 23 is made entirely from stainless steel and with top quality construction all round. Ergonomic and effective comminution and portioning of fresh and frozen foods. Suitable for fresh fish as well as for frozen meat Products with bones such as shanks / osso buco and soup bones Production of same weight portions such as cutlets Due to the wide range of saw blades high quality products such as fine fish or matured beef can be processed by accurate weight and optically appealing

Request for a quote

BIZERBA SE & CO. KG

Germany

Flexible sawing system for industrial food production The FK 32 Heavy Duty Meat and Bone Saw is made entirely from stainless steel with high IP protection and with top quality construction all round. Depending on production environment and the food to be processed, this saw is available with a variable work area or can be mobile by adding optional stainless steel wheels. Ergonomic and effective Heavy Duty Meat and Bone Saw cutting and portioning of fresh and frozen foods. This unit will easily cut through fresh and frozen fish as well as heavy cuts of frozen meat including the bones. The Heavy Duty Meat and Bone Saw is ideal for industrial use and has a number of optional extras that you may want to consider to include a Sliding table with removable remnant holder additionally a Stainless steel bench type stand with feet a Mobile CE compliant version, Special saw blades depending on the material that needs to be cut. Safety features. Safety In designing the Heavy Duty Meat and...

Request for a quote

BIZERBA SE & CO. KG

Germany

Compact meat and bone saw for sales counter or preparation room The FK 23 Meat and bone saw is made entirely from stainless steel and with the very best quality construction all round. Ergonomic and effective cutting and portioning of fresh and frozen foods. Multiple saw blades are available all with the Bizerba quick, easy safe blade change system. Suitable for left and right handed operations. Even the saw wheel can be removed, cleaned and replaced without the need for tools. The total protection type is IP55. Additionally this unit can be supplied with a larger work bench and alternative special saw blades depending on your personal requirements. If you are a butchers looking to cut heavy and even frozen carcasses then this will be the ideal solution. Alternatively the system will also cut delicate fish products or matured beef products gently with ease. Easily cut products safely without effort 250 millimetres in height and up to 190 millimetres in width. If you require a...

Request for a quote

BIAX - SCHMID & WEZEL GMBH

Germany

The robust and established alternative in metal housing. Very popular due to the high tractive power of the reciprocating engine.

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

The longitudinal plate saw LPS-T from BEHRINGER is a true specialist in its field. It is particularly suited for sawing small, compact parts and short offcuts of the kind required in toolmaking shops. The LPS-T also makes fast, neat work of test cuts and notching operations in materials with difficult machining properties. Making all this possible is a traversable table which allows the rapid positioning, alignment and clamping of workpieces. The material table is fitted with T-slots over its entire length, allowing even awkwardly shaped workpieces to be securely held in place by the flexible use of clamping fixtures. The LPS-T is able to cut even materials with different machining properties with the utmost precision without compromising on speed. This is made possible by a durable design in combination with vibration-damping grey cast iron components. Saw feed is performed here by a ball screw with servo drive and the sensitive BEHRINGER cutting pressure control system.

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

Automatic longitudinal plate cutting or with automatic 90° band rotation for combined longitudinal and cross cutting: the BEHRINGER range of vertical plate saws provides high performance and the ultimate in flexibility. A durable, torsionally rigid welded construction and vibration damped cast components provide the assurance of minimized noise and precise cuts – no matter whether you are processing parts or strips. From NF metals and aluminium through steel to inconel or titanium. LPS vertical bandsaws from BEHRINGER will cut through even the most difficult of materials with the utmost precision – without compromising on speed. This is made possible by a durable, torsionally rigid welded construction in conjunction with vibration damped cast components. The saw feed system is equipped with servo technology together with the sensitive BEHRINGER cutting pressure control system for guaranteed higher cutting outputs and a longer band service life.

Request for a quote

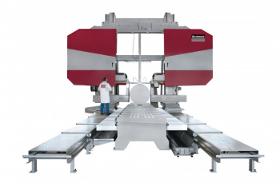

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

The HBP1100 - HBP1500 / HBP1100A - HBP1500A are series of semi-automatic and automatic large bandsaws manufactured by Behringer. The large-scale universal machines from BEHRINGER can handle any job that is needed. Their expertise: Handling heavy-duty workpieces with ease and slicing through the material with extreme cutting performance. When processing long solid workpieces – rolled or rough turned – or processing large pipes, these benefits make for dramatic improvements in productivity. Round or rectangular – the results are equally impressive. In the BEHRINGER semi-automatic models, the material is positioned by eye, for instance with the aid of a line laser. For longer cut piece lengths, we recommend using a measuring device for precise positioning. The use of a feed gripper allows automatic sawing of solid material or pipes.

