- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- spindle bearing

Results for

Spindle bearing - Import export

EWS WEIGELE GMBH & CO. KG

Germany

EWS quality now available for Swiss-type lathes. This new development in driven tools is EWS's response to many customers' requests. The tool systems may appear straightforward at first sight, but their simplicity belies their performance. The design concentrates on the mounting and the spindle concentricity. The requirement profile was developed jointly with an American medical technology company which uses very small drill bits and requires extreme concentricity properties. The spindle bearing technology used with labyrinth seals sets new standards in this field, and is associated with a long service life. Provision has already been made for service. The service centres in Germany, China, Korea and the USA have already been trained in the system and are ready to respond without delay. Third-party brands can also be serviced there at any time. Download catalogue: PDF

Request for a quote

MAGNESCALE EUROPE GMBH

Germany

Incremental length probe with magnetic detection principle. Very high accuracy and repeatability Extremely insensitive to contamination such as oil mist, moisture and dust Ball spline bearing of the spindle for long life time Perfectly suited for automated measured value acquisition in measuring devices, assembly and manufacturing lines

Request for a quote

MAGNESCALE EUROPE GMBH

Germany

Incremental length probe with magnetic detection principle for high reliability. with USB interface. Very high accuracy and repeatability.. Resolution 0,1µm or 0,5µm. Extremely insensitive to contamination such as oil mist, moisture and dust. Ball spline bearing of the spindle for long life time. Perfectly suited for automated measured value acquisition in measuring devices, assembly and manufacturing lines. Basic measuring software for evaluation included.

Request for a quote

MAGNESCALE EUROPE GMBH

Germany

Incremental length probe with magnetic detection principle for high reliability. with USB interface. Very high accuracy and repeatability. Resolution 0,1µm or 0,5µm Extremely insensitive to contamination such as oil mist, moisture and dust Ball spline bearing of the spindle for long life time Perfectly suited for automated measured value acquisition in measuring devices, assembly and manufacturing lines. Basic measuring software included

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

The ultraprecision turning machine (UP-Turning machine) MTC 650 is currently our largest series machine. Our customers can machine workpieces up to 200 kg in UP quality. The travelling distances are 400 mm in the Z-axis and 650 mm in the X-axis. Workpieces with a diameter of up to 800 mm in diameter (optionally 1000 mm) can be machined. The extended X travel offers more space for additional accessories, further tool holders or special bodies/ constructions. The MTC 6500 is based on a T-shaped natural granite bed. X- and Z-axis slides, as well as the housing of the main spindle are made of granite too. Both slides and the optional B-axis use hydrostatic (oil) bearings. The main spindle features an air bearing and is mounted to the X-slide. Different vacuum chucks for workpieces of up to 800 mm (31.5’’) in diameter are available.

Request for a quote

MAGNESCALE EUROPE GMBH

Germany

Incremental length probe with magnetic detection principle for high reliability. Very high accuracy and repeatability Extremely insensitive to contamination such as oil mist, moisture and dust Ball spline bearing of the spindle for long life time Perfectly suited for automated measured value acquisition in measuring devices, assembly and manufacturing lines

Request for a quote

MAGNESCALE EUROPE GMBH

Germany

Incremental length probe with magnetic detection principle for high reliability. Very high accuracy and repeatability Extremely insensitive to contamination such as oil mist, moisture and dust Ball spline bearing of the spindle for long life time Perfectly suited for automated measured value acquisition in measuring devices, assembly and manufacturing lines

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

In the basic version the MMC 5000 consists of a main X-axis featuring a linear air bearing (feed axis), a linear roller bearing Z-axis (infeed axis) and the milling spindle (air bearing) mounted on top of the Z-axis. The main application is face milling of optical and mechanical precision components. A Y-axis is available as an option. Another useful accessory is a second milling spindle, used perpendicular to the first one, thus allowing for the machining of two sides of a workpiece to perpendicularity in one setup. Accessories, like vacuum chucks, different milling spindles, touch probes for part thickness measurement, machine interferometers and other sensors for insitu measurement of workpiece shape and roughness, make the MMC 5000 machines an effective tool. In addition, various sensors are available for measuring of the workpiece geometry and surface quality during the manufacturing process.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

The MMC 600/900 is the basis for a series of machines that, via several accessories and options, can be fully customized to individual needs. In the basic version the machine consists of a main X-axis featuring a linear air bearing (feed axis), a linear roller bearing Z-axis (infeed axis) and the milling spindle (air bearing) mounted on top of the Z-axis. The main application is face milling of optical and mechanical precision components. Several accessories like a Y-axis, an A-axis and/or C-axis are available, thus expanding the range of machinable parts to microstructures, lenticular structures, spheres, polygons and so on. Accessories, like vacuum chucks, different milling spindles, touch probes for part thickness measurement and even machine interferometers for insitu measurement of workpiece shape, make the MMC 600 and 900 machines an effective tool. Besides further accessories, there is the possibility to make customized solutions, to adapt the machine to your needs.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

The ultraprecision turning machine (UP-Turning machine) MTC 400 (Micro Turning Center) is designed to hold heavy weight workpieces up to 100 kg. The travelling distances of the X- and Z-axis are 400 mm and provide the machining of workpieces up to 800 mm in diameter. The MTC 400 is based on a T-shaped natural granite bed. X- and Z-axis slides, as well as the housing of the main spindle are made of granite too. Both slides and the optional B-axis use hydrostatic (oil) bearings. The main spindle features an air bearing and is mounted to the X-slide. Different vacuum chucks for workpieces of up to 800 mm (31.5’’) in diameter are available. Besides many other accessories, that make the MTC 250 an all-purpose tool, there is the possibility to make customized solutions, to adapt the machine to your needs. Please do not hesitate to contact us.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

