- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- positioning table

Results for

Positioning table - Import export

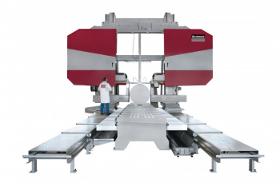

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

In forging mills, rolling and gravity die-casting foundries, and steel finishing works, these machines provide the ideal answer for dealing with large dimensions. They are perfect for preproduction in tool and mold making factories, helping to save valuable milling time. The material support table is recessed in the foundation. Its low-level transition to the hall floor makes for simpler material handling. The moving saw frame can be positioned by axis control precisely at the point of cutting. Where no sawing is taking place, the table is freely accessible. This also allows space for a second piece of material to be loaded while the saw is cutting. This system helps reduce downtime between cuts and enhances productivity. Benefits of the Gantry Machines - Space-saving installation - Durable material support table - Simple positioning of the saw frame - Optional: blade guide with 90° rotation facility for vertical and horizontal sawing to allow notching of materials

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

Their flexibility and high performance make BEHRINGER tabletop machines the ideal solution for the medium ton range. The table moves the weight BEHRINGER tabletop machines are ideal for use in forges, rolling mills and die casting factories, in steel finishing works and for tool and mold making. Their individually traversable material clamping vices and blade guide arms make these ideal for cutting bulky materials. The low table height makes this type of machine ideally suited for use on normal hall floor level. BEHRINGER tabletop machines are supplied as standard in semi-automatic form. Automation is possible by upgrading with an additional material clamping vice at the end of the table. Positioning takes place on an axiscontrolled basis. Optionally available is 90° rotatable blade guide for vertical and horizontal sawing to allow notching of materials.

Request for a quote

DATAPHYSICS INSTRUMENTS GMBH

Germany

The optical contact angle meters of the OCA series are high-precision measuring systems for the characterisation of interfaces and surfaces. They combine high-resolution optics, pinpoint liquid dosing and precise sample positioning to create powerful, reliable measuring systems. The OCA 25 standard model is the all-purpose system for contact angle measurements and drop shape analysis. The high-performance camera makes it possible to measure contact angles even on adsorbent surfaces such as tissues or powders. Compared to the entry-level OCA 15, additional measurements at temperatures of up to 700 °C are possible. Further advantages are the more precise positioning of the sample table as well as the compatibility with many more dosing systems, which allow electronic dosing and droplet volumes down to a minimum of ten nanolitres. Measurements: - static contact angle - dynamic contact angle - interfacial/surface tension - surface energy - viscoelastic modulus - work of adhesion

Request for a quote

HERMA GMBH

Germany

Uncompromisingly fast and reliably effective Primarily designed for round pharmaceutical products, such as glass vials and the corresponding high batch sizes in the healthcare industry Wrap-around labeler 132M HC for healthcare products with a high-speed output of up to 400 products per minute High labeling speed with extreme precision thanks to the new HERMA 500, our high-performance applicator It is completely equipped for all healthcare tasks, including a selection of various printing and control systems, an patented automatic label return with cross check, as well as one of several possible product reject stations New innovative HERMA rotary tables, electronic position indicators and format sets that can be exchanged without tools for fast format changes ensure maximum overall equipment effectiveness The 132M HC can be easily configured for numerous industry applications - even without printers and control systems in the version 132M

Request for a quote

ASSFALG GMBH

Germany

Whether while milling (rough and finish machining), drilling, sawing, welding or assembling, the EPM modules or module systems offer a large selection of clamping options, for example, to clamp during edge milling or deburring (without mechanical clamping equipment) or for the simple and quick fastening of workpieces during assembly. Workpieces can be easily and quickly fastened with the Triplemag magnet clamping elements. The Triplemag series has additional positioning magnets, ensuring a constant position on the machine table and which are separately switched. Through the use of pole extensions, any unevenness on the workpiece can be compensated for and a deformation of the workpiece can be prevented. Using pole extensions, plane-parallelism of up to 0.01 mm is possible on the workpiece. The processing runs without vibration and an even distribution of holding force is guaranteed throughout the entire ferrous clamping surface.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Positioning table - Import exportNumber of results

5 ProductsCompany type