- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- processing technology

Results for

Processing technology - Import export

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

Lipp systems are modular and can be extended, modified or integrated into existing systems WITH EASE. Biogas plants from Lipp are based on the so called, wet fermentation. Through a 2 stage process, i.e., via regulation by an upstream hydrolysis stage or other substrate pre treatment, input materials are prepared so that the anaerobic process can run optimally in the digester. Since it is the most flexible and the biological processes are best kept controllable Lipp favours the SBR process. This is also particularly suitable for anaerobic wastewater treatment, sludge digestion and is also used in agricultural biogas deposits. This means first that Lipp biogas plants are substrate flexible and allow an intensive use of the available digester area. Secondly, that with low self sustaining energy requirements, a high degradation rate is achieved. It is interesting to note that Lipp’s digester can be operated not just in the SBR process (Sequence Batch Reactor).

Request for a quote

GEBR. HELLER MASCHINENFABRIK GMBH

Germany

Flexible production of crankshafts and camshafts Machine series for perfect internal and external milling - as stand-alone machine or linked manufacturing system Highlights Internal and external milling of crankshafts Turn-chasing of crankshafts External milling of camshafts Advantages Unique HELLER know-how of the complete process chain Use of a combination of different technologies Dependable process control

Request for a quote

CIC - KLAUS CZERWONKA

Germany

Special cylinders developed and manufactured according to individual customer requirements, specifications or specifications. Both as a completely custom-made special cylinder or modified inexpensively using standard elements with adjustments in form, function, mount, connection or material.

Request for a quote

BIZERBA SE & CO. KG

Germany

Designed for integration in a control cabinet on top hat rail The weighing module WM-3 can be comfortably programmed using a PC tool. Data can be output to SPS, PLS, or ERP systems easily using the ports. The large number of ports ensures comprehensive system integration. Area of Use For weight recording, data output and control in logistics, in warehouse and process technology or for fill level checks Highlights Conception for the control cabinet System integration with high process security Programming via PC tool Multiple port options Product images and technical information could deviate and may not be available in your country.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

WASTE TO ENERGY INDUSTRY BIOGAS FROM ANAEROBIC WASTE WATER TREATMENT AND WASTE FERMENTATION PLANTS. Due to their technical characteristics and profitability, Lipp tank and system solutions are used in a variety of industrial biogas plants. Two areas of application can be distinguished, which in many cases also follow both objectives. APPROPRIATE PROCESS TECHNOLOGY, SUITABLE CONTAINER TECHNOLOGY AND THE RIGHT DIMENSIONSFirst, the anaerobic treatment of various industrial waste waters, such as in food production, biofuels or similar. The main objective here is the anaerobic pretreatment of highly contaminated but easily degradable waste water to reduce the COD load before it can go to the next stage of aerobic waste water treatment. The challenge is that in spite of the low DM content, a high degree of degradation is achieved by biomass retention or return and at the same time, biogas is produced. Due to the flexibility and variability of the Lipp system in terms of procedures

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SCHOCK GROUP

Germany

SCHOCK’s core competencies include roll forming technology with a large number of integrated processes. With our roll forming technology we are able to produce individual and high-precision profiles or complete assemblies for our customers.

Request for a quote

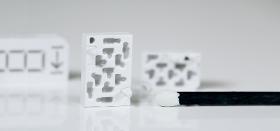

KUNSTSTOFFTECHNIK SCHMID GMBH & CO. KG

Germany

Customers from a wide range of industries rely on technically sophisticated injection-moulded parts made with up to three components. Our unique strength lies in the areas of multi-component technology, thermoplastics processing, elastomers and high-performance plastics.

Request for a quote

EMAG ELDEC INDUCTION GMBH

Germany

ECO LINE HF generators: Robust technology — efficient heating processes ECO LINE series high-frequency generators are a great match for virtually any production solution. They provide a continuous power of 5 to 75 kW. HF generators with many optional features A combination of advanced power electronics, state-of-the-art control technology, and strict selection processes for all components delivers a top-of-the-line, high-frequency generator usable either as a standalone solution or integrated into a larger system. In either case, users benefit from a technology that offers extremely precise energy dosing for improved consistency and repeatability in production processes. Another strength is the large variety of ECO LINE HF generators, with power ratings from 5 to 150 kW, frequencies from 60 to 400 kHz, multiple outputs and flexible options for control.

Request for a quote

ANDREAS MAIER GMBH & CO. KG (AMF)

Germany

Wireless seonsoring systems from AMF: flexible, compact and economical. They enable fully automated production processes for clamping technology as well as for modern handling and storage systems. The system consists of sensors and transmitter units that are interlinked both with the gateway and recipient, which communicates wirelessly with the machine control by means of Bluetooth Low Energy.

Request for a quote

BRÜCKNER TEXTILE TECHNOLOGIES GMBH & CO. KG

Germany

In the field of minimum application unit we can offer different application units such like floating knife, mini kissroll, knifeoverroll and screen or predosed kissroll units. These units offer the following advantages compared to a traditional padder process Lowaddon technology with a fabric moisture of 60 g/sqm, lower water consumption and thus high energy savings during the subsequent drying processes, low residual liquor (2.5 litres per metre working width) and thus fewer chemicals which have tob e disposed of during a batch change. Test can be carried out at any time on our test plant in our Technology Centre in Germany.

Request for a quote

OPTIMA CONSUMER GMBH

Germany

Containers: - Container or cap feed as bulk goods via fully automatic sorting and optional storage bin - Raising the container when filling to prevent dust accumulation - Centering the container for the optimal positioning of the containers below the work stations - Cycled container transport - Very gentle processing of the containers and packaging - Processing different container shapes Manufacture/Closing: - Simple integration into existing packaging technologies - Process-reliable sealing using thermal sealing, induction or ultrasound is possible - Processing all standard types of caps

ARNOLD UMFORMTECHNIK GMBH & CO. KG

Germany

The future is lightweight – with Flexweld®. Flexweld®, the unique joining process, offers countless benefits, with one of the biggest advantages being the considerable weight reduction in the age of lightweight construction. Moreover, no additional machinery is required to incorporate it into an existing car body assembly line. significant weight saving, which provides long-term reduction in CO2 emissions joins lightweight materials to high-strength metals can be incorporated into existing assembly lines since it is possible to use the same production and welding equipment no additional qualification for workers needed complete system including full feeder and processing technology mixed production possible by adapting the spot weld gun software

Request for a quoteResults for

Processing technology - Import exportNumber of results

13 ProductsCompany type

Category

- Tanks, metal (2)

- Sensors (1)

- Automation - systems and equipment (1)

- Cutting - steels and metals (1)

- Electricity - production and distribution (1)

- Mechanical transmission - components (1)

- Packing and packaging - machinery and equipment (1)

- Technical textiles for industrial applications (1)

- Vehicles - mechanical components and parts (1)

- Weighing and dosing equipment (1)