- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- steaming

Results for

Steaming - Import export

BRÜCKNER TEXTILE TECHNOLOGIES GMBH & CO. KG

Germany

Compacting is the last finishing process after relaxation or drying and has thus decisive importance for the residual shrinking, the hand and the aspect and the shine of the fabric before cutting and makeup. The BRÜCKNER compacting calender is characterized by an extremely short fabric path, an optimum traction control and a sophisticated drive technology allowing high production speeds with consistent fabric quality. Depending on the fabric type and the quality requirements, BRÜCKNER can offer the following compacting solutions two felt belt compactors arranged one behind the other, rubber belt shrinking unit according to the Sanfor principle, rubber belt shrinking unit with downstream arranged felt belt compacting calender. In addition, the following units can be integrated into the compacting line equalizing frame for the overspreading and width control, straightener, steamer unit, edge cutter (knife or scissor type).

Request for a quote

IMM MASCHINENBAU GMBH

Germany

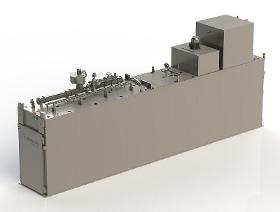

CNC polishing of compressor blades and vanes to optimize flow efficiency while at the same time minimizing differences due to tolerances in blade geometry. This is essential to the balancing of the compressor rotor and the fit of the stator parts. The SPE allows to keep up with the demand of this for the latest F-Class & H-Class Gas Turbine Compressors. The SPE CNC-Machine allows automatic polishing of all rows of the Gas Turbine Compressor, as well as most rows of Steam Turbine Blades within tight tolerances and highest repeatability. A dedicated CAD/CAM software allows for generation of NC part programs. As the SPE is a cartesian type machine tool there is no need for referencing or time consuming in process gauging. The precision and repeatability of the process allows the balancing of the milling process to leave a rougher scallop on the blade and save valuable time and cutter on the milling side. Capable of polishing compressor blades, fan blades and vanes up to 550 mm in length.

Request for a quote

FESSMANN GMBH UND CO KG

Germany

The TFi3000 Autovent is a true efficiencywonder! The patented procedure for lowpressure steam cooking without any fans at all, in combination with automated work processes, reduces the operating costs to a minimum. Cooling of the products in the closed system, directly subsequent to heat treatment, also ensures ideal hygiene conditions and increases durability. Production justintime, controllable process with reproducible work processes Automatic transport system Much lower germ formation and contamination – for longer durability Short cooking times and weight loss reduced by up to 15% Temperature difference across the system no more than 1 °C Uniform products at maximum quality due to turbulences and air velocities up to 200 m/s Very low maintenance and operation costs thanks to dispensing with fans Long service lives due to stainless steel construction and steamtight welding allround

Request for a quote

FESSMANN GMBH UND CO KG

Germany

The industrial system Ti3000 will get more than 1.5% more yield as compared to other systems at the tried and tested FESSMANN quality! Completely made of stainless steel and built steamtight out of panels, the Ti3000 is universally usable according to your specific needs. The central unit technology also convinces with its flexibility and best circulation air outputs at short process times.Panel construction and central unit technology for best air and process outputs Higher flexibility in implementation of customerspecific product requirements by smooth fan speeds Higher system capacities by faster process times = higher yield Use of all known supply trolleys for industrial use possible Use of "overlength" supply trolleys and transport frames Automatic door opener serially included Automatic CIP cleaning system serially included

Request for a quote

FESSMANN GMBH UND CO KG

Germany

The IKi3000 will always keep a cool head where efficiency and quality of your products are concerned. The cooling time reduction by up to 75% not only saves time and energy but also permits fastest passage through the critical temperature range for germ growth. It's a real improvement in hygiene and durability! Cooling times reduced by up to 75% Longer durability thanks to fastest passage through the critical temperature range for germ growth Less weight loss Less water consumption Additional steam cooking possible Optionally available with brine circuit Maximum flexibility thanks to construction kit system For processes with justintime production

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GUMMIWARENFABRIK EMIL SIMON GMBH & CO. KG

Germany

For use with saturated steam and hot water up to 90°C. Suitable for cleaning purposes. Steam hose 164 (+164°C/ 6 bar WP) or steam hose 210 (+210°C/ 18 bar WP) with 10 times bursting pressure safety. Also suitable for cleaning operations. Conforms to DIN EN ISO 6134. Construction: Black, electrically conductive EPDM tube Tension and pressure-resistant reinforcement inlays STEAM HOSE 164: Wrapped fabric inlays STEAM HOSE 210: Wrapped steel inlays Weather-resistant, electrically conductive, abrasion-resistant EPDM cover Interior and exterior smooth, fabric patterned *) Versions conforming to DIN EN ISO 6134. Versions with embedded steel wire on request. Other versions and dimensions on request.

Request for a quote

IMM MASCHINENBAU GMBH

Germany

CNC machine tool with 6 axis for belt grinding, polishing and belt linishing aircraft engine airfoils such as fan blades, vanes (OGVs and IGVs), steam turbine blades and gas turbine compressor blades and vanes. Extreme high precision and repeatable stock removal allows balancing of milling process to save milling time and cutter costs by maximizing milling roughness followed by MTS process.

Request for a quote

BÜRKLE GMBH

Germany

In contrast to conventional scoops, the stainless steel scoop has no openings, undercuts or crevices in which residues could collect. Pore-free finishing produced by high-quality laser welding seams. The stainless steel scoop can be flame-sterilised and can therefore be made completely germ-free.

Request for a quoteResults for

Steaming - Import exportNumber of results

9 ProductsCompany type