- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- sheet metal

Results for

Sheet metal - Import export

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

The high-performance automatic circular saws of the HCS-E series are specialists for highest cutting performance and premium quality, which quickly pay for themselves in multi-shift operation. The basis of the extreme performance is the unique, extremely stable and solid construction with perfectly matched components and state-of-the-art drive technology. The machine has a sturdy and robust base frame on which the combined sawing unit and material feed unit are mounted. This structure combined with a very robust machine design ensures a smooth sawing process with excellent cutting results and a long service-life of the saw blade. And what is remarkable: This system concept covers a large range of all industrial requirements, providing the highest quality at an unbeatable priceperformance ratio.

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

To address the most stringent demands in terms of cutting output, high precision, automation and process reliability BEHRINGER HBM series high-performance automatic bandsawing machines offer an impressive package of benefits, guaranteed not only by their vibration-damping structure made of grey cast iron components and the saw frame with its centric flow of forces. The sensitive BEHRINGER feed control also helps protect the saw blade, ensuring even greater economy through a long tool service life. By using a servo feed system, a high cutting performance is achieved when sawing tool and stainless steels and materials such as Hastelloy or Inconel with difficult machining properties. A highly efficient chip brush system cleans the saw blade on both sides from any adhering sawing chips.

Request for a quote

MECHASYS GMBH

Germany

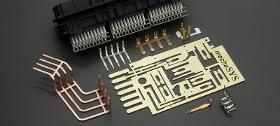

Laser cutting or laser fine cutting of metal, we can precisely process all metallic, non-toxic materials in material thicknesses from 0.2 to 2.0 mm. With our high-precision 1kW fiber laser (Nd: YAG with a wavelength of 1064nm) in combination with highly dynamic linear drives, we can produce your laser cuts in copper and brass. Due to our extremely small focus of 0.05mm, we usually create a cutting cag/ clearance of 0.07mm, so that the most delicate contours (especially inner contours) can be realized without mechanical stress, as the processing takes place without contact. This enables high-quality and precise prototypes and small series in contract manufacturing using cutting lasers. Accuracies of +/- 0.01mm, which are required in the sealing area for plastic overmolding for complete plugs or housings. Dimensions: sheet thicknesses from 0.2 to 2.0mm, max. sheet metal of max. 1,250mm x 1,250mm.

Request for a quote

ARNOLD UMFORMTECHNIK GMBH & CO. KG

Germany

The Flowform® screw is a polygonal screw based on TAPTITE 2000®, which makes use of the technology known as "flowhole-forming" in manufacturing processes. Using this technology the Flowform® screw causes the sheet metal to heat, using a combination of axial force and relatively high screwdriver speed . Once the material has been penetrated the polygonal shape of the screw forms a calibrated metric female thread which can accept a metric screw in the event that a repair is required. After the torque-controlled assembly process the formed through-hole adjusts optimally to the contours of the screw. This gives the following advantages: Higher process reliability in the screw fastening with the option of a larger screwdriver shut-off window More flexibility when selecting the screwdriver, and more straightforward monitoring of the assembly process. In addition the Flowform® screw considerably reduces screw-in times.

Request for a quote

ZOLLER & FRÖHLICH GMBH

Germany

Our metalworking shop allows us to realize customized housings according to customer requests. A team of experienced employees assures the necessary precision including all required cutouts and drillings of housings. Our own tool shop is equipped with machines for lathing, milling, electrical discharge machining and grinding which allow us to quickly manufacture customized parts/adjustments in-house.

Request for a quote

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

FX lifting magnets in universal design convince by their wide field of application. The FX achieves good results with large air gaps as well as with thin flat and round materials with a compact design and low dead weight. The device is characterized by great robustness and a very good price/performance ratio. First choice for all users who want to move massive sheets and blocks.

Request for a quote

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

SWR magnetic clamping brackets are switchable, precise devices that meet the highest quality requirements. Each leg can be switched separately and the holding force can be infinitely adjusted for positioning. The prismatic ground underside enables work to be carried out on flat and round material. SWR is available in the following versions: SWR 150, angular adjustment locking at 30,45,90,120,150,180° or free via locking screw. SWR 180, angle adjustment 45°-225°.

