- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- vision systems

Results for

Vision systems - Import export

PAUL LEIBINGER GMBH & CO. KG

Germany

LEIBINGER is offering its customers a straightforward and cost-effective option for quickly and reliably checking the product marking applied by a LEIBINGER inkjet printer in the form of its V-check vision system. V-check does this by automatically comparing printed data such as letters, digits, logos or images against a reference sample, guaranteeing high production reliability.

Request for a quote

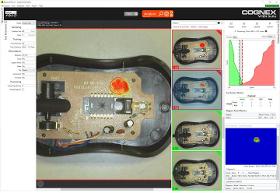

COGNEX CORPORATION

Germany

The In-Sight 5705 series offers high performance with high resolution making it the fastest 5MP self contained vision system in the world, supporting Gigabit Ethernet and the new blazing fast PatMax® Redline™ tool. The In-Sight 5705C offers color image filtering in addition to grayscale filtering and allows you to train multiple color models using the color library to identify which color the target part is. All models are equipped with a full library of proven Cognex vision tools. With the In-Sight EasyBuilder® configuration software, even the most powerful vision tools are accessible to users with little vision experience. For experienced users and complex applications, In-Sight 5705 includes scripting functionality as well as TestRun system validation and Cognex Connect suite of communications protocols.

Request for a quote

COGNEX CORPORATION

Germany

The In-Sight 5705 series offers high performance with high resolution making it the fastest 5MP self contained vision system in the world, supporting Gigabit Ethernet and the new blazing fast PatMax® Redline™ tool. All models are equipped with a full library of proven Cognex vision tools. With the In-Sight EasyBuilder® configuration software, even the most powerful vision tools are accessible to users with little vision experience. For experienced users and complex applications, In-Sight 5705 includes scripting functionality as well as TestRun system validation and Cognex Connect suite of communications protocols.

Request for a quote

COGNEX CORPORATION

Germany

In-Sight 8000 compresses an entire self-contained vision system in an amazingly small form factor. These vision systems are ideal for integrating into tight spaces on robots and hard-to-reach machinery anywhere on the production line. Every In-Sight 8000 vision system model delivers best-in-class performance. Most models are equipped with a full library of proven Cognex vision tools, including Pattern Matching, Filtering, Color tools, Inspect Defects and ID (1D/2D, OCR). In-Sight Explorer combines the guided step by step setup of EasyBuilder with the additional power and flexibility of the spreadsheet for greater control and customizing of application data. Also included is the new scripting function to simplify data-intensive tasks or complex final result logic. TestRun system validation, Cognex Connect suite of communications protocols and the Cognex Explorer control center gives you the tools you need to keep your line operating on schedule and at full throughput.

Request for a quote

COGNEX CORPORATION

Germany

The In-Sight 7900 series is a full-featured, high-resolution and flexible vision system that performs fast, accurate inspections of a wide range of parts across all industries. With a wide selection of field-changeable and user-configurable lighting and optics (Flexible Image Technology™ FIT™) the modular design is highly field-customizable to your application requirements. The In-Sight 7000 vision system is thoughtfully engineered with the full suite of powerful Cognex vision algorithms and convenient features to help you solve your applications easily and reliably, including a highly visible pass/fail LED indicator light ring around the camera body, an SD-card slot and an IP67-rated housing.

Request for a quote

COGNEX CORPORATION

Germany

In-Sight 8000 compresses an entire self-contained vision system in an amazingly small form factor. These vision systems are ideal for integrating into tight spaces on robots and hard-to-reach machinery anywhere on the production line. Every In-Sight 8000 vision system model delivers best-in-class performance. Most models are equipped with a full library of proven Cognex vision tools, including Pattern Matching, Filtering, Color tools, Inspect Defects and ID (1D/2D, OCR). In-Sight Explorer combines the guided step by step setup of EasyBuilder with the additional power and flexibility of the spreadsheet for greater control and customizing of application data. Also included is the new scripting function to simplify data-intensive tasks or complex final result logic. TestRun system validation, Cognex Connect suite of communications protocols and the Cognex Explorer control center gives you the tools you need to keep your line operating on schedule and at full throughput.

Request for a quote

COGNEX CORPORATION

Germany

The In-Sight 7800 series is a full-featured, powerful vision system that performs fast, accurate inspections of a wide range of parts across all industries. With a wide selection of field-changeable and user-configurable lighting and optics (Flexible Image Technology™ FIT™) the modular design is highly field-customizable to your application requirements. The In-Sight 7000 vision system is thoughtfully engineered with the full suite of powerful Cognex vision algorithms and convenient features to help you solve your applications easily and reliably, including a highly visible pass/fail LED indicator light ring around the camera body, an SD-card slot and an IP67-rated housing.

