- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- precision optics

Results for

Precision optics - Import export

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

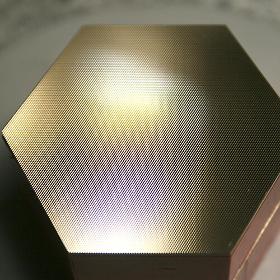

With the chip-removing microstructuring of metal surfaces, LT Ultra offers the right manufacturing technology for the production of embossing tools with optical surface qualities that allow economical replication in large numbers. Examples of microstructuring are the production of microfluidics or microlenses on our ultra-precise multi-axis machines. We can manufacture the structures directly in various materials such as brass, chemically deposited nickel or in selected hardened steels.For the replicating production of optical components, ultra-precise mold inserts made of steel are of particular interest due to their very long service life compared to other materials. In order to avoid the final polishing, which often leads to an undesirable change in shape or which is impossible due to a high structure density, LT Ultra offers ultrasound-assisted machining of steels with geometrically defined cutting edges made of monocrystalline diamond.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

In the basic version the MMC 5000 consists of a main X-axis featuring a linear air bearing (feed axis), a linear roller bearing Z-axis (infeed axis) and the milling spindle (air bearing) mounted on top of the Z-axis. The main application is face milling of optical and mechanical precision components. A Y-axis is available as an option. Another useful accessory is a second milling spindle, used perpendicular to the first one, thus allowing for the machining of two sides of a workpiece to perpendicularity in one setup. Accessories, like vacuum chucks, different milling spindles, touch probes for part thickness measurement, machine interferometers and other sensors for insitu measurement of workpiece shape and roughness, make the MMC 5000 machines an effective tool. In addition, various sensors are available for measuring of the workpiece geometry and surface quality during the manufacturing process.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

The MMC 600/900 is the basis for a series of machines that, via several accessories and options, can be fully customized to individual needs. In the basic version the machine consists of a main X-axis featuring a linear air bearing (feed axis), a linear roller bearing Z-axis (infeed axis) and the milling spindle (air bearing) mounted on top of the Z-axis. The main application is face milling of optical and mechanical precision components. Several accessories like a Y-axis, an A-axis and/or C-axis are available, thus expanding the range of machinable parts to microstructures, lenticular structures, spheres, polygons and so on. Accessories, like vacuum chucks, different milling spindles, touch probes for part thickness measurement and even machine interferometers for insitu measurement of workpiece shape, make the MMC 600 and 900 machines an effective tool. Besides further accessories, there is the possibility to make customized solutions, to adapt the machine to your needs.

Request for a quote

BRUKER OPTICS GMBH & CO. KG

Germany

The IFS 125HR is the ultimate instrument for the high resolution IR spectroscopy Outstanding results in your laboratory In absorption or emission mode, the IFS 125HR can resolve highly complex spectra into discrete lines for recognition and spectral assignment. Outstanding resolution across the entire spectrum Resolved linewidths of < 0.0009cm -1 Broad spectral range: from 5cm -1 in the far-IR to >50,000cm -1 in the UV Double-sided interferogram acquisition (option) Symmetric line shapes - due to high precision optics Easy range change - every experiment can access different sources and detectors without breaking vacuum. A total of 4 sources and 6 detectors can be accessed through each of two different sample compartments

Request for a quote

BRUKER OPTICS GMBH & CO. KG

Germany

TANGO has exactly what users require of an FT-NIR spectrometer suitable for industrial use: robustness, high precision and straightforward operator guidance. • Proven FT-NIR technology by Bruker • Easy-to-use touch screen operation • Automated background management • Robust and precise optics • Direct calibration transfer to and from all Bruker Optics FT-NIR spectrometers Fast measurements for high sample throughput, simultaneous evaluation of different components and an intuitive handling, without need for expertise training: TANGO simplifies the NIR analysis and therefore offers maximum security of the results. It delivers reliable results wherever highest demands are made on raw materials as well as intermediate and finished products and a rapid measurement at low cost must be ensured.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Precision optics - Import exportNumber of results

5 ProductsCompany type