The ultraprecision turning machine (UP-Turning machine) MTC 350 (Micro Turning Center) combines dynamic use with an increased work space, thus resulting in a wide range of products to be manufactured. The travelling distances of the X- and Z-axis are 350 mm and provide the machining of workpieces up to 700 mm in diameter. The MTC 350 is based on a T-shaped natural granite bed. X- and Z-axis slides, as well as the housing of the main spindle are made of granite too. Both slides and the optional B-axis use hydrostatic (oil) bearings. The main spindle features an air bearing and is mounted to the X-slide. In addition to the X- and Z-axis there is the option to have an additional linear axis. This A-axis allows to do micro milling or raster flycutting operations on the machine. Besides many other accessories, that make the MTC 350 an all-purpose tool, there is the possibility to make customized solutions, to adapt the machine to your needs. Please do not hesitate to contact us.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

The ultraprecision turning machine (UP-Turning machine) MTC 250 (Micro Turning Center) has a lightweight construction of the moving parts and thus enables the machine axes to be used in a dynamic mode (Slow Tool). This machine is our standard machine with the smallest footprint. The travelling distances of the X- and Z-axis are 250 mm and provide the machining of workpieces up to 500 mm in diameter. The MTC 250 is based on a T-shaped natural granite bed. X- and Z-axis slides, as well as the housing of the main spindle are made of granite too. Both slides and the optional B-axis use hydrostatic (oil) bearings. The main spindle features an air bearing and is mounted to the X-slide. Besides many other accessories, that make the MTC 250 an all-purpose tool, there is the possibility to make customized solutions, to adapt the machine to your needs. Please do not hesitate to contact us.

Request for a quote

FISCHER FORTUNA GMBH

Germany

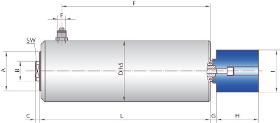

with hybrid spindle bearings and lifetime grease lubrication. Hybrid bearings with steelrings and ceramic balls ensure high lifetime and speed. The spindle is maintenance-free and requires no external service unit. The spindle nose air labyrinth seal reliably protects the bearings against the ingress of contamination and coolant. Spindles are not sold on the Webshop, but spindle inquiries are accepted. Below on this page are listed the available accessories for the HJN842 in the web shop.

Request for a quote

FISCHER FORTUNA GMBH

Germany

mit hybrid spindle bearings and lifetime grease lubrication. Hybrid bearings with steelrings and ceramic balls ensure high lifetime and speed. The spindle is maintenance-free and requires no external service unit. The spindle nose air labyrinth seal reliably protects the bearings against the ingress of contamination and coolant. Spindles are not sold on the Webshop, but spindle inquiries are accepted. Below on this page are listed the available accessories for the HJN860 in the web shop.

Request for a quote

FISCHER FORTUNA GMBH

Germany

with hybrid spindle bearings with lifetime grease lubrication. Hybrid bearings with steelrings and ceramic balls ensure high lifetime and speed. The spindle is maintenance-free and requires no external service unit. The spindle nose air labyrinth seal reliably protects the bearings against the ingress of contamination and coolant. Spindles are not sold on the Webshop, but spindle inquiries are accepted. Below on this page are listed the available accessories for the HJN828 in the web shop.

Request for a quote

APEX TOOL GROUP GMBH

Germany

Durable: • Hardened alloy steel cylinder and coated aluminum end plates reduce overall weight and extend life • Fan blade cooling system helps lower bearing and spindle temperatures, results in high durability and longer life Versatile: • Available in non-vacuum, central vacuum and self generating vacuum • 3”, 5” and 6” PSA and Hook & Loop pads available Ergonomic: • Recessed lever to eliminate any pinch points • Vibration absorbing comfort grip and ergonomic wrist support improves feel and increases maneuverability • Tool comes standard with 3” and 2 /34” grips • 360° rotating exhaust vanes help direct air away from operator • 360° rotating exhaust vanes • Fan blade cooling system

Request for a quote

BORRIES MARKIER-SYSTEME GMBH

Germany

The workshop unit 317 is a compact marker for permanent and flexible markings on almost all materials. Due to the ball bearing spindles and the carriage with circular ball track in both axes this model is very robust. The large marking area offers the opportunity to mark single or multi lines in free scalable dimensions. Angles and circular arcs, date, time and serial numbers are possible as well. Standard delivery is with LDM Macro software. Here, standard settings are printer or layout mode. Optionally VisuWin SE as well as VisuWin PRO PC software are available.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Easy manual actuation The TOROK manual chuck is primarily used in tool prototyping on machines without a clamping cylinder. For example, thanks to its easy manual actuation, when used on grinding machines you can safely and delicately clamp. In combination with our clamping device adaptations, such as the MANDO Adapt mandrel-in-chuck or the jaw module, many more clamping options are possible. Lightweight variant And most recent: Thanks to the optional lightweight CFRP design, with the TOROK CFK you save one-third the weight. This is particularly set-up friendly and it offloads the machine spindle bearings.

Request for a quoteResults for

Spindle bearing - Import exportNumber of results

19 ProductsCompany type