- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- power packs

Results for

Power packs - Import export

SIKO GMBH

Germany

With a maximum nominal torque of 14 Nm, the new AG24 is a real power pack for format adjustment Easy mounting. Stainless steel hollow shafts up to max. Ø 20 mm. “Manual” traveling without control via micro-button. Brushless 160 W, 24 V DC motor with long service life. Integrated absolute position encoder on the output shaft. Integrated positioning controller. Integrated spring-operated brake (option). 2-line LCD for target and position value and operating keys. Integrated Industrial-Ethernet-Fieldbus. M12 component mounting technology. Manual emergency adjustment.

Request for a quoteSTÄHLE GMBH

Germany

Actuator for the actuation of the Engine Start/Stop button in vehicles. Stand-alone controller with buttons for position selection and external selection via potential free contacts. Positions: - Idle position - Ignition On / pre-glow / fuel cell pack power-up - Engine Start / stop Simple set-up with key pad. Temperature resistant actuator in fail-safe design with mechanical, spring-actuated return to idle position in power-less situation which turns the engine off by moving through the engine start/stop position.. The system can be expanded by the actuator SCX for actuation of the ignition key and special mounting devices. A special rocker switch adapter is available for the GM Corvette and similar switches. Other interfaces like field bus can be offered.

STÄHLE GMBH

Germany

Actuator for the ignition key in vehicles. Stand-alone controller with buttons for position selection and external selection via potential free contacts. Positions: - Ignition Off - Ignition On / pre-glow / fuel cell pack power-up - Starter on / Crank Simple set-up with key pad. Temperature resistant actuator in fail-safe design with mechanical, spring-actuated return to ignition off position in power-less situation. The system can be expanded by the actuator SPX for actuation of the engine start / stop button and special mounting devices. Special back pack adapter is available for operation in combination with the full – range column shifter in case of space restriction around the ignition key area.. Other interfaces like field bus can be offered.

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

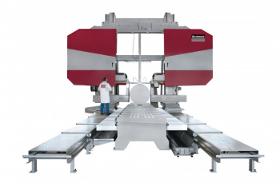

In forging mills, rolling and gravity die-casting foundries, and steel finishing works, these machines provide the ideal answer for dealing with large dimensions. They are perfect for preproduction in tool and mold making factories, helping to save valuable milling time. The material support table is recessed in the foundation. Its low-level transition to the hall floor makes for simpler material handling. The moving saw frame can be positioned by axis control precisely at the point of cutting. Where no sawing is taking place, the table is freely accessible. This also allows space for a second piece of material to be loaded while the saw is cutting. This system helps reduce downtime between cuts and enhances productivity. Benefits of the Gantry Machines - Space-saving installation - Durable material support table - Simple positioning of the saw frame - Optional: blade guide with 90° rotation facility for vertical and horizontal sawing to allow notching of materials

Request for a quote

KERSTEN ELEKTROSTATIK GMBH

Germany

The discharging generator DG 306 is the power pack of the KERSTEN next product family and can be used to supply all the next® discharging components. With its 6 high voltage connections he can easily manage every large installations, nevertheless it is very compact. With the patented DC High voltage technology you don´t have to worry about EMC interferences anymore while you receive the best possible discharge power. By using the 24 V DC fault indication contact, you have the option to receive a fault signal directly in your system. the High voltage Generator DG 306 is supplied by a 24 v DC input voltage and is therefore independent of the world´s different network standards. The generator provides two insulated and against reverse polarity secured high voltage connections, where discharging devices can be fast and easily connected to.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HPM TECHNOLOGIE GMBH

Germany

Small but powerful. Our power pack The smallest spray head available in the HPM standard range. Suitable for tight installation situations. The quantity is set on the back. The desired quantity can be reliably set using safety bolts. The supply line exits at an angle of 90° to the spray jet. Our PSM spray head is available in two variants: The PSMR spray head has an M5 thread for fastening to a customer-side mount. The PSMB spray head has a ball joint. This allows it to be attached flexibly and precisely with the flexible HPM Technologie mounts

Request for a quote

ULBRICH GMBH

Germany

Mobile Puller with 100 to press force with integrated acetylene-compressed air ring burner or high pressure hydraulic power pack. The solution with integrated acetylene-compressed air ring-burner is specially developped for wheel-disk without oil-pressure-drilling. While the solution with the high pressure-hydraulic power pack is put into action on wheel-disks with oil-pressure-drilling. It is also possible to have a puller with both solution combined.

ULBRICH GMBH

Germany

The lifting equipment consists of two mobile boogies. Integrated within the superstructure is a hydraulic power pack which drives the two hydraulic cylinders. The cylinders are situated in the highly robust and laterally adjustable lifting blocks. The lifting blocks and the jack contact surfaces (lifting points) can be repositioned along the cross-beam via a spindle. This allows the flexibility to lift and control a number of different types of Locomotive and carriage. Once the carriage has been lifted, the lifting blocks can be locked out using safety bolts which ensure that the height selected is safely maintained. The position of the safety bolts themselves can also be controlled by sensors. An optional function to weigh and calculate the centre of gravity is available upon request. Here, the lifting blocks have been fitted out with “load cells“, which can transfer the load input into a unit of weight. With the accompanying software these values can be evaluated in order to determi

Results for

Power packs - Import exportNumber of results

9 ProductsCompany type