- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- rotors

Results for

Rotors - Import export

MECHASYS GMBH

Germany

Electrical Steel: rotor and stator sheets as full service Due to the growing demand for electrical steel, we have bundled our technological resources and expanded the production of pure sheet metal blanks to complete packages in stator and rotor sheets. We are therefore able to provide you, our customers the service of complete sheet metal stacks baked, laser-welded or punched packaged in the electrical steel sector. Due to our extremely thin cutting gap of just 0.07mm - as much as the diameter of a human hair - we are able to produce the smallest contours. The extreme power density at a max. laser power of 1,000 watts enable electrical sheets based on baked varnish technology with the lowest possible edge zone melting - burr-free. Everything 100% "Made in Germany" in packaged quality - usually tolerance class T7. Usual delivery times are approx. one week for cutted sheets, 2-3 weeks for baking or welding parts. Let’s get in contact for your new e-drive, rotor or stator!

Request for a quote

PRESSTECK S.P.A.

Germany

For our customers in the automotive and housing industry, we produce deep-drawn stainless steel pots with an integrated axle as a monobloc component. These are used in water pumps for electric vehicles. Our customer from the automotive industry needs pots with an integrated axle that holds a rotor. Up to now, the pot and axle have been joined in a centred manner by means of welding. The customer's wish was to produce a one-piece component to avoid welding. Deep drawing is the ideal technology for this. The size of the component required larger presses than were previously available. Therefore, we first developed tools as prototypes for larger presses on behalf of the customer. After practical tests at the customer's premises as well as at the end customer's, our client decided on a tool that was ideally suited for the production of the component in series.

Request for a quote

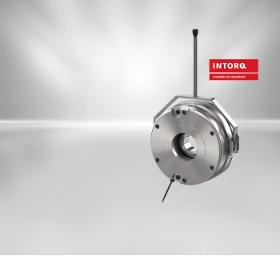

KENDRION (VILLINGEN) GMBH

Germany

When operating in crane and port facilities, a braking system must primarily be reliably protected and, secondly, must operate very powerfully. The INTORQ BFK 471 product series combines these two features perfectly. These specially sealed brakes have a newly designed hand-release mechanism which, like the brakes themselves, is IP66 compliant. This series also features high braking torque and requires only a compact installation space.

Request for a quote

YSTRAL GMBH MASCHINENBAU + PROCESSTECHNIK

Germany

The YSTRAL high-performance dispersing machines work according to the rotor-stator principle with high shear gradients. The extreme fine distribution of solids (suspensions) and liquids (emulsions) in presented liquid media is achieved by the perfectly coordinated interaction of various comminution processes. The high-precision dispersion tools are individually adapted to the respective task. Robust rotor-stator tools with a narrow radial gap ensure high shear gradients. A strong dispersing effect is achieved by impact and high-frequency pressure-relief processes. Solid particles and/or droplets are reliably comminuted and homogeneously distributed. Different rotor-stator-pairs allow the adaptation to the corresponding application. No rotating vessel contents - no formation of droplets and no air ingress. No free-running shaft and no free-running dispersing tools. Batch dispersion directly in the vessel.

Request for a quote

YSTRAL GMBH MASCHINENBAU + PROCESSTECHNIK

Germany

The YSTRAL inline dispersing machines work according to the rotor-stator system. The dispersing machine is suitable for the production of suspensions, solutions and emulsions in the chemical, food, pharmaceutical and cosmetic industries. Due to the close radial gap between rotor and stator and the high circumferential speed of the rotating rotor, very large shear gradients are generated. The product enters the shear zone through the slots between the rotor teeth and leaves it again via the stator slots. Due to the multi-tooth configuration of rotor and stator, additional mechanical forces act on the product to be dispersed. The product is guided through a rotor-stator system. The liquid is highly accelerated by the inner rotor ring, is completely decelerated at the stator ring and then accelerated again to maximum speed via the next rotor ring. In this way, solid particles and/or droplets are effectively comminuted and homogeneously distributed.

Request for a quote

YSTRAL GMBH MASCHINENBAU + PROCESSTECHNIK

Germany

The YSTRAL jet stream mixer fulfils all requirements for a complete and homogeneous mixing of the contents of a vessel. Effective micro- and macro-mixing of the entire contents of the vessel without the introduction of air. Complete mass transfer across all vessel levels due to vertical mixing. Up to 90% of the energy used is converted into vertical flow - no rotating vessel contents. Even heavy sediments are suspended by directed streams. Rotating parts are protected against unintentional intervention. With open tanks no tank fixing is necessary. A fast rotating rotor surrounded by a stator generates a downward directed guide jet which directs the liquid flow directly to the bottom of the container. At the bottom of the container, the stream splits and creates an upward flow on the outer wall. At the surface, the liquid flow is redirected towards the bottom of the tank.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Rotors - Import exportNumber of results

6 ProductsCompany type