- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- modular structures

Results for

Modular structures - Import export

ZOLLER & FRÖHLICH GMBH

Germany

With the software Z+F SynCaT®, Zoller+Fröhlich creates a connection between the Z+F PROFILER® 9012 and external positioning and navigation systems. SynCaT stands for synchronization, calibration and transformation - also representing the main tasks of the software. Z+F SynCat® includes all the features below: Calibration: Processing of calibration parameters due to different system integrations (translation, rotation offsets between the coordinate systems of the navigation-unit (trajectory) and the Z+F PROFILER® 9012 laser scanner) Synchronization: Synchronize Z+F PROFILER® 9012 laser scanner data with trajectory data and generate 3D point cloud files Transformation: Transform 3D point cloud data to different local coordinate systems and apply different local/global height correction models (geoid correction files) Correction: Individual offset estimation referring to predefined ground control points (GCP’s) Z+F SynCaT® is a modular structured mobile mapping software.

Request for a quote

JACOB GMBH

Germany

Whenever pre-assembled cables need to be led into a housing, the cable entry system KADL is the perfect solution. KADL is installed with one click - easy and timesaving. The modular structure allows a step-by-step installation of 3 to 25 cables. With 16 different grommets a wide clamping range from 3 to 32,5 mm can be covered. - For applications where you need to insert and seal pre-assembled cables with connectors into housings - Tool-free entry and connecting technology for machines and equipment - Temperature range -30 °C to +100 °C - Protection grade IP65 - UL 514B - 12 different frame combinations with 16 sizes of grommets (accessory) - Click-in assembly at wall thickness from 1,5 - 2,0mm - For walls with thickness larger 2,0 mm the KADL can be fixed with standard screws

Request for a quote

BETONBAU GMBH UND CO. KG

Germany

The stable structure of Betonbau modular units enables factory equipping with plant and equipment. Factory installation is particularly economical, considerably reducing your co-ordination outlay for many minor tasks on the construction site. On-site commissioning time is considerably reduced as a result. The spectrum in this respect ranges from the basic 230V/400V installation for lighting, heating and socket circuits to the integration of emergency lighting and explosion protection. We can supply a standardised sub-distribution system with the delivery if requested, meaning you simply have to connect everything on site. Cable trays, electrical heating equipment, ventilators, air conditioning systems and sanitary equipment can be fitted in the manufacturer's facilities if required. Experienced engineers and master craftsmen plan and monitor the production and, together with our installation technicians, ensure that quality and safety standards are reliably realised.

Request for a quote

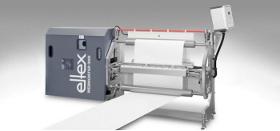

ELTEX-ELEKTROSTATIK-GMBH

Germany

In the past, Eltex Remoistening systems have guaranteed high quality printed products mainly on fastrunning and wide machines. The WEBMOISTER 3000 ensures high-quality products in all heatset web offset machines. Using a new nozzle concept, both lighter and heavier grammages can be remoistened at all web speeds with ultimate precision and homogeneity. The new pneumatic atomizing nozzles are capable of applying smallest water quantities without developing waste water. The modular structure of the nozzle bar allows the WEBMOISTER 3000 to remoisten paper webs in widths of as much as 3 meters. In heatset web offset printing, paper loses moisture during drying. The WEBMOISTER 3000 remoistening system increases the water content in the paper after drying, returning to the level required and thus guarantees high quality in all heatset web offset products.

Request for a quote

DAMBACH LAGERSYSTEME GMBH & CO KG

Germany

The MULTIFLEX from DAMBACH sets new standards for throughput, flexibility and efficiency. It comprises three perfectly coordinated modules with seamless interfaces: the proven COMPACT SHUTTLE, the high-performance vertical conveyor LIFT and the newly developed CARRIER. In analogy to the small-part-shuttle technology, the MULTIFLEX enables multi-deep storage and highly dynamic commissioning of various types of pallets. In addition, the compact design of the DAMBACH-shuttles and vertical conveyors ensure a very high storage density. With this modular structure, the MULTIFLEX is flexibly adaptable to different challenges. The fields of application for this pallet-shuttle-system are as variable as its three configurations. It is suitable, for instance for cold storage, buffer storage, dispatch warehouses, sequence storage, commissioning warehouses or supply warehouses – But also for compact warehouses with low throughput.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OPTIMA NONWOVENS GMBH

