- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- packaging lines

Results for

Packaging lines - Import export

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

Hugo Beck can claim a decade-long development tradition when it comes to automation. We offer support with our expertise throughout the entire automation process, from project planning and manufacture right through to integration into complex packaging lines. Handling systems such as portals, grouping solutions, stacking and counting devices, cross pusher to name but a few, are integrated reliably into the packaging solutions by our technicians. Furthermore, various robots systems are used across many industries for the automated feeding of products, helping to for example grip, position, stack, group, stage products. From a parallel robot (also known as a spider robot) all the way through to a SCARA robot – anything is flexibly possible and delivered fully integrated according to each customer‘s needs. Both robots and handling systems can all be purchased independently of Hugo Beck packaging machines.

Request for a quote

BALLERSTAEDT & CO. OHG

Germany

Flat aluminium seals are mainly used in the cosmetic, pharmaceuticals and food industries. They are applied using fully automatic packaging lines (e.g. BaCo 2500 and BaCo 3600). The aluminium seals are available in any shape, size, material specification and design. Advantages Quality protection Protection against light, oxygen, germs, water vapour and foreign odours Tamper proof Absolute tightness Exclusivity through individual print and decoration Easy to peel off Residue-free removal Pasteurisable, sterilisable and breathable seals

Request for a quote

BALLERSTAEDT & CO. OHG

Germany

Material on reels is the alternative to punched platelets and is used in packaging production lines with "inline" punching. The features are identical to the pre-punched seals. We offer various qualities, which can be used for conductive or inductive sealing, e.g. of paste tubes, in an inline process.

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP A 075/Ri Forming Machine for DIP Components Description The Streckfuss forming machine type A 075 Ri is designed to form the leads of dual in- line package components utilizing a tube- to- tube feeding configuration. The machine is able to process DIP's in a wide range of component sizes (from 7,62 mm up to 19,9 mm). The adjustment of lead span can be preset and is displayed on a digital panel. The supply of components can only be done by the use of component tubes. The processing speed is continuously variable. Up to 5.000 components can be processed within an hour. Components

Request for a quote

OPTIMA LIFE SCIENCE GMBH

Germany

Technical Data: Output: up to 1,200 products/min (multi lane, single lane solutions available) Web speed: up to 70 m/min Web width: max. 320 mm (special widths on request) Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields.

Do you sell or make similar products?

Sign up to europages and have your products listed

OPTIMA LIFE SCIENCE GMBH

Germany

Production lines for medical products, especially for wound care products The web tension and cutting behaviour of complex wound dressings can often be challenging. Combining long-standing experience with innovative technologies – thus creating a whole new approach - is vital for such applications. It is not by chance that Optima Life Science has become an established trend- setter on the market: To get the best possible results, Optima Life Science implements tests in its own development department, placing top priority on gentle product handling, output and cutting precision. Products: Wound dressings (i. e. film, foam, hydrocolloid, hydrogel) Plasters Antimicrobial Dressings Test patches for allergies Diagnostic test strips Post OP Dressings Please contact us if your requirements are beyond the technical data limits. We are specialists in developing customised solutions.

OPTIMA LIFE SCIENCE GMBH

Germany

Features Modularity: Quick change and addition of modules Scalability: Machine can be extended from an entry level machine to a fully-automated production line Service: Spare parts, online remote service, scheduled maintenance, upgrades, repairs, process optimization Quality: Professional production equipment suitable for 24/7 operation Documentation: Machines delivered with all significant guidelines (CE etc.) Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields.

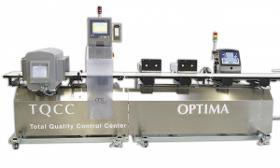

OPTIMA NONWOVENS GMBH

Germany

Metal detection based on measurement of magnetic permeability Check-weighing process with industrial load cells Rejection pushers mounted on a separated frame to avoid any vibrations 5 separate servo driven belts Interface between TQCC and bagger included One HMI for metal detector, check-weigher and rejection Modular design for easy service

OPTIMA CONSUMER GMBH

Germany

A partnership that offers you entirely new opportunities. HÖRAUF is an expert in producing equipment to convert paperboard and composite material to packaging cans. OPTIMA is an expert in dosing and filling of a wide variety of products. Together with certified material suppliers you are able to produce your individually shaped packaging in-line, in perfect quality. Further information: www.inlinecan.com

OPTIMA NONWOVENS GMBH

Germany

The OPTIMA WWM loads pre-packed wet wipes into PE bags. The machine concept is based on the LBV series which can be found in most of the countries around the globe. Packaging of paper hygienic products asks for minimum volumes at maximum speeds. From standard machines to high-performance packaging lines, machines from Optima Nonwovens are modular in construction and allowing to implement your special requirements. Secondary packaging of pre-packed wet wipes Handling of up to 4 rows possible Quick and easy change-over Cross direction feeding of pre-packed wet wipes

Results for

Packaging lines - Import exportNumber of results

11 ProductsCompany type

Category

- Packing and packaging - machinery and equipment (2)

- Chemical and pharmaceutical industry - machinery and equipment (2)

- Package stamping machinery (2)

- Paper and cardboard manufacturing - machinery and equipment (2)

- Sealing and wrapping - machinery and equipment (1)

- Pharmaceutical industry - machinery and equipment (1)