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

This Behringer's semi-automatic straight-cutting bandsaws combine the high-cutting output and simple handling which are utilized for economical processing of low piece numbers and one-off cuts. They feature easy handling that are precised in isolating the easy and difficult cuts. These machines are suitable in cutting pipes and all the materials which contain difficult machining properties and they can also provide semi-automatic variants that are recommended for the accurate positioning of a longer cut piece.

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

The automatic mitre bandsaws from BEHRINGER are saws to really get things moving. Particularly when it comes to classical series production such as cutting to fixed lengths and mitre sawing in automatic mode. And also when cutting layers and packages they make a good impression. By their excellent cutting performance and short nonproductive times, your productivity can be increased significantly. Using an NC controlled feed gripper in conjunction with an NC controlled saw frame mitre box, fully automatic mitre cuts can be performed on both sides. The PC control system provided as standard makes for extremely simple menu-prompted operation of the saw and peripheral devices. The BEHRINGER mitre bandsaws contain many useful features already in the basic price: - Convenient PC control - Fast NC-controlled mitre system - Vertical clamping unit - NC-controlled feeding gripper with 3.000 mm feeding length in single stroke - Spray mist cooling system

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

BEHRINGER vertical bandsaws are the perfect answer when it comes producing cuts in all plate dimensions and thicknesses with optimized contours and machining allowances. LPS bandsaws can be ideally tailored to meet your specific needs. The material table is structured using platform technology and can be variably equipped in 250 mm graduations with cover plates, liftable roller conveyor segments, recesses for crane loading on chains or measurement and clamping devices. Every machine is unique to its owner. The LPS vertical bandsaws are able to cut even materials with different machining properties with the utmost precision without compromising on speed. This is made possible by a durable design in combination with vibration-damping grey cast iron components. Saw feed is performed here by a ball screw with servo drive and the sensitive BEHRINGER cutting pressure control system.

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

Semi-automatic machines for single cuts and small seriesWith automatic saw feed and quick-clamping device for the material, the semi-automatic models offer higher cutting output levels and more operating convenience than the manual saw variants. By ensuring fatigue-free working for the operator, they are also suitable for sawing small production runs: Quick-acting pneumatic / hydraulic clamping device Clamping pressure reduction available as option Variable hydro-pneumatically / hydraulically controlled setting of the saw blade feed Easy miter cutting positioning with fixed stop Easy stroke adjustment of the saw unit via 2 clamping levers Well dimensioned worm gear unit with EISELE shock-absorbing feature Quick and easy blade change

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

The dynamic way of sawing The HBE Dynamic series brings many features, which make your production even more profitable: — Solid and durable construction made of vibration damping grey cast iron — Sensitive BEHRINGER downfeed control system — Precise guiding system in portal design — Energy-efficient drive system — Excellent accessibility — Electrically driven chip brush, synchronized with blade speed — Easy operation by intuitive NC control system Different models based on cutting range ( 90° flat / 90° round): — HBE261A Dynamic: 300 x 260 mm / 260 mm — HBE321A Dynamic: 350 x 320 mm / 320 mm — HBE411A Dynamic: 510 x 410 mm / 410 mm — HBE511A Dynamic: 510 x 510 mm / 510 mm

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

To address the most stringent demands in terms of cutting output, high precision, automation and process reliability BEHRINGER HBM series high-performance automatic bandsawing machines offer an impressive package of benefits, guaranteed not only by their vibration-damping structure made of grey cast iron components and the saw frame with its centric flow of forces. The sensitive BEHRINGER feed control also helps protect the saw blade, ensuring even greater economy through a long tool service life. By using a servo feed system, a high cutting performance is achieved when sawing tool and stainless steels and materials such as Hastelloy or Inconel with difficult machining properties. A highly efficient chip brush system cleans the saw blade on both sides from any adhering sawing chips.

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

In forging mills, rolling and gravity die-casting foundries, and steel finishing works, these machines provide the ideal answer for dealing with large dimensions. They are perfect for preproduction in tool and mold making factories, helping to save valuable milling time. The material support table is recessed in the foundation. Its low-level transition to the hall floor makes for simpler material handling. The moving saw frame can be positioned by axis control precisely at the point of cutting. Where no sawing is taking place, the table is freely accessible. This also allows space for a second piece of material to be loaded while the saw is cutting. This system helps reduce downtime between cuts and enhances productivity. Benefits of the Gantry Machines - Space-saving installation - Durable material support table - Simple positioning of the saw frame - Optional: blade guide with 90° rotation facility for vertical and horizontal sawing to allow notching of materials

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

Their flexibility and high performance make BEHRINGER tabletop machines the ideal solution for the medium ton range. The table moves the weight BEHRINGER tabletop machines are ideal for use in forges, rolling mills and die casting factories, in steel finishing works and for tool and mold making. Their individually traversable material clamping vices and blade guide arms make these ideal for cutting bulky materials. The low table height makes this type of machine ideally suited for use on normal hall floor level. BEHRINGER tabletop machines are supplied as standard in semi-automatic form. Automation is possible by upgrading with an additional material clamping vice at the end of the table. Positioning takes place on an axiscontrolled basis. Optionally available is 90° rotatable blade guide for vertical and horizontal sawing to allow notching of materials.