Germany

For packaging panty liners or sanitary napkins (regular or ultra thin), either flat or folded and wrapped, high performance and a huge variety of packages are in demand. Adapted to these requirements, only the best machinery offers maximum flexibility and ideal product protection. Fully automated machinery by the OPTIMA ON3/OS2 bag packer and packaging machine delivers the optimum process quality to deliver lowest cost per pack to our customers. Modular machine structure Multiple product rows possible Quick and easy change-over Premade polyethylene bags on wickets Tilting cassette

OPTIMA NONWOVENS GMBH

Germany

High packaging quality is always the crucial factor. The OPTIMA HS/OS3 bag packer and packaging provides the right packaging to best showcase logos and printing at the point of sales. The adjustable high compression further enhances quality and brings with it a number of advantages in logistics. Optima Nonwovens packaging machines are flexible: The machines can be adjusted quickly and easily for a large range of formats, format sets and modules. Fully automatic high-speed stacker for baby diapers Quick and easy change-over Quality gate Modular machine structure Designed for easy maintenance

OPTIMA NONWOVENS GMBH

Germany

Whether compressed large packages or sales packages with excellent visual and haptic quality, this segment is characterized by strongly varying requirements. Modular packaging machines such as the OPTIMA LS/OS8 can meet all these needs at the same time. Industry-leading outputs combined with very high machine reliability ensure productivity, while additional quality control functions for both, process and product, further sets these units apart from the competition. The OPTIMA OS8 bagger can be ideally combined with the OPTIMA LS stacker. Not only can an unrivalled range of formats be flexibly processed with this system; the integrated modules and additional (control) functions open up a new dimension of packaging process design. Modular machine structure Multiple product rows possible Stack turning possibility Quick and easy change-over Premade polyethylene bags on wickets

OPTIMA NONWOVENS GMBH

Germany

The OPTIMA OSR bag packer and packaging machine can handle tissue products of all types, supporting all required roll product formations of kitchen towels and bathroom tissue in one or multiple layers. Optima Nonwovens machines and modules are designed to meet your specific requirements. Bathroom tissue and kitchen towel rolls can be packed on Optima equipment in pre-made polyethylene bags. This is how Optima Nonwovens has maintained its status as a leader in the industry. Full servo technology Modular machine structure Taylor made solutions to match individual requirements Small foot print Quick and easy change-over Single and double layer packages possible Premade polyethylene bags on wickets Point of sale packages Carry-handle possible Perforation for easy bag opening possible

OPTIMA NONWOVENS GMBH

Germany

For packaging light incontinence products, high performance and a huge variety of packages are in demand. Adapted to these requirements, the OPTIMA HS/OSI bag packer and packaging machine offers maximum flexibility and ideal product protection. Stackers from Optima Nonwovens can synchronously accommodate the infeed of incontinence products from manufacturing machines. The products are counted by the stacker and arranged in pre-defined layouts. As the link to the packaging machine, the stacker quickly and gently supplies the products to the further packaging process. The OPTIMA OSI bagger delivers high outputs and can accommodate an extremely broad range of formats and larger packages. Modular machine structure Quick and easy change-over Multiple product rows possible Tilting cassette Premade polyethylene bags on wickets

RATEC GMBH

Germany

Visionary concepts come true with upcrete® modular moulds – even complex concrete structures can be produced with smooth surfaces on all sides. The room module mould with “flying” shrinking core was the fi rst room cell mould developed in Hockenheim and was used for a modular housing project for a Peruvian customer. This mould variant is based on the upcrete® technology, in which self-compacting concrete is pumped from below into a closed mould. This process allows the concrete to optimally distribute within the mould and yields smooth surfaces on all sides, as well as precise edges and recesses. Another advantage is that the structure can be produced in its fi nal installation position, which means that subsequent turning is no longer required.

Request for a quoteResults for

Modular structures - Import exportNumber of results

12 ProductsCompany type