- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- wood milling machines

Results for

Wood milling machines - Import export

EUGEN LÄGLER GMBH

Germany

The first floor sanding machine developed by Eugen Lägler! Due to its ease of operation and maintenance, it has proven its value in the rental business, especially in the centrifugal sanding drum version. The ELF - which is constantly being improved in detail - can be acquired with either a conventional sanding drum or the modern LÄGLER® centrifugal sanding technology. The drum sanding machine convinces with its high performance and simple application. The integrated bracket facilitates the transport of the machine. Applications with the ELF: The ELF is the reliable drum sanding machine for working on small as well as on large areas. It is mainly used for sanding wooden floors. Nevertheless, it can also be used in conjunction with the IGEL milling drum for milling works, such as removing multiple layers of finish from planks. The version with centrifugal drum is very user-friendly. This makes the ELF also the ideal wooden floor sanding machine for the rental business.

Request for a quote

EUGEN LÄGLER GMBH

Germany

Worldwide: known, used and admired across the globe! The HUMMEL® is powerful, efficient and reliable. With its optimal dust extraction you are able to work almost dust free. The sophisticated and durable technology for perfect sanding along with its enormous performance quality make the HUMMEL® the undisputed number one machine for sanding wooden floors. It has been convincing craftsmen all over the world for over half a century. It is simultaneously powerful and easy to operate and maintain. Both changing the sanding belt and dismantling the machine are extremely simple. The HUMMEL® can be ordered with or without the powerful LED work light. Applications with the HUMMEL®: The HUMMEL® belt sander is mainly used for sanding wooden floors. It enables precise and economical sanding of both small and large surfaces.

Request for a quote

SIKO GMBH

Germany

Version with two counters (4 or 5 decades) and fine reading. Predestined for use with wood milling machines. Hollow shaft, max. Ø 30 mm. Display can be designed for “mm” or “inch”.

Request for a quote

SIKO GMBH

Germany

Profile DA10R/1: Version with two counters (4 or 5 decades) and fine reading Predestined for use with wood milling machines Hollow shaft, max. Ø 35 mm Display can be designed for “mm” or “inch”

Request for a quote

GEBR. HELLER MASCHINENFABRIK GMBH

Germany

The 5-axis machining centres from the HF series are optimally equipped to meet the exacting requirements of modern production processes. Enabling 5-sided and simultaneous 5-axis machining, they allow you to handle many different tasks on a single machine. Highly productive and flexible, with easy operation and maintenance, available with pallet changer or table loading. The second generation of the HF series provides numerous optimisations, including new spindle units with increased performance and the advantages of the HELLER zero-spindle system for minimised life cycle costs. Moreover, the option of a second drive in the Z-axis allows for even more universal application, including single-part production. In combination with the proven HELLER DNA of productivity, precision and reliability, they guarantee you increased performance, precision and flexibility for the production of your workpieces.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

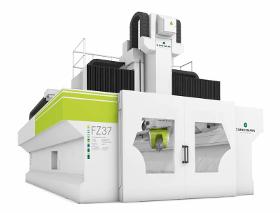

F. ZIMMERMANN GMBH

Germany

The portal milling machine FZ40 compact is designed for the machining of hard materials as well as aluminum. The inherently rigid machine structure allows for simultaneous 5-axis high speed machining. This compact machine, with its solid cast base does not require a foundation. The machine table is integrated into the cast baseplate, which allows up to 16 metric tons of table load. Eight mounting elements of the FZ40 compact reduce vibration – the basic requirement for high accuracy and optimum surface quality. The sidewalls are filled with a special dampening concrete mix to further enhance performance. The machine has a fully enclosed working space with a fixed machine table. The structural sound overhead gantry with a reinforced Z-ram make up the moving masses. By adding our new dynamic milling head VH60, Zimmermann has created a powerful performer. The combination of high strength and rigidity, constant moving masses and dynamic drives, will meet the industries high demands.

Request for a quote

F. ZIMMERMANN GMBH

Germany

With the FZ100 Portal Milling Machine Zimmermann has managed to achieve 6-axis machining using the patented in-house developed M3ABC 3-axis Milling Head. This concept sets new standards in the volume machining of aluminium, composite and model making materials as well as in the High Speed Cutting of steel and cast iron, where conventional 2-axis fork heads with A- and C-axis have long reached their limits in the 5-axis simultaneous machining. Advantages: - Machining four times faster is possible - Perfect quality thanks to the six axes - Highest accuracy possible

Request for a quote

F. ZIMMERMANN GMBH

Germany

The 5-axis portal milling machine FZ 25 is a universal solution for the machining of highly complex and at the same time voluminous components. Model materials as well as composites through to light alloys can all be machined with this HSC gantry machine. This machine range fulfils the specific requirements of many sectors: - In the automobile design where large models need to be produced (e. g. cars on a scale of 1:1). - In pattern and tool making, especially in connection with very large workpieces with deep contours need to be machined (e. g. large rotation-symmetric moulds such as tanks and pools, etc.). - In the boatbuilding and shipbuilding industries, where huge work areas are required in all three axes, since the components are often elongated in shape. - In the aircraft industry, e. g. for milling panels, other large parts and components with extreme contours. In the wind energy industry with its long thin blades and bulbous hubs.

Request for a quote

F. ZIMMERMANN GMBH

Germany

Universal metal cutting machine. Designed for highly dynamic machining of different materials. High-speed machining ensures efficient milling results. Advantages: - outstanding price-performance ratio - very broad application spectrum - high-quality universal head for simultaneous machining

Request for a quoteResults for

Wood milling machines - Import exportNumber of results

10 ProductsCompany type