Request for a quote

BIZERBA SE & CO. KG

Germany

Efficient control of packaging and label content in labeling lines The Bizerba LabelSecure vision inspection system automatically checks label position and texts. Bizerba LabelSecure can be integrated in conveyor lines with dynamic checkweighers. Thereby offering a high level of flexibility and adaptability to existing systems. Used with an inline dynamic checkweigher the system will add another level of protection on your production line. Consider the Dynamic checkweigher CWEmaxx. The system will checkweigh and reject any over filled and under filled packages. In addition, the vision inspection system performance is impressive, automatic control of label position, texts and film colour. Any packages that do not conform to the programmed or set criteria will be rejected. Also, package sizes and bar codes are verifiable. All packages that fall outside of the date range set up in the Vision Inspection System will be rejected, Ensuring out of date or short sell by dated products...

Request for a quote

BIZERBA SE & CO. KG

Germany

Complete optical packaging inspection Vision inspection system SealSecure checks the seal and seams on the package, labels and information on the top and bottom or the sides of the products. The stand-alone vision inspection device detects non-conforming packages prior to packaging and rejects them, if there are product, package discrepancies or deviations. The staff are then immediately warned visually and audibly in order to be able to intervene and rectify the problem. Vision inspection system SealSecure prevents extensive and costly rework, eliminating claims and product recalls due to non-conforming packages. In addition, the Vision inspection system SealSecure ensures that only flawless products reach the market or end user. In addition, all the product images are saved in the production system and the relevant production reports are generated, the vision inspection system contributes to complete traceability of the production line. The Vision inspection system SealSecure...

Request for a quote

BIZERBA SE & CO. KG

Germany

Checkweighing for dry areas and non-food applications Bizerba CWDmaxx series checkweighers are designed as entry-level checkweighing models for up to 250 weighings per minute. With an IP54 protection level the CWDmaxx is the first choice for all applications not requiring wet cleaning. It is built with a modular construction allowing for configurations of up to 5 belt modules to be made on one checkweigher, tailored to the specific application or areas that it is sited. Additionally the checkweighing systems are extremely flexible. Due to the modular design all the Bizerba checkweighing systems can easily be integrated with existing inspection systems to include x-ray food, food metal detectors and vision inspection systems. You may also be looking for weigh price labelling systems. Our GLM-Ievo range can boast a labelling speed of up to 170 packages per minute. The dynamic checkweighing system CWDmaxx is ideal for non food, we have an entire range of inspection systems for all...

Request for a quote

BIZERBA SE & CO. KG

Germany

Standard Dynamic Checkweigher for quality assurance at the highest level This standard dynamic checkweigher is available in a large number of combinations including combi checkers with a metal detector. Or to be used with an end of line vision inspection system LabelSecure The CWEmaxx series dynamic checkweigher normally used in the food industry mainly in middle and high-performance settings. In the non-food area they are used in lines with high output and for weighing ranges of up to 15 kilograms. Alternatively if you are looking for more hygienic dynamic checkweighers then you may want to consider the CWPmaxx. A checkweigher that is perfectly suited to food processing where cleanliness and hygiene needs to be of the very highest standard. Furthermore if you are looking for a smaller unit, then you may want to look at the new CWD checkweighers. As a result this will weigh and check up to 250 items per minute. Also consider the other model in this range is the CWFMaxx. This...

Request for a quote

COGNEX CORPORATION

Germany

DSMax is the fastest and highest definition laser line 3D displacement sensor on the market for acquiring images and inspecting products in 3D. It is the only sensor that offers: — High scan rates (up to 18 kHz) at full measurement range — Maximum resolution images (2,000 profile points) — Fast high dynamic range (HDR) image These features make it the ideal solution for measuring and inspecting very small parts, such as electronic components, which can contain highly reflective or dark features.

Request for a quote

COGNEX CORPORATION

Germany

The 3D-A5000 offers a variety of fields of view and measurement ranges to accommodate applications in the automotive, consumer goods, and logistics industries. Other features and benefits include: — Patent-pending 3D LightBurst technology enables rapid image acquisition — More than 1.5 million 3D data points detect fine features on parts — High Dynamic Range (HDR) mode captures scenes with high contrast — Powerful 3D tools in VisionPro solve challenging 3D applications — Factory-calibration delivers results in real-world units — Rugged IP65-rated housing provides protection in harsh factory environments

Request for a quote

COGNEX CORPORATION

Germany

The In-Sight D900 is a smart camera powered by In-Sight ViDi software designed specifically to run deep learning applications. This embedded solution helps factory automation customers easily solve challenging industrial OCR, assembly verification, and random defect detection applications anywhere on the line that have gone uninspected because they are often too difficult to program with traditional, rule-based machine vision tools. In-Sight ViDi applications are deployed on the In-Sight D900 smart camera without the need for a PC, making deep learning technology accessible to non-programmers. It uses the familiar and easy-to-use In-Sight spreadsheet platform which simplifies application development and factory integration.

