- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pipe processing

Results for

Pipe processing - Import export

CIC - KLAUS CZERWONKA

Germany

CNC sheet metal processing, CNC laser parts, stamped parts, fine stamped parts, bent parts, pipe processing, cold forming, heat shielding sheets, deep-drawn parts, sheet metal parts from progressive dies, sheet metal parts assembled, sheet metal parts with surface treatment, sheet metal parts in large series, one-off production, prototypes.

Request for a quote

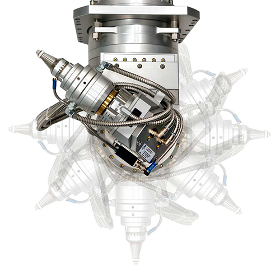

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

SD is our short cut for a laser head consisting of either the swivel axis only or in combination with a highly dynamic linear axis for laser processing of pipes. Suitable optics are used for the laser source used, either directly water-cooled metal mirrors with coatings of least absorption, or alternatively glass optics. The use of an adaptive optics optionally allows the freely programmable focus position for cutting and piercing. The exclusive use of torque motors reduces mechanically moving components and thus guarantees consistently high machining accuracy and best machining results over a long service life, against mechanical damage reliably protects our proven 3D collision protection. The clear aperture of the current laser swivel head SH35 is 35mm, the larger version SH60 is still available with a clear aperture of 60mm.

Request for a quote

ZINSER GMBH

Germany

ZINSER GmbH offers you top-class CNC cutting systems that impress with their outstanding quality, reliability and efficiency. Our systems include oxy-fuel, plasma and laser cutting technologies that are optimized for mild steel, stainless steel and aluminum. With customized solutions and innovative technology, our machines are ideal for demanding production requirements. Premium cutting systems 4000 series The ZINSER premium series (models 4025B, 4125B, 4026B, 4126B) stands worldwide for excellent cutting quality and machine reliability. These machines are perfect for oxy-fuel, plasma, laser, bevel cutting as well as drilling and threading. Economical cutting systems 2000 series Our economical models (ZINSER 2315, 2325, 2425, 2426) are powerful and robust. They offer precise cuts and high flexibility for various applications, including simple and bevel cuts and pipe processing.

Request for a quote

ZINSER GMBH

Germany

ZINSER GmbH offers advanced pipe cutting technology known for its precision and efficiency. Our systems are ideal for cutting cylindrical and polygonal pipes made of mild steel, stainless steel and aluminum. With the latest technology and high-quality materials, our machines ensure the highest cutting quality and reliability for industrial applications. ZINSER 1304 / 1306 These specialized pipe cutting machines offer precise and fast cuts. The ZINSER 1304 and 1306 models are perfect for processing pipes with complex geometries and different materials. They offer excellent results for breakthroughs, recesses and end processing. Advantages of ZINSER pipe cutting machines Highest precision: Exact and repeatable cuts thanks to the latest control technology. Versatility: Suitable for different pipe materials and diameters. Efficiency: Cost-effective cutting solutions thanks to innovative technology and robust construction. Durability

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

The HBP1100 - HBP1500 / HBP1100A - HBP1500A are series of semi-automatic and automatic large bandsaws manufactured by Behringer. The large-scale universal machines from BEHRINGER can handle any job that is needed. Their expertise: Handling heavy-duty workpieces with ease and slicing through the material with extreme cutting performance. When processing long solid workpieces – rolled or rough turned – or processing large pipes, these benefits make for dramatic improvements in productivity. Round or rectangular – the results are equally impressive. In the BEHRINGER semi-automatic models, the material is positioned by eye, for instance with the aid of a line laser. For longer cut piece lengths, we recommend using a measuring device for precise positioning. The use of a feed gripper allows automatic sawing of solid material or pipes.

Request for a quote

ASSFALG GMBH

Germany

With its placement prism on wheels, the ASO 760 is ideal for welded seam preparation for straight and large workpieces. Different welding chamfers can be produced through the angle setting from 0 - 60°. The two-disc chamfer with the wonderful and patented 8 cutting turning plate system guarantees long service life, best surface qualities and efficient working. The machine is designed for handling steel, aluminum, copper and plastics. A chamfer width of up to 18mm is possible here. Round materials or tubes starting with an external diameter of 150mm can be chamfered through an optionally available pipe chamfering device. Advantages: Processing chamfers on sheet metal, containers, outer edges Angle adjustment from 0 - 60° Up to 8-times usable turning cutting plates Sturdy and durable machine Good guide through two-hand operation Optional chamfering device starting at Ø150mm Controlled flying chips

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Pipe processing - Import exportNumber of results

6 ProductsCompany type