- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- packaging and packing

Results for

Packaging and packing - Import export

ALTMANN GRAPHISCHE MASCHINEN GMBH

Germany

max. size 36 x 49 cm age 2015 film packaging machine computer control with touch screen thickness up to 120 mm speed up to 28 m / min (offload) infeed belt without shrinking unit Delivery time: immediately from stock Ref: PA240044A Please ask for price. We ship and install worldwide!

Request for a quote

ALTMANN GRAPHISCHE MASCHINEN GMBH

Germany

age 2002 film packaging machine foil wrapping machine 1 main feeder opening station (vacuum and sword) 2 inserting station foil packing unit stream delivery Delivery time: immediately Ref: CM240148K Please ask for price. We ship and install worldwide!

Request for a quote

FLÖTER VERPACKUNGS-SERVICE GMBH

Germany

Packing and working table electrically height-adjustable Overhead unit light at the packing station With electric lifting axle for easy change of the roll at the overhead unit Mouse and keyboard tray Small rear wall board cardboard magazine Swiveling TFT arm signal lamp Holder for waste bin and tape dispenser AirWave1 Air Cushion Machine

Request for a quote

FLÖTER VERPACKUNGS-SERVICE GMBH

Germany

Packing and working table electrically height-adjustable Overhead unit light at the packing station With electric lifting axle for easy change of the roll at the overhead unit Mouse and keyboard tray Small rear wall board cardboard magazine Swiveling TFT arm signal lamp Holder for waste bin and tape dispenser AirWave2 Air Cushion Machine

Request for a quote

LIQUID-UNIVERSUM GMBH

Germany

full solution to bring the tax stemp/sign to the box or bottle

Request for a quote

LIQUID-UNIVERSUM GMBH

Germany

packaging machine for boxes for 1030ml bottles

Request for a quote

MOSCA GMBH

Germany

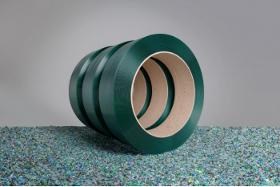

PET strapping is particularly tear-resistant and elastic at the same time. Thus they reliably absorb shocks during transportation and, depending on width, can sustain loads of between 185 and 580 kg. Our PET strapping is available in widths of 9.5 to 15.5 millimeters with tight fabrication tolerances. After use, it can be easily fed back into the material cycle, since it consists of 100 % recyclabled plastic bottles (bottle flakes). It has a high stability for optimal load security. Its constantly high quality ensures a high machine availability. Most frequent fields of application: • Corrugated cardboard industry • Printing industry • General logistics • Electrical industry (TVs, cooling/heating units, kitchen equipment) • Automotive industry (equipment and spare parts for cars, trucks and bikes)

Request for a quote

MOSCA GMBH

Germany

PP strapping represents approximately two-thirds of our production. We manufacture it as standard in widths 5-15 millimeters in black. On request, we will be happy to produce it for you in other colors as well. PP strapping material is particularly suitable for strapping packages, cartons or other containers, as well as lighter pallets. After use, it can be easily fed back into the material cycle. It is completely recyclable, has a constantly high quality, can be failure-free processed and is short-term available. Most frequent fields of application are: • General logistics (boxes of corrugated cardboard, styrofoam, plastic) • Printing industry (newspaper, magazines) • Corrugated cardboard industry (folding boxes, cut-outs) • Tins and bottles of plastic, aluminum and cardboard • Construction and container (furniture, wooden slats, tiles and bricks) • Food industry (meat, fish, poultry in folding boxes or styrofoam)

Request for a quote

MOSCA GMBH

Germany

Ultrasonic sealing system with electronic self-calibration Can be integrated into most production lines Flap frame with magnetic locking High-end Standard-6 sealing unit Horizontal sealing unit stroke (up to 340 mm) With strap lance for pallet strapping Automatic strap threading system Easy accessibility and tool-free disassembly of strap path components Dispenser variably mountable Adjustable strap tension via control panel Easy operation via digital display in the control panel Manual strapping release via push button in the control panel Stepless turnable control panel (0°-180°) for multisided operation CE marking incl. declaration of conformity Structural coating RAL 5010, gentian blue

