- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- welding solutions

Results for

Welding solutions - Import export

BRUGGER GMBH MAGNETSYSTEME

Germany

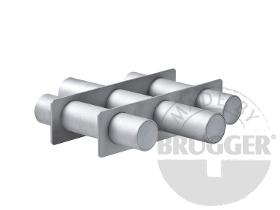

The above mentioned filter bars are our standard designs. Here the end pieces are not sealed tight and therefore only suitable for dry applications. Not available ex stock, manufactured on demand Alternative to the standard we also offer individual solutions: » Seal-welded model for use in liquids (e.g. water, coolant) » High-quality stainless steel enclosure for use in food production » Increasing the max. operating temperature up to 350 °C » Manufacture of individual, not standardised sizes

Request for a quote

BRUGGER GMBH MAGNETSYSTEME

Germany

The above mentioned filter bars are our standard designs. Here the end pieces are not sealed tight and therefore only suitable for dry applications. Not available ex stock, manufactured on demand Alternative to the standard we also offer individual solutions: » Seal-welded model for use in liquids (e.g. water, coolant) » High-quality stainless steel enclosure for use in food production » Increasing the max. operating temperature up to 350 °C » Manufacture of individual, not standardised sizes

Request for a quote

BRUGGER GMBH MAGNETSYSTEME

Germany

The above mentioned filter bars are our standard designs. Here the end pieces are not sealed tight and therefore only suitable for dry applications. Not available ex stock, manufactured on demand Alternative to the standard we also offer individual solutions: » Seal-welded model for use in liquids (e.g. water, coolant) » Other fastening options (e.g. external, internal threads and threads measured in inches) » High-quality stainless steel enclosure for use in food production » Increasing the max. operating temperature up to 350 °C » Manufacture of individual, not standardised lengths up to 2000 mm

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

LIPP® Tank Refurbishing Quantities change and existing tanks become too small – these are also problems that frequently arise. In such cases, the mobile machine technology from Lipp using the LIPP® DoubleSeam System or the LIPP® welding technique offers a solution that is as simple as it is costeffective, while being extraordinarily stable. Tanks can be installed on site in any size required and can be placed in an existing steel or reinforced concrete basin using a mobile crane. The existing tank volume is utilised, eliminating the need for expensive demolition work. There is also a range of materials to choose from for the tank itself so that it can be optimally matched to the intended application. VERINOX®, the combination material developed by LIPP® consisting of galvanised steel (for the outside of steel containers) and stainless steel (for the inside of containers), is characterised in particular by the excellent costbenefit ratio that it offers.

Request for a quote

BRUGGER GMBH MAGNETSYSTEME

Germany

The above mentioned filter bars are our standard designs. Here the end pieces are not sealed tight and therefore only suitable for dry applications. Not available ex stock, manufactured on demand Alternative to the standard we also offer individual solutions: » Seal-welded model for use in liquids (e.g. water, coolant) » High-quality stainless steel enclosure for use in food production » Increasing the max. operating temperature up to 350 °C » Manufacture of individual, not standardised sizes

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

SYSTEM FOR THE COST EFFECTIVE REFURBISHING OR VOLUME EXPANSION OF CONTAINERS OR TANKS Changing conditions, material wear, a change to the filling medium – these are just a few of the factors that lead to the replacement of containers used in industry or at municipal sewage treatment plants. Quantities change and existing containers become too small – these are also problems that frequently arise. In such cases, the mobile machine technology from Lipp using the LIPP Double Seam System or the LIPP welding technique offers a solution that is as simple as it is cost effective, while being extraordinarily stable. Containers can be installed on site in any size required and can be placed in an existing steel or reinforced concrete basin using a mobile crane. The existing container volume is utilised, eliminating the need for expensive demolition work. Utilisation of the existing container volume High stability, leak tightness and safety Continuous adaptation to existing container

Request for a quote

WEBER ULTRASONICS AG

Germany

For agile welding tasks in close quarters, small lots or prototyping, the HSM Hand Welding Module is the perfect solution. This ergonomically shaped tool is splash-proof and convinces with durability. The HSM is always configured to your specific needs and comes with a Sonotrode tailored to your task.

Request for a quote

BRUGGER GMBH MAGNETSYSTEME

Germany

The above mentioned filter bars are our standard designs. Here the end pieces are not sealed tight and therefore only suitable for dry applications. Not available ex stock, manufactured on demand. Alternative to the standard we also offer individual solutions: » Seal-welded model for use in liquids (e.g. water, coolant) » Other fastening options (e.g. external, internal threads and threads measured in inches) » High-quality stainless steel enclosure for use in food production » Increasing the max. operating temperature up to 350 °C » Manufacture of individual, not standardised lengths up to 2000 mm

Request for a quote

BRUGGER GMBH MAGNETSYSTEME

Germany

The above mentioned filter bars are our standard designs. Here the end pieces are not sealed tight and therefore only suitable for dry applications. Not available ex stock, manufactured on demand. Alternative to the standard we also offer individual solutions: » Seal-welded model for use in liquids (e.g. water, coolant) » High-quality stainless steel enclosure for use in food production » Increasing the max. operating temperature up to 350 °C » Manufacture of individual, not standardised sizes

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

In order to make use of the many benefits of ultrasonic welding, Herrmann Ultraschall realizes special solutions for many other packaging variants. Thanks to long-term experience in terms of key functions, such as guiding, movement travel, drive, and force build-up, it is possible to implement customer requirements, such as cycle time, and space specifications in a targeted and efficient way.

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

This precisely guided system safely and quickly seals through product residues in the seal area. Narrow seals and reduced head space above the product contents save packaging materials. Operational costs are significantly reduced while the quality of products is ensured. Elements, such as film pusher units, temperature adjustment of weld tools, and special solutions for machines with lateral fold-open equipment, are optionally available.

Request for a quoteResults for

Welding solutions - Import exportNumber of results

12 ProductsCompany type

Category