- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- processing of stainless steel

Results for

Processing of stainless steel - Import export

PRESSTECK S.P.A.

Germany

Experts for deep-drawn parts made of stainless steel, aluminium and other non-ferrous metals (including brass, copper and nickel silver).from new development to series production: We develop perfect deep-drawn parts. Pressteck is one of the world's leading specialists for deep drawing individual parts on transfer presses and for their further processing into assemblies. In this non-cutting forming process, we produce hollow parts in several stages from a metal strip that can be made of aluminium, stainless steel, copper or brass, among other materials. Deep drawing has decisive advantages over other processes: Material consumption and production costs are lower, and at the same time the strength of the components is higher. We are highly innovative and perfect deep-drawing technology beyond what has been possible so far.

Request for a quote

FLUX-GERÄTE GMBH

Germany

The VISCOFLUX mobile S drum emptying system was specifically designed for use in pharmaceutical, food and cosmetics industries. It is perfectly suited for ensuring efficiency and process safety while pumping high viscosity, paste-like, non-self-flowing media out of diverse drums – either with or without aseptic bags. Media can be transferred low-shear and continously. The residual amount remaining in the drum is up to less than 1 %. The mobile drum emptying system offers a high degree of flexibility and can also be operated in wet or damp production environments. The system's stainless steel process device bears the protection class IP 66.

Request for a quote

RUDOLF GUTBROD GMBH

Germany

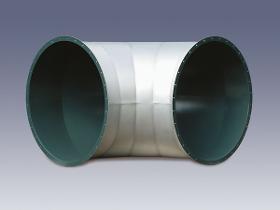

For the best only the highest quality ICS-ETFE is used for coating stainless steel process and utility pipework, for example. As a special, flame-resistant interior coating, this is particularily suitable for the coating of exhaust air pipework, for example, in factories in the chip, solar cell and fibre optics industries. ICS is FM-approved – each construction part is marked separately with the FM specification. This coating is also tested according to the American safety standard Factory Mutual Research 4910 and suitable for use in clean rooms. The coatings are used, amongst other things, in the chemical industry, the electrical industry, the automobile industry as well as in the food industry and in semiconductor technology. ETFE coatings are particularly well suited for use in the semiconductor and pharmaceutical industry. ETFE resists the most extreme conditions, such as e.g. the processing of high-purity grade water (molecules can still be extracted by this even from...

Request for a quote

RUDOLF GUTBROD GMBH

Germany

Special and flame retardant Just like ICS, ICS-ETFE is also suitable for coating stainless steel process and utility pipework, for example. As a special, flame-resistant interior coating, this is particularily suitable for the coating of exhaust air pipework, for example, in factories in the chip, solar cell and fibre optics industries. ICS is FM-approved - each construction part is marked separately with the FM specification. This coating is also tested according to the American safety standard Factory Mutual Research 4910 and suitable for use in clean rooms.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

TANK AND SYSTEM SOLUTIONS FOR WASTE WATER TREATMENT PLANTS Individual, customised container and system solutions have been one of the core business areas of Lipp GmbH for decades. This is demonstrated by the long list of references for completed tanks and equipment that have been implemented in close cooperation with well known engineering firms and companies for industrial waste water treatment plants at home and abroad. From simple, open topped waste water tanks through process vessels with special requirements for stainless steel and sealing materials to fully equipped fermenter types, (SBR, CSTR etc.) for different applications, Lipp offers a wide range of system solutions. Each project is planned and manufactured individually according to specific customer requirements for material, diameter, process instructions etc., and installed and tested if necessary in close cooperation with the partners. The versatility of the Lipp system in combination with process

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BOLZ PROCESS TECHNOLOGY GMBH

Germany

Gypsum Design - Series V 800 - 1600 BG Through many years of experience with renowned plant manufacturers in the area of flue gas desulphurization (FGD) plants, HEINKEL is in a position to ensure smooth, reliable project handling on schedule. Worldwide plaster from flue gas desulphurisation plants is dewatered in power plants using HEINKEL centrifuges. The broad range of plaster centrifuges with different basket sizes allows for optimum adaptation to changing product properties and throughputs. Special properties for the customer´s benefit: Optimum application for small to medium throughputs High availability Minimum residual moisture Maximum reduction of chloride concentrations through optimised washing process Alternatively stainless steel or rubber coated

Request for a quote

MSE FILTERPRESSEN GMBH

Germany

MSE stainless steel filter presses comply with the high hygiene and purity standards both in design and processing. With the stainless steel filter press, all components in contact with the product are covered with high-quality stainless steel. This also provides optimum protection against corrosion. FDA-COMPLIANT SOLID-LIQUID SEPARATION WITH THE MSE STAINLESS STEEL FILTER PRESS A large number of materials with different properties are used in the food sector in particular. Here, especially care must be taken to ensure that no ingredients are released into the food. The law stipulates a FDA certification for this. Accordingly, all materials used must be FDA-certified. The FDA certification stands for high purity and durability. Each component such as the filter plates, filter cloths and piping systems complies with the FDA guidelines. This contributes to high hygiene and safety requirements.

Request for a quote

LIQUOSYSTEMS GMBH

Germany

Plate heat exchangers are a part of the wort cooling in the beer production process. Made of stainless steel. The heat exchangers are vacuum-hard wired. They must be made of stainless steel plates and copper solder, which are looking at stainless steel.

