- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- stabilizers

Results for

Stabilizers - Import export

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

The core of the technology is the automated welding process, where the tank is simultaneously welded on the inside and the outside. Similar to the Lipp double fold technology the material will be pre formed by Lipp special forming machines and reinforcement ribs are applied for additional stability. By doing so, the wall thickness can be reduced which will have an economic effect on the overall material costs, without compromising structural stability. The process also enables the installation of roofs and other accessories at ground level, which reduces the risk of working at heights. The main application for the new Lipp welding technology is the drinking water sector. However, there is lots of market potential in the food and beverage industry, chemicals and pharmaceuticals as well as other industries. The black steel welding technology enables the installation of bulk silos with huge diameters and volumes, which is a significant improvement compared to today.

Request for a quote

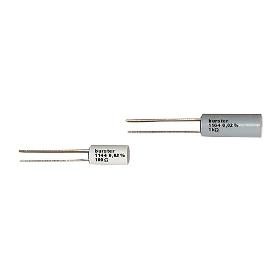

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Precision resistors are used wherever the highest standards of temperature stability, error tolerance and durability are required. Models 1164 and 1166 are available for higher loads up to 1 W. The resistors are supplied with two connections on the front end (suitable for mounting on circuit boards). The precision resistors comprise low-capacitance, low-inductance wire coils made of MANGANIN®, which are encapsulated in small plastic cylinder housings. Prior to trimming, the resistance bodies are exposed to a meticulous artificial aging procedure. This special process and trimming to approximately half of the nominal tolerance guarantee long-term stability of < 0.02% over the course of years. FEATURES: — TC ≤ 10 ppm/K —Class ± 0.02 % or ± 0.05 % —Production range from 5 Ω ... 100 kΩ —Resistance material MANGANIN® —Custom resistance values available on request —Minimum order per resistance value 10 pcs

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The 0.02 class calibration resistors excel in their modern design and small mechanical dimensions. Their ruggedness also ensures a long life. Calibration resistors of the 1240 series are used wherever very constant operating standards are required. Typical main areas of application therefore include: — When normal resistors prove to be too large scale — For test and calibration of resistance measurement devices — For tests on electrical temperature measuring equipment — For laboratory setup of a Wheatstone bridge — As shunt resistor for accurate current measurement — As part of standard equipment in research laboratories — For a large part of measurements in calibration laboratory. Features: — Range 10 μΩ ... 100 kΩ — Low capacitance and low inductance design — Suitable for direct current and technical frequencies — High stability < ± 0.01 % over years

Request for a quote

DATAPHYSICS INSTRUMENTS GMBH

Germany

The MultiScan MS 20 stability analysis system is a compact and versatile measuring instrument for the optical stability and ageing analysis of disperse multiphase mixtures, especially suspensions and emulsions. The MultiScan MS 20 enables non-destructive and temporally as well as spatially resolved optical stability and ageing analysis of emulsions, suspensions, and foams – undiluted and under realistic storage conditions. With sample chambers in discrete measurement towers – the ScanTowers – up to six measurements can be performed at the same time, covering different observation durations and different temperatures or temperature profiles. Measurements between -10°C and 80 °C are possible. The software then analyses and visualises the results, such as destabilisation mechanisms – sedimentation, creaming, or flocculation – and sample parameters such as particle size.

Request for a quote

BRÜCKNER TEXTILE TECHNOLOGIES GMBH & CO. KG

Germany

Finishing on a sanfor line provides the fabric with a more stable structure, a silklike shine, a smoother touch and minimum residual shrinkage. The rubberbelt compacting line is made for the sanforisation and compacting of woven fabric and some kinds of knitted fabric, in combination with a felt belt calender the fabric gets on these lines additionally a special touch. The benefits are among others optimum residual shrinkage due to the hightech drive concept, stabilisation of the fabric structure, silklike shine, soft fabric touch, absolutely constant shrinkage due to a new automatic shrinkage control system available as option, production speeds up to 100 m/min are possible, extended service life of the rubber belt due to the larger diameter of the compacting rollers and an optimised rubber belt cooling system, integrated menudriven rubber belt grinding process, minimisation of vibrations, all bearings arranged outside of the wet area and therefore no corrosion.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Stabilizers - Import exportNumber of results

5 ProductsCompany type