- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- process automation

Results for

Process automation - Import export

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

LIPP® Welded Tanks offer the ideal storage solution for a wide variety of media. Tanks are produced by means of an automated welding process specially developed by LIPP® and can be constructed individually in diameter in volumes of 50 to 10,000 m³ according to the application. LIPP® offers a corresponding selection of metallic materials suitable for use with storage media ranging from drinking water and foodstuffs to ethanol or oil. These materials range from a variety of different steel grades to highalloy stainless steels. The automated process meets the highest quality standards. LIPP® Welded Storage Tanks can be produced within a short time, either on site in the open air or inside a building.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

LIPP drinking water tanks for water supply companies are offered together with our project partner Kurz Leitungsbau GmbH. In doing so, we meet the highest standards applicable to the supply of drinking water, from planning and conception up to construction. Our automated welding process for high alloy stainless steels based on the LIPP System enables us to offer tanks with a maximum volume of 10,000 m3. In addition, on site production “off the production line” enables construction to be completed within the shortest possible time. Optimum quality thanks to automated welding process Material savings and additional stability thanks to circumferential profile Short construction times thanks to mechanised production Easy to maintain and clean Low investment and maintenance costs Can be set up indoors or in the open air Turnkey complete solution or components

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

IN STEEL AND STAINLESS STEEL FROM 50 – 10,000 M3 LIPP welded storage tanks offer the ideal storage solution for a wide variety of media. Tanks are produced by means of an automated welding process specially developed by LIPP and can be constructed with steplessly adjustable volumes of 50 to 10,000 m³ according to the application. LIPP offers a corresponding selection of metallic materials suitable for use with storage media ranging from drinking water and foodstuffs to ethanol or oil. These materials range from a variety of different steel grades to high alloy stainless steels. The automated process meets the highest quality standards. LIPP storage tanks can be produced within a very short time, either on site in the open air or inside a building. The special circumferential profile ensures additional stability compared to conventional processes. KEY BENEFITS Three different welding processes based on the LIPP system and adjusted to the application

Request for a quote

FESSMANN GMBH UND CO KG

Germany

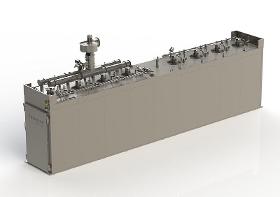

The semicontinuous TFi3000 for industrial use is not a compromise, but rather the combination of the benefits of two entirely different systems! It permits smoke, heat and cold treatments in a single production step. Automated work processes lower your operating costs while at the same time increasing production capacities. Efficient combination of Ti3000 & IKi3000 Production justintime, controllable and reproducible work processes Much lower germ formation and contamination – for longer durability Automatic transport system Producing, packaging and delivery in a very short time Lesser demand of cold storage capacities Higher trolley capacity as comparable floor conveyor systems by low construction

Request for a quote

FESSMANN GMBH UND CO KG

Germany

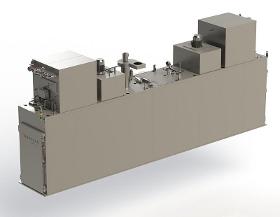

The TF3000 combines the Turbomat T3000 and the intensive cooling system IK3000 in a single closed system. This means one thing most of all Best output per chamber part for the shortest process times. The automated transport system not only reduces operating costs, but also increases production capacities in the system. Maximum output per chamber part Production justintime, controllable and reproducible processes Much lower germ formation and contamination – for longer durability Automatic transport system Producing, packaging and delivery in a very short time Lesser demand of cold storage capacities Higher trolley capacity as comparable floor conveyor systems by low construction

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

LESER GMBH

Germany

Flocked deep-drawing inlays for writing instrument packaging are produced in a highly automated process and individually adapted to your writing instruments!

Request for a quote

AERO-LIFT VAKUUMTECHNIK GMBH

Germany

Not only uneven, structured surfaces but also undefi ned pick-up positions and varying dimensions can be easily be handled with the aid of the VUSS vacuum gripper. Be it in logistics, small trade or industry. AERO-LIFT® VUSS facilitates the use of vacuum lifting equipment now for your materials – regardless of whether a pallet of cans is not full or there is a pile of wooden boards laying loosely together or every workpiece has an individu-al, different size. process automation with vacuum gripper more efficiency and flexibility Function and features structure vacuum gripper The basic principle is really simple: The robot attaches a vacuum plate to the product to be transported instead of grabbing it. In such cases, it does not matter whether the products have holes, are slanted...