Request for a quote

ASSFALG GMBH

Germany

The KKF4-SL, a universal chamfering and contour milling machine, has an ER collet chuck. Tools with a shaft diameter from Ø6-12 mm can be clamped. Our versatile tool range includes different VHM milling cutters and blade heads. The VHM milling cutters are available for the processing of chamfer angles and radii. Ball bearings with Ø6 or Ø8mm are used for contour processing with the VHM milling cutters. Tapered contour chamfers are used in combination with guide fingers or stop rulers. The use of cutter heads with cutting inserts and guide ball bearings starting at Ø10mm permit maximum efficiency. A guide prism with VHM shaft chamfering can be used for straight edges. The exact chamfer setting is performed through a micrometer screw. A chamfer width of up to 4mm at 45° is possible in steel. In NE metals, significantly larger chamfers are possible depending on the tool and angle. The KKF4-SL has speed regulation that is very useful for the processing of aluminum or stainless steel.

Request for a quote

ASSFALG GMBH

Germany

The sturdy chamfering machines are designed for chamfering, edge chamfering and welding seam preparation. The machines can process sheet thicknesses from 2-190mm. The machines generate a very good chamfering quality thanks to the optimized interaction between the cutter head, cutting inserts and minimal quantities of lubrication. In NE metals and steel, a chamfer width up to 30mm is possible. The MMB machines have gradual speed regulation, which is very useful when processing aluminum or stainless steel. The angle adjustment can be set gradually in the range of 30° depending on the machine type and design, for example, 25-55°, 30°-60° or 35-65°. The MMB series is equipped with a feed unit by default. The machines can be extended with roller guide ways or converted into automatic chamfering machines. Depending on the design, the machine table is equipped with ball or heavy-duty rollers.

Request for a quote

ASSFALG GMBH

Germany

The sturdy and easy chamfering machine is designed for deburring and chamfering of small to large workpieces from 1 mm thickness. The machine generates a perfect chamfering quality thanks to the optimized interaction between the cutter head and cutting inserts - like sanded. In NE metals and steel, a chamfer width up to 10mm is possible. The ASO160-M is ideal for processing steel and aluminum. The ASO 160-MSL design has speed regulation that is very useful for the processing of aluminum or stainless steel. For longer workpieces or serial part production, we recommend optimizing the feed unit with pressing pressure, surface quality, feed speed and service life of tools. The machine can be installed on an undercarriage for flexible use in a workshop, which simultaneously serves as a chip box.

Request for a quote

ASSFALG GMBH

Germany

The sturdy and easy chamfering machine is designed for deburring and chamfering of small to large workpieces from 5 mm thickness. The hardened and sanded guide rails must be turned for smaller and thinner workpieces starting with a thickness of 2 mm. Thanks to the optimised interplay of cutter head and cutting inserts, the machine ensures clean and constant chamfering. A chamfer width of up to 12 mm is possible in NE metals and a chamfer width of up to 10mm in steel. The cutting edge length of the cutting inserts can be used 100% thanks to the innovative axially adjustable motor shaft. The ASO 650-WSL has speed regulation that is very useful when processing aluminum or stainless steel and a gradual angle adjustment in a range from 15-45°. A radius processing from R1.2 to R6 is possible with different cutting inserts. For longer workpieces or serial part production, we recommend optimizing the feed unit with pressing pressure, surface quality, feed speed and service life of tools.

Request for a quote

ASSFALG GMBH

Germany

The SMA 40-A series is available in an electrical or compressed-air operated design. The machine is designed for handling steel, aluminum, copper and plastics. A chamfer width of up to 16 mm is possible in NE metals and a chamfer width of up to 12mm in steel. In addition to this, a radius processing of 1.2mm to 8mm is feasible. The stunning and patented 8 or 16 cutting turning plate system guarantees long service life, best surface qualities and efficient working. The electrical design of the SMA 40 is equipped with a speed control and should be preferably used for stainless steel processing. The cutter heads are available for chamfer angles between 0 - 80°. The processing of drill holes is already possible starting at a diameter of >28mm. For tight contours, long holes and bores, a single-cutting cutter head with a fitting guide roller is available, Ø10mm to Ø20mm depending on application.

Request for a quote

ASSFALG GMBH

Germany

The SMA 30-A series is available in an electrical or compressed-air operated design. The machine is designed for handling steel, aluminum, copper and plastics. A chamfer width of up to 8 mm is possible in NE metals and a chamfer width of up to 6mm in steel. In addition to this, a radius processing of 1.2mm to 6mm is feasible. The stunning and patented 8 or 16 cutting turning plate system guarantees long service life, best surface qualities and efficient working. The electrical design of the SMA 30 is equipped with a speed control and should be preferably used for stainless steel processing. The cutter heads are available for chamfer angles 30°, 45° and 60°. The processing of drill holes is already possible starting at a diameter of >28mm. For tight contours, long holes and bores, a single-cutting cutter head with a fitting guide roller is available, Ø10mm to Ø20mm depending on application.

Request for a quote

ASSFALG GMBH

Germany

The sturdy and easy-to-use chamfering machine was designed for the deburring and chamfering of small to medium-sized workpieces and bar material starting with a thickness of 1 mm. The machine generates a very good chamfering quality thanks to the optimized interaction between the cutter head and cutting inserts. In NE metals and steel, a chamfer width up to 11mm is possible. The WKF 170 has gradual speed regulation, which is very useful when processing aluminum or stainless steel. The angle adjustment can cover a range from 15-60° in 5° steps. For longer workpieces or serial part production, we recommend optimizing the feed unit with pressing pressure, surface quality, feed speed and service life of tools. The machine can be installed on an undercarriage for flexible use in a workshop, which simultaneously serves as a chip box. The machine can be extended with roller guide ways or converted into an automatic chamfering machine.

Request for a quoteResults for

Processing of stainless steel - Import exportNumber of results

16 ProductsCompany type