Request for a quote

MOSCA GMBH

Germany

The space-saving models Saturn S2 and Saturn S4 are stretch wrapping machines featuring a rotary ring design where the load remains static while the film reels rotate around the load. • Medium performance: Up to 70 pallets / h • Guaranteed savings of stretch film: 300 % film pre-stretching; 1 m of film becomes 4 m • Finishes without tails of film due to our efficient cut and welding device • Electronic and self-adjusting tension control depending on the profile of the load • Capable of applying bands (strips) at any height of the load • Possibility of wrapping at ground level • Possibility of applying efficient dustproof and rainproof wrappings

Request for a quote

MOSCA GMBH

Germany

The fully automatic rotating ring stretch wrapper Saturn S8 is our fastest ring wrapper for maximum production processes. The film is attached around the load using a rotating ring while the load remains static. • Maximum performance: Up to 160 pallets / h • Guaranteed savings of stretch film: 300 % film pre-stretching; 1 m of film becomes 4 m • Finishes without tails of film due to our efficient cut and welding device • Electronic and self-adjusting tension control depending on the profile of the load • Capable of applying bands (strips) at any height of the load • Possibility of wrapping at ground level • Possibility of applying efficient dustproof and rainproof wrappings

Request for a quote

MOSCA GMBH

Germany

The versatile model Saturn S6 is our best-selling and most extensible rotary ring stretch wrapper. The film reel is mounted on the ring, which rotates concentrically to the load going up and down depending on the wrapping cycle, so the load remains static. • High performance: Up to 120 pallets / h • Guaranteed savings of stretch film: 300 % film pre-stretching; 1 m of film becomes 4 m • Finishes without tails of film due to our efficient cut and welding device • Electronic and self-adjusting tension control depending on the profile of the load • Capable of applying bands (strips) at any height of the load • Possibility of wrapping at ground level • Possibility of applying efficient dustproof and rainproof wrappings

Request for a quote

MOSCA GMBH

Germany

Inline strapping parallel to flute Thermostatically controlled heat-weld sealing Siemens PLC control with touch panel 5-sided electromechanical package alignment Potential-free contacts to upstream and downstream machines Automated setup system resets to the dimensions of the first bundle of the new size (“Teach-In”) Capability to strap up to 90 mm outside the bundle center (adjustment in steps of 10 or 30 mm) allows for perfect strapping of complex bundle sizes and forms Chassis on rails with mechanical locking [MCB-2 XT]: Two movable sealing units

Request for a quote

MOSCA GMBH

Germany

• Corrosion-resistant ultrasonic sealing system with electronic self-calibration • High-end Standard 6 sealing system • Easy accessibility and tool-free disassembly of strap way components • Wear-free DC drives with integrated electronics • Stepless turnable operation panel for many-sided operation • Adjustable strap tension via potentiometer • Switching from maximum to material-friendly Eco-speed in the control • Quick strap coil change • Strap coil changeable from the front and the side • Automatic strap threading system • Strap end detection with ejection of remaining strap • Automatic strap loop ejection • Extremely low energy consumption • 4 castors, 2 of them lockable (Ø 80 mm) • CE marking inclusive conformity declaration • Soft strapping selectable for sensitive packages • Machine completely corrosion-resistant (main use of V4A stainless steel) • IP 56 protection class design

Request for a quote

MOSCA GMBH

Germany

Ultrasonic sealing system with electronic self-calibration High-end Standard 6 sealing unit Dispenser variably mountable Intuitive user guidance via colored touch panel Electromechanically driven aluminum rollers ensure an optimal product transport Continuously adjustable conveyor speed from 0.2to 1.0m/s Bundle positioning via increments by metrical input of the strapping positions Open design without protective coverings - CE marking inclusive conformity declaration Infeed side guidance Extremely low energy consumption

Request for a quote

MOSCA GMBH

Germany

•Corrosion-resistant ultrasonic sealing system with electronic self-calibration •High-end Standard 6 sealing unit •Wear-free DC drives with integrated electronics •Stepless turnable control panel for many-sided operation •Adjustable strap tension via control panel •Switching from maximum to material-friendly Ecospeed in the control •Quick strap coil change •Automatic strap threading system •Strap end detection with ejection of remaining strap •Automatic strap loop ejection •4 castors, 2 of them lockable (Ø 80 mm) •CE marking inclusive conformity declaration •Potential-free contacts to upstream and downstream machines •Continuously adjustable conveyorspeed from 0-1 m/s •Parameter control panel for setting strapping parameters •Selector switch for pass, single, double or multiple strapping •Machine completely corrosion-resistant (main use of V4A stainless steel) •IP 56 protection class design •Sensitive components (e.g. motors) are equipped with additional covers