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

The new HBE Performance Series offers high performance, with ease of use and efficiency. An increase in performance while reducing power consumption, combined with a small footprint, increased health and safety aspects and still provide easy handling were just some of the demands within its development. The HBE Performance series brings many features, which make your production even more profitable: — A solid and durable design made of vibration dampening grey cast iron — Outstanding cutting performance by Servo-Downfeed system with Auto-Feed-Control — Excellent blade life due to the sensitive BEHRINGER downfeed control system, inclined band wheels and effective chip disposal — Easy operation by intuitive NC control system Different models based on cutting range ( 90° flat / 90° round): — HBE560A Performance: 560 x 560 mm / 560 mm — HBE663A Performance: 710 x 660 mm / 660 mm — HBE860A Performance: 860 x 860 mm / 860 mm — HBE1060A Performance: 1.060 x 1.060 mm / 1.060 mm

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

Full power in any position The universal machines from BEHRINGER can handle any job that is needed. Perfect to slicing through sectional steel as well as solids in metal and comparable plastics at almost any optional angle. With precise cuts, individually adjustable for bidirectional mitre cuts between 90° and 45°, and optionally even for acute angles of 30°. Semi-automatic variants In the BEHRINGER semi-automatic models, the material is positioned by eye, for instance with the aid of a linelaser. This procedure is recommended for frequently changing cut-off length and when the sections are marked on the material already. Automation Where larger cut-off lengths are required, we recommend the use of a measurement device for precise positioning of the material. Used in conjunction with infeed and outfeed peripheral devices such as roller conveyors and transverse transport devices, the degree of automation can be increased to achieve added streamlining effects.

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

The LPS-T 3D has been developed for cutting 3D-Printing Plates in different sizes up to 850 x 650 mm. Highest precision ensures optimal cutting results and guarantees, that neither the printplate nor the printed parts get damaged. The result is, that the height of the supporting structure of the printed parts can be reduced. The individual fabrication of the bolted plates provides high flexibility for sawing 3D-Printing Plates in different sizes and shapes. The Stop-System with alignment on the printplate simplifies the set-up mode and reduces sources of errors. Both, the table and the fixture are moveable, which ensures an easy loading and handling. To adapt the sawing system to the process in an optimal way, BEHRINGER offers various options such as machine cover with suction device, spray mist system and individual clamping devices.

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

The SLB bandsawing machines from BEHRINGER: A trustworthy partner for workshop and plants. Suitable for cutting tubes, profiles and solid materials made of metal and comparable plastics. Competitive pricing, precision made components, and impressive power. See for yourself. - Mitre cuts are possible from + 30° to – 45° - Scale for setting the exact angle — Clamping of the saw frame with a quickly-tension lever — Downfeed control by a hydraulic flow control valve - Automatic height-setting of the saw frame above the material — Frequency controlled sawblade drive (optional) — Exact cutting

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

The HBE320-523 3D has been developed for cutting 3D-Printing Plates in different sizes up to 500 x 300 mm. Highest precision ensures optimal cutting results and guarantees, that neither the printplate nor the printed parts get damaged. The result is, that the height of the supporting structure of the printed parts can be reduced. The individual fabrication of the bolted plates provides high flexibility for sawing 3D-Printing Plates in different sizes and shapes. The Stop-System with alignment on the printplate simplifies the set-up mode and reduces sources of errors. The fixture ismoveable, which ensures an easy loading and handling. To adapt the sawing system to the process in an optimal way, BEHRINGER offers various options such as machine cover with suction device, spray mist system and individual clamping devices.

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

Integrated into the machine base is the coolant system or, -as option- the microspraying system. The design of the base made of thick steel plate leads to reduced vibrations during cutting. A chip drawer makes the disposal of the chips so easy. Manually operated machines offer a smooth and easy sawblade feed via their lever, gearwheel and toothes rack. The semi-automatically operated machines offer a variable, hydro-pneumatically controlled setting of the sawblade feed. Each mitring position can be set with ease and accuracy within a range of 45°-90°-45-30°. The upper part of the sawing machine is swivelled into mitring position, lefthand up to 45°-righthand up to 30°. The jaw is moved easily from left to right. The material remains in its position. hardened and ground gear wheels and wormgears are the assurances for the longevity combined with highly reduced vibration adding to the sawblade lifetime.

Request for a quoteResults for

Sawings - Import exportNumber of results

35 ProductsCompany type