- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- mobile lifting

Results for

Mobile lifting - Import export

SITEMA GMBH & CO KG

Germany

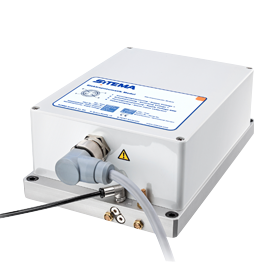

Mechanical Valve Actuator MVA Rod leaving clamping head Auto Bleeder Mechanical Safety Catcher KRM Electric Locking Unit KFE Special customer requirements Applications Overview Presses Machine Tools Automatization + Feeders Lifting Gear + Mobile Hydraulics Production Technology Special Machinery CAD Download Contact Electropneumatic module EPM The Electropneumatic Module EPM acts as interface between (electrical) power supply / control and a pneumatic SITEMA clamping head. All pneumatic SITEMA clamping heads with an operating pressure of up to 4 bar and an operating volume of up to 220 cm³ can be pneumatically controlled by the EPM. It is also possible to operate several clamping heads in parallel with one EPM. The EPM is controlled by a 24V supply and switching voltage. The outlet pressure which is required to open or keep open a pneumatic clamping head is controlled by a control signal. If the voltage fails or the input signal is switched off, the pressure is...

Request for a quote

SITEMA GMBH & CO KG

Germany

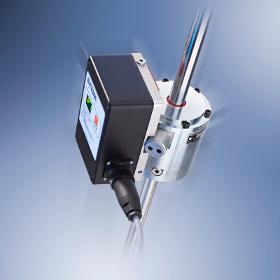

KFE Special customer requirements Applications Overview Presses Machine Tools Automatization + Feeders Lifting Gear + Mobile Hydraulics Production Technology Special Machinery CAD Download Contact Electric Locking Unit The electric Locking Unit KFE is used as a stepless locking device on round rods and holds axial forces in both load directions without axial play. It is used where hydraulic or pneumatic solutions are not possible. The holding force is created by the proven spring-operated clamping system as it is used in SITEMA’s hydraulically or pneumatically operated Locking Units. At a drop of the control voltage or in case of failure of the electric supply, the Locking Unit KFE clamps automatically. Therefore, it is also suitable for use in safety relevant applications. To operate the Locking Unit KFE, a supply voltage of 24 V and a control signal for the input command “clamp/release” are sufficient. The Locking Unit is self-monitoring and provides output signals...

Request for a quote

SITEMA GMBH & CO KG

Germany

KRM Electric Locking Unit KFE Special customer requirements Applications Overview Presses Machine Tools Automatization + Feeders Lifting Gear + Mobile Hydraulics Production Technology Special Machinery CAD Download Contact Mechanical Safety Catcher The Mechanical Safety Catcher KRM is operated purely mechanically and requires neither a hydraulic nor a pneumatic system for control. The clamping head is kept open mechanically and acts upon rupture of the suspension (rope, belt, chain, etc.). The energy of the falling mass is then used to generate the clamping force. In applications where lifted loads can be dangerous in case of rupture of the suspension device, Safety Catchers KRM are used to protect people and assure accident prevention. Safety Catchers KRM secure the load at any point of the stroke in a mechanically safe and absolutely reliable way. Due to the principle of self-reinforcing clamping, a very high level of safety is reached. Application example Packing...

Request for a quote

SITEMA GMBH & CO KG

Germany

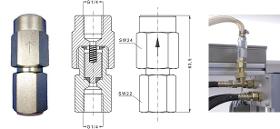

Mechanical Safety Catcher KRM Electric Locking Unit KFE Special customer requirements Applications Overview Presses Machine Tools Automatization + Feeders Lifting Gear + Mobile Hydraulics Production Technology Special Machinery CAD Download Contact Auto Bleeder The SITEMA Auto Bleeder has been specially designed for the use with a SITEMA clamping head. It makes sure that the hydraulic system is constantly bled. Air bubbles in the hydraulic fluid might combust spontaneously under certain conditions (so-called Diesel effect). As a consequence, seals and sealing surfaces can be damaged, causing leakages. Clamping heads are especially susceptible for this phenomenon, as they have only a very small hydraulic volume and are not flushed through at each activation. Air can therefore easily accumulate in the clamping head. This is the reason why the usual initial bleeding at commissioning is often not enough, especially when the line leading to the clamping head points upwards...