Request for a quote

ANDRITZ KAISER GMBH

Germany

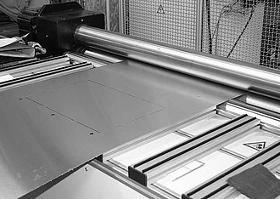

ANDRITZ Kaiser is among the most experienced suppliers of presses and automation for sheet metal forming on the market. High precision, long lifetime of machine and tool, and low maintenance costs speak for the quality of our machines. ANDRITZ Kaiser produces customized solutions for every application – from the stand-alone press or roll feeder to complete production lines with coil handling equipment, finished part handling, scrap handling, and automation system. With over 8,000 automatic punching and metal forming presses worldwide, our customers produce high-quality formed and punched products. Our sheet metal forming solutions find applications in the automotive (OEMs and suppliers), white goods, electronics, electromotor lamination, construction, and consumer goods industries. Numerous well-known companies place their trust in our equipment. Our range of products Complete production lines for blank cutting, electromotor lamination, or conventional stamping Automatic...

Request for a quote

MECHASYS GMBH

Germany

Do you have the idea for a new product, but don't know how you should or can implement it? We gladly support you! If you wish, let us sign a mutual nondisclosure agreement (NDA). Then we can speak openly, exchange ideas in mutual interest and together create the best possible design and the associated processes. You can see some of the products that have been implemented on the following pages. For example, modular punched cable shoes, press-fit areas in customer-specific hole spacing of the circuit board or punch feed. Or do you have the problem that you can only present handwritten sketches and no CAD data suitable for production? We can support you here too. Our team will be happy to advise you and design for you.

Request for a quote

SCHOCK GROUP

Germany

SCHOCK offers complete metal assembly systems with integrated functional components such as soft-close mechanisms, adjustment mechanisms, and mounting systems. The SCHOCK High Cabinet Full Extension, measuring 600mm in length and designed for installation in wooden cabinets with a load capacity of up to 120 kg, is available as a ready-to-install assembly: Full extension, length 600 mm Load capacity of up to 120 kg Guided both at the bottom and top Mounting brackets with front adjustment Soft-closing self-retraction with a 50 mm movement in the lower and upper guides Set packaging – pre-assembled and includes installation instructions We are also happy to manufacture other assemblies upon request according to your specifications. Length: 600 mm Load capacity: up to 120 kg Comfort features: Soft-closing self-retraction

Request for a quote

SIMPAC EUROPE GMBH

Germany

Compact presses for a wide range of medium sized parts. Due to its drive-related slide kinematics, the MCL series is particularly suitable for drawn parts. Overview: ● Pressing capacity: 3,000 - 8,000 kN ● Component size: medium ● Slide kinematics: link ● Applications: stamping, drawing, forming Features and benefits: ● The compact design requires little floor space and no foundation at presses below 4,000 kN. ● The very solid, low-stress annealed press bodies are FEM-calculated and optimized by so-called “hot-spot analysis” in areas which are subject to higher loads. ● Motor, clutch/brake unit, lubrication system and control are of German origin and guarantee a long service life and maximum dynamics. ● The slide guiding system ensures a high level of tilting rigidity and reduces the cutting impact during the cut through when it comes to the processing of higher-strength materials.

Request for a quote

SIMPAC EUROPE GMBH

Germany

Compact and modular presses for a wide range of medium sized parts. Flexible installation options as a single press in progressive or transfer mode or as fully automated press line. Overview: ● Pressing capacity: 3,000 - 10,000 kN ● Component size: medium ● Slide kinematics: crank ● Applications: stamping, cutting, forming, bending, embossing Features and benefits: ● The compact design requires little floor space and no foundation at presses below 4,000 kN. ● The very solid, low-stress annealed press bodies are FEM-calculated and optimized by so-called “hot-spot analysis” in areas which are subject to higher loads. ● Motor, clutch/brake unit, lubrication system and control are of German origin and guarantee a long service life and maximum dynamics. ● The slide guiding system ensures a high level of tilting rigidity and reduces the cutting impact during the cut through when it comes to the processing of higher-strength materials.