Request for a quote

COGNEX CORPORATION

Germany

The High Speed Steerable Mirror (HSSM) attached to the DataMan 470 fixed-mount barcode reader provides a high-performance, cost-effective solution for large field of view applications. Previously, pallet scanning, aggregation, and large area scanning functions required expensive, high-resolution PC-vision, or two or more smart cameras to successfully read the high volume and variation of barcodes. HSSM provides: — Greater coverage — 10x resolution — Faster installation and speed — Increased productivity The high accuracy HSSM transforms 3MP and 5MP barcode readers to an effective resolution greater than a 50MP sensor. This makes the mirror ideal for large field of view applications which often have shorter working distances and high variability like pharmaceutical aggregation and scanning pallets in logistics operations.

Request for a quote

COGNEX CORPORATION

Germany

In-Sight 2000 series vision sensors combine the power of an In-Sight vision system with the simplicity and affordability of a vision sensor. Ideal for solving error-proofing applications, these vision sensors set new standards for value, ease of use and flexibility thanks to a powerful combination of proven In-Sight vision tools, a simple setup, and a modular design featuring field-changeable lighting and optics. Together with the In-Sight Explorer EasyBuilder interface, which provides a fast, step-by-step application setup, these vision sensors allow even novice users to achieve extremely reliable inspection performance in nearly any production environment. In-Sight 2000 series vision sensors can also be configured for in-line and right-angle mounting installation. This modular body design provides maximum flexibility to mount in tight spaces, allows for customized wiring and optical paths, and minimizes the need to design new mechanical fixtures.

Request for a quote

COGNEX CORPORATION

Germany

The In-Sight 3D-L4000 is a breakthrough in three-dimensional (3D) vision technology. This unique vision system combines 3D laser displacement technology with a smart camera allowing factory engineers to quickly, accurately, and cost effectively solve a wide variety of inspections. The patented speckle-free blue laser optics, an industry first, acquires high quality 3D images and on-board high-performance processing powers a comprehensive set of true 3D vision tools, without the need for external processing. 3D vision tools are set up as easily as 2D vision tools thanks to the familiar and robust In-Sight spreadsheet environment. The intuitive In-Sight spreadsheet interface quickly and easily sets up and runs 3D applications without the need for programming. The In-Sight 3D-L4000 provides the capability to combine 2D and 3D vision tools in a single job to solve a wider variety of applications.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

COGNEX CORPORATION

Germany

The In-Sight 2800 vision system combines deep learning technology with traditional rule-based vision tools to solve a wide range of applications. From simple presence/absence detection to advanced categorization and sorting tasks, In-Sight 2800 provides an easy to deploy solution for error-proofing. Designed for factory automation, In-Sight 2800 enables manufacturers of all size to: — Increase product quality – Catch small, subtle defects with optimized error detection. — Maximize operational efficiency – Leverage your existing workforce and keep your lines running with fast, intuitive job setup. — Streamline integration – Take the guesswork out of image optimization and identify the correct combination of accessories in a few button clicks. Automate error detection in minutes – no experience required

Request for a quote

COGNEX CORPORATION

Germany

Machine vision tools and barcode reading systems produce a lot of insight-rich data across manufacturing and logistics facilities. The expansion of Industry 4.0 through the Industrial Internet of Things (IIoT) focuses on improving operations by collecting and analyzing data in an efficient way like at “the edge” of the production line as opposed to sending data to the cloud and back. The Cognex Edge Intelligence (EI) platform transforms big data into smart data and provides real-time system performance monitoring and device management to improve overall equipment effectiveness (OEE) and throughput. EI device setup is fast and simple for both new and existing automation lines, preventing downtime and boosting productivity for your operation. Easily connect to the EI platform through any web browser to start collecting data right away. Additionally, users can configure and manage several devices at once.

Request for a quote

COGNEX CORPORATION

Germany

VisionPro ViDi is the first deep learning-based image analysis software designed specifically for factory automation. Combining artificial intelligence (AI) with VisionPro and Cognex Designer Software, VisionPro ViDi solves complex applications that are too difficult, tedious, or expensive for traditional machine vision systems. This novel approach, which tolerates deviation and unpredictable defects, beats even the best quality inspectors and is ideal for: - Defect detection - Texture and material classification - Assembly verification and deformed part location - Character reading, including distorted print

Request for a quoteResults for

Vision systems - Import exportNumber of results

21 ProductsCompany type