Request for a quote

SITEMA GMBH & CO KG

Germany

Rod leaving clamping head Auto Bleeder Mechanical Safety Catcher KRM Electric Locking Unit KFE Special customer requirements Applications Overview Presses Machine Tools Automatization + Feeders Lifting Gear + Mobile Hydraulics Production Technology Special Machinery CAD Download Contact Mechanical Valve Actuator MVA Secure the rupture of a chain with the full comfort of a pneumatic SITEMA clamping head When a load has to be secured against rupture of a suspension device (e.g. a chain), many customers use our Mechanical Safety Catcher KRM. This unit has the advantage to hold the load immediately upon rupture of the suspension device. Additional sensors to detect rupture of a chain are not necessary. On the other hand, it is not possible to activate the KRM in a user-defined position without rupture of the suspension device, e.g. for maintenance purposes. Here, the Mechanical Valve Actuator MVA comes to your rescue. It is simply put between the suspension device and the...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

YSTRAL GMBH MASCHINENBAU + PROCESSTECHNIK

Germany

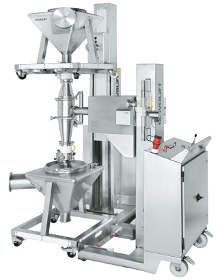

Flexibility in chemical, food, cosmetic and pharmaceutical production. With only one machine, different products and product quantities can be produced with the most suitable tool. The tool shaft can be easily disconnected from the drive, e.g. for cleaning, while continuing to work with a second shaft. The tool shaft has a shaft bearing separate to the motor, which is driven via a plug connection. The possibility of adding a mobile lifting stand offers additional flexibility. Batch sizes from 5 to 1,000 l are covered by the X50, X100 and X200 series. The X100/X50 adapter enables an X100 to be used to produce batches ranging from 5 to 1,000 l. By simply exchanging the shafts, it is possible to conduct jet mixing, mixing dispersion, dispersion, powder aspiration and wetting. Maximum flexibility creates investment security - short set-up times and easy handling.

Request for a quote

HAACON HEBETECHNIK GMBH

Germany

Specialised lifting systems for mobile devices Depending on the application of the supports, the following technical parameters can be achieved: Container carrying capacity from 2.5 t to 20 t, Lifting heights from 500 mm to 1,750 mm (Optional maximum: 2,000 mm), Attachment to ISO corners and Position Control. Innovative inclinometer-based position control is a special characteristic of our lifting systems and allows lifting and lowering action parallel to the ground during loading operations in uneven terrain, automatic initial inclination registration, inclination offset to zero degrees, control precision: +/- 0.2 degrees, safety shutdown when the inclination exceeds 3.5 degrees (or more, if required). Individual support control unit available as optional attachment.

Request for a quote

HAACON HEBETECHNIK GMBH

Germany

Specialised lifting systems for mobile devices Depending on the application of the supports, the following technical parameters can be achieved: Container carrying capacity from 2.5 t to 20 t, Lifting heights from 500 mm to 1,750 mm (Optional maximum: 2,000 mm), Attachment to ISO corners and Position Control. Innovative inclinometer-based position control is a special characteristic of our lifting systems and allows lifting and lowering action parallel to the ground during loading operations in uneven terrain, automatic initial inclination registration, inclination offset to zero degrees, control precision: +/- 0.2 degrees, safety shutdown when the inclination exceeds 3.5 degrees (or more, if required). Individual support control unit available as optional attachment.

Request for a quote

HAACON HEBETECHNIK GMBH

Germany

Specialised lifting systems for mobile devices Depending on the application of the supports, the following technical parameters can be achieved: Container carrying capacity from 2.5 t to 20 t, Lifting heights from 500 mm to 1,750 mm (Optional maximum: 2,000 mm), Attachment to ISO corners and Position Control. Innovative inclinometer-based position control is a special characteristic of our lifting systems and allows lifting and lowering action parallel to the ground during loading operations in uneven terrain, automatic initial inclination registration, inclination offset to zero degrees, control precision: +/- 0.2 degrees, safety shutdown when the inclination exceeds 3.5 degrees (or more, if required). Individual support control unit available as optional attachment.

Request for a quote

SERVOLIFT GMBH

Germany

The broad applications spectrum of SERVOLIFT milling and sieving equipment leads to flexible and user-friendly solutions in combination with handling systems. The areas of application stretch from controlled sieving in order to remove contamination from raw materials to fractionation, calibration to deagglomeration. Sieve mills, vibration sieve machines or inline sieve equipment in combination with mobile or stationary lifting systems provide a flexible, compact and easy-to-clean system. Size as needed Technical description Stainless steel or cGMP/FDA compliant designs Use as sieve mills (cone mills), hammer mills, oscillating sieve mills Various throughput depending upon the product and particle size Lifting height can be customized Broad control designs, from simple microcontrollers with digital displays to PLC controls Explosion-protected designs in adherence to Atex Zone 1/21 and 2/22.

Request for a quote

SERVOLIFT GMBH

Germany

These types of machines are used for a variety of applications when combined with process machines. The use of cone mills, hammer mills, vibration sieves, sifters, mobile for various areas or stationary. The broad applications spectrum of these devices can be seen in weighing for raw materials preparation or granulation for calibration, to name two examples. The take-up system is designed and adapted depending upon the process machines and the specified runs. Take-up of various additional devices Technical description cGMP-compliant design Mobile or stationary or combinable for high flexibility Adapted take-up system, depending upon the process machines Variable, adjustable lifting function - for mobile units with telescoping designs for low drive-through heights Function extensions through the integration of tilting and pivoting functions Various containment designs, such as low-dust connections up to high-containment solutions Extensive control designs, depending upon...

Request for a quoteResults for

Mobile lifting - Import exportNumber of results

12 ProductsCompany type