Request for a quote

SIMPAC EUROPE GMBH

Germany

The Scotch-Yoke drive of the DTL series has a modified link drive characteristic and reduces the slide speed during the forming phase. Thus the presses are not only suitable for cutting, punching and forming tasks, but also for drawing operations. The extra time that the material receives for plastic flow significantly increases the quality of the produced parts. The reduced impact speed of the slide extends the life of the press and the die. Overview: ● Press capacity: 6,000 - 30,000 kN ● Part size: large ● Slide kinematics: link ● Application: as a single press system either as progdie or transfer mode, as well as a press line Description and benefits: ● The outside located pressure points and a long 8-fold slide guiding system well compensate off-center loads, spare press and die and ensure a constant part quality. ● The automatic centralized lubrication system increases pro-ductivity and availability.

Request for a quote

SIMPAC EUROPE GMBH

Germany

The eccentric drive of the DTE series is primarily suited for cutting, blanking, forming and embossing operations. Its characteristic sinusoidal slide motion curve makes it ideal for flat and semi-flat parts. The proven and continuously optimized technology ensures reliable production processes. Overview: ● Type: Eccentric presses ● Press capacity: 8,000 - 25,000 kN ● Part size: large ● Slide kinematics: crank / eccentric motion ● Application: as a single press system either as progdie or transfer mode, as well as a press line Features and benefits: ● High part quality due to rigid, FEM-optimized press design ● The outside located pressure points and a long 8-fold slide guiding system absorbe off-center loads, spare press and die and ensure a constant part quality ● Extensive range of optional equipment, such as die cushions, pneumatic ejectors or moving bolsters for a faster die change

Request for a quote

ARNOLD UMFORMTECHNIK GMBH & CO. KG

Germany

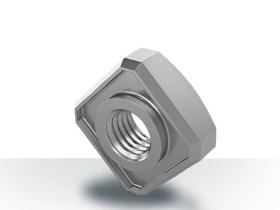

With PIAS® pierce-clinch nuts (square) and RIVTEX® (ROUND) a non-detachable metal fastening can be created at optimum cost. The pierce-clinching technology is suitable for steel and aluminium sheets, causes very little cost for inspection and control, and allows several pierce-clinch screws to be processed in a single stroke. PIAS® and RIVTEX® pierce-clinch nuts offer the following advantages over welded nuts: corrosion-resistant no weld spatter on the thread no thermal weakening at the fastening position self-piercing higher torque requirements high process reliability in fully-automated processing flush-mounted processing processing can be manual, semi or fully automated self-locking thread possible

Request for a quote

ARNOLD UMFORMTECHNIK GMBH & CO. KG

Germany

The future is lightweight – with Flexweld®. Flexweld®, the unique joining process, offers countless benefits, with one of the biggest advantages being the considerable weight reduction in the age of lightweight construction. Moreover, no additional machinery is required to incorporate it into an existing car body assembly line. significant weight saving, which provides long-term reduction in CO2 emissions joins lightweight materials to high-strength metals can be incorporated into existing assembly lines since it is possible to use the same production and welding equipment no additional qualification for workers needed complete system including full feeder and processing technology mixed production possible by adapting the spot weld gun software

Request for a quote

ARNOLD UMFORMTECHNIK GMBH & CO. KG

Germany

Using Sheetite® ensures that in metal-joining applications, you can eliminate work processes such as thread tapping, and also dispense with additional fastening elements. The fastener is screwed directly into a metal rim-hole or a pre-drilled metal sheet, using existing plant and equipment. The polygon-shaped cross-section geometry in the thread-tapping section of screw's shaft ensures that the thread is chiplessly formed, so that if a repair is needed it can accept a conventional threaded screw. reliable low cost flexible easy to assemble very stable reduces number of variants

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Sheet metal - Import exportNumber of results

22 ProductsCompany type