Request for a quote

MOSCA GMBH

Germany

• SoniXs Utrasonic sealing unit in standard-6 version • Easy accessibility and tool-free dismantling of strap path components • Stepless turnable operation panel (0° - 180°) for many-sided operation • Adjustable strap tension via potentiometer • Programmable strap tension value • Strap coil changeable from the front and the side • Automatic strap coil change and threading system • Strap end detection with ejection of remaining strap • Automatic strap loop ejection • Extremely low energy consumption • Stand-by mode • 4 castors, 2 of them lockable • CE marking inclusive conformity declaration • Soft strapping selectable for sensitive packages • Easy operation over digital display in the control panel • Potential-free contacts to upstream and downstream machines • Continuously adjustable conveyor speed from 0.1 to 1.0 m/s • Parameter control panel for setting strapping parameters • Selector switch for single, double or multiple strapping

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MOSCA GMBH

Germany

• Top-mounted SoniXs ultrasonic sealing unit • Up to four strap lances for palletized products • Strap guide distance of 440, 625 and 810 mm • 1 or 2 sealing units laterally movable • Siemens PLC control system • Operation via Siemens 9” touch panel • Can be integrated into any production line • Potential-free contacts to upstream and downstream machines • Strapping with medium compression [up to 30,000 N – version KC_] • Strapping with high compression [up to 50,000 N – version KP_] Different Models: [K_R] Basic Model \ Driven roller conveyor [K_K]-Version \ Driven roller conveyor with lift turncross [K_Z]-Version \ Driven roller conveyor with centering device [K_A]-Version \ Driven roller conveyor with lift turncross and centering device [K_T]-Version \ Driven roller conveyor with turntable [K_S]-Version \ Driven roller conveyor with turntable, laterally moveable

Request for a quote

MOSCA GMBH

Germany

• SoniXs Ultrasonic sealing unit in standard-6 version • 4 swivel castors, 2 of them are lockable • Strap end detection with ejection of remaining strap • Easy accessibility and tool-free dismantling of strap path components • Easy operation over digital display in the control panel • CE marking inclusive conformity declaration • Extremely low energy consumption [MC] • Flexible foot pedal for manual strap release • Tool-free dismantling of the table plate [TRC] • Potential-free contacts to upstream and downstream machines • Selector switch for single, double or multiple strapping • Infinitely adjustable conveyor speed from 0.1 to 1.0 m/s • Optimization of the strapping processes by machine adaptation to defined package dimensions • Electromechanically driven aluminium rollers ensure an optimal product transport • Tool-free dismantling of roller system • Pneumatic hold-down device with manual prepositioning • Bundle positioning via time

Request for a quote

MOSCA GMBH

Germany

• SoniXs Utrasonic sealing unit in standard-6 version • Can be integrated into most production lines • Easy accessibility and tool-free dismantling of strap path components • Dispenser variably mountable • Hinged table top made of stainless steel • Adjustable strap tension via control panel • Easy operation via digital display in the control panel • Manual strapping release via pushbutton in the control panel • Stepless turnable control panel (0° – 180°) for many-sided operation • 4 castors (all lockable) • Extremely low energy consumption • CE marking inclusive conformity declaration

Request for a quote

MOSCA GMBH

Germany

KKOV 315, Basic Model Laterally friction-weld sealing Height moveable, horizontal arch Sealing unit, moveable laterally to the package PLC control Operation via 7" touch panel 10 freely configurable programs with up to 10 strapping positions Can be integrated into most production lines Potential-free contacts to upstream and downstream machines KOB 315, Special Version Like basic model KOV 315; additionally equipped with 2-side aligning device KOH 315, Special Version Like basic model KOV 315; additionally equipped with 4-side aligning device Options: SoniXs Ultrasonic sealing system Vertical edge protection applicator Three-part signal light including low strap indication Air conditioning equipment Strap sealing unit BSG 4 Data interface KSR-2 DC sealing unit HL sealing unit with floating head Design with operator button in addition to touch panel Structural colour according to RAL-scale

Request for a quote

MOSCA GMBH

Germany

• SoniXs Ultrasonic sealing unit • Strap dispenser • Potential-free contacts to upstream and downstream machines • Complete electric control for automatic and semiautomatic operation in the operator panel • Siemens PLC control with operator button Options: • Three-part signal light including low strap detection • HL sealing unit with floating head (up to 5,000 N strap tension) • Cable marking • Chassis with flanged rollers • Chassis for conveying height > 800 mm • Manual scantling device (80 x 80 – 100 x 100 mm)