Request for a quote

OSMO MEMBRANE SYSTEMS GMBH

Germany

Recovery of flexoprint dye Picture: printing dye (red); ultrafiltrate (orange); nanofiltration permeate (clear) Application: Conditioning and concentration of cardboard printing dyes (flexo print), e.g. paper bag manufacturing, corrugated board manufacturing. Conditioning of the rinse waters by ultrafiltration(UF): Recovery and recycling of dyes, separated by tonality Further conditioning of the permeate by nanofiltration(NF): Recovery of the rinse water Further conditioning of the UF-concentrate by evaporation / distillation as pre-stage for external disposal Advantages of the process: Recovery of dyes separated by tonality is possible and established Recirculation of the rinse water is possible and established Reduction of the waste water amount At existing waste water treatment plants (based on precipitation) amounts of sludge can be reduced enormously Compact and modular design Fully automized process - low personnel costs High degradation rate and efficiency (concerning CSB, Cu,

Request for a quote

ANDREAS MAIER GMBH & CO. KG (AMF)

Germany

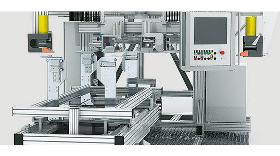

Wireless seonsoring systems from AMF: flexible, compact and economical. They enable fully automated production processes for clamping technology as well as for modern handling and storage systems. The system consists of sensors and transmitter units that are interlinked both with the gateway and recipient, which communicates wirelessly with the machine control by means of Bluetooth Low Energy.

Request for a quote

EMAG ELDEC INDUCTION GMBH

Germany

eldec brazing systems: automatic induction brazing of pole coils The semi-automatic equipment is designed for manufacturing pole coils of hydro and wind power generators. The machine is based on the experience of the previous manufactured equipments. The machine is designed as a sturdy, high quality and low maintenance machine. The operating is very simple, on automatic mode by 2-hand operation with step by step program and on manual mode by touch-panel.

Request for a quote

WIFERION - A PULS BRAND

Germany

As a system provider of charging and storage technology, we are presenting our inductive fast charging system etaLINK 12000 for the first time on these pages. The solution enables in-process charging of the lithium-ion batteries of driverless transport systems (AGVs / AGVs), industrial trucks (FFZ) and mobile robots. Loading processes can be flexibly integrated into the intralogistic processes. The scalable energy solution is the world’s first contactless battery charging system with an output of 12 kW and an efficiency of 93%. The result is fully automated charging processes and vehicle availability increased by up to 30%.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

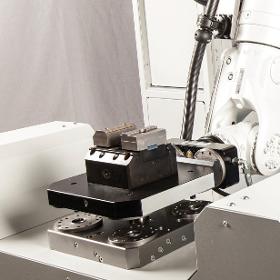

You are short of personnel, but have to process your orders, preferably 24/7? Then the DockLock AC zero-point clamping system for automated fixture change-over, in either the hydraulic or pneumatic version, is perfect for you. The clamping device quick change-over system for stationary applications allows automated change-over of your clamping devices in two minutes. And with repeatability of ≤ 0.005 mm, without alignment. The design of the form fit clamping and power transmission is identical to the DockLock for manual set-up. In addition, it is equipped with a closure at the clamping position as protection against contamination and chips. That ensures even less wear and reduces maintenance expenses. In addition, standard features include an air sensing control, air-blast support isles and a piston position control for a safe and reliable automated process.

Request for a quote

ARNOLD UMFORMTECHNIK GMBH & CO. KG

Germany

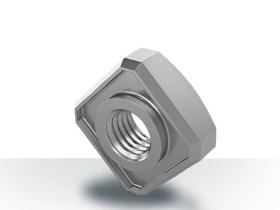

With PIAS® pierce-clinch nuts (square) and RIVTEX® (ROUND) a non-detachable metal fastening can be created at optimum cost. The pierce-clinching technology is suitable for steel and aluminium sheets, causes very little cost for inspection and control, and allows several pierce-clinch screws to be processed in a single stroke. PIAS® and RIVTEX® pierce-clinch nuts offer the following advantages over welded nuts: corrosion-resistant no weld spatter on the thread no thermal weakening at the fastening position self-piercing higher torque requirements high process reliability in fully-automated processing flush-mounted processing processing can be manual, semi or fully automated self-locking thread possible

Request for a quoteResults for

Process automation - Import exportNumber of results

14 ProductsCompany type

Category

- Tanks, metal (2)

- Cooking and smoke-curing equipment for delicatessens (2)

- Automation - systems and equipment (1)

- Storage tanks (1)

- Battery chargers (1)

- Custom packaging (1)

- Induction heating systems (1)

- Machine tools, metal machining - parts and accessories (1)

- Measurement and control instruments (1)

- Mechanical transmission - components (1)