Request for a quote

MOSCA GMBH

Germany

• SoniXs Ultrasonic sealing unit in standard-6 version • Potential-free contacts to upstream and downstream machines • High sealing tension due to a minimum distance from package to sealing unit • Programmable control with panel inclusive manual control with functional sequence of strapping control • Adjustable strap tension via touch panel • Low-wear, controlled strap path system • Stroke of strap guide frame via belt drive • Strap end detection with ejection of remaining strap • Wear-free DC drive, brushless motor technology • 10 freely configurable programs with up to 10 strapping positions

Request for a quote

MOSCA GMBH

Germany

— Ultrasonic sealing system with electronic self-calibration — Can be integrated into most production lines — Flap frame with magnetic locking — High-end Standard 6 sealing unit — Easy accessibility and tool-free disassembly of strap path components — Dispenser variably mountable — Hinged table top made of stainless steel — Adjustable strap tension via control panel — Easy operation via digital display in the control panel — Manual strapping release via pushbutton in the control panel — Stepless turnable control panel (0°-180°) for many-sided operation — 4 castors — Extremely low energy consumption — Frame size gradation in 200 mm steps — Structural coating RAL 5010, gentian blue

Request for a quote

MOSCA GMBH

Germany

• Dispenser variably mountable • 4 castors – Ø 125 mm (all lockable) • Parameter control panel for setting strapping parameters • Corrosion-resistant SoniXs Ultrasonic sealing unit in standard-6 version • Easy accessibility and tool-free dismantling of strap path components • Stepless turnable control panel (0 – 180°) for many- sided operation • Adjustable strap tension via control panel • Quick strap coil change • Strap end detection with ejection of remaining strap • Machine completely corrosion-resistant (main use of V4A stainless steel) • IP 56 protection class design • Sensitive components (e. g. motors) are equipped with additional covers • CE marking inclusive conformity declaration • Extremely low energy consumption

Request for a quote

MOSCA GMBH

Germany

Modular construction High-end Standard 6 sealing unit Narrow sealing unit with ultrasonic sealing system Pneumatic hold-down device Pneumatic side pusher with opposite buffer plate Signal exchange via 16-pin contact Easy accessibility and tool-free disassembly of strap path components Low-wear DC drives with integrated electronics Stepless turnable operation panel (ECOB) for many-sided operation Adjustable strap tension via operation panel Programmable strap tension value Switching from maximum to material-friendly Eco-speed in the control Cycle counter integrated in the control Quick strap coil change Strap coil changeable from the front and the side Automatic strap threading system Strap end detection with ejection of remaining strap Automatic strap loop ejection Extremely low energy consumption Stand-by mode 4 castors, 2 of them lockable CE marking inclusive conformity declaration Structural painture in RAL 5010, gentian blue

Request for a quote

MOSCA GMBH

Germany

• Heat-weld sealing unit in standard-3 version • Wear-free DC drive, brushless motor technology • Strap end detection with ejection of remaining strap • Easy strap coil change and threading system • Soft strapping selectable for sensitive packages • Low-wear, controlled strap path system • Adjustable strap tension via potentiometer • Energy-saving drives • Electronic control • Hinged front table top • Sturdy foot pedal for cycle start • 4 castors of which 2 are lockable • Table top length 600 mm or alternatively 700 mm or 800 mm • CE marking inclusive conformity declaration

Request for a quote

MOSCA GMBH

Germany

• SoniXs Utrasonic narrow sealing unit in standard-7 version • B&R PLC control • Easy strap coil change and threading system • Strap end detection with ejection of remaining strap • Energy-saving drives • Adjustable strap tension via webHMI • Low-wear, controlled strap path system • 4 castors, 2 of them are lockable • Quick strap coil change • Flexible dispenser alignment • 3 definable recipes for quick adjustment of parameters during product change • CE marking inclusive conformity declaration

Request for a quote

MOSCA GMBH

Germany

• Inline strapping parallel to flute • SoniXs Ultrasonic needle sealing unit • Automated setup system resets to the dimensions of the first bundle of the new size [Teach-In] • 6-sided electromechanical package alignment • Potential-free contacts to upstream and downstream machines • Siemens PLC control with touch panel • Stand-by-mode reduces wear and energy consumption • Lateral automatic adjustment device • Automatic machine adaptation to package dimensions via adjustable recipes [500] • Sealing unit removing device

Request for a quoteResults for

Packaging and packing - Import exportNumber of results

76 ProductsCompany type