- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- mouldings

Results for

Mouldings - Import export

A.H. LEHMANN BLECHWARENFABRIK GMBH

Germany

Trouble-free baking and consistently perfect stollen with our deep-drawn stollen moulds. Set: aluminized 0.75 - 0.88 mm back darked Lid: aluminized 1.25 mm Our mould-sets with external dimensions of 580 mm are also deally suitable for the baking trolley.

Request for a quote

A.H. LEHMANN BLECHWARENFABRIK GMBH

Germany

Moulds: Trays for Muffins Trays with raised Moulds for "Mohrenkopf" Trays for small Gugelhopf Moulds with and without tube Trays for Madeleines Trays for Torteletts Trays with hemisphere Moulds Trays for "Twinkies" Trays for "Florentiner" Trays for Little Tarts Trays for Little Ribbed Plaited Loafs Trays for Tartlets

Request for a quote

A.H. LEHMANN BLECHWARENFABRIK GMBH

Germany

Madeira Cake Mould Set deep-drawn, Set 5-strap special for madeira cake Easter Egg Mould Set 3 egg moulds suitable for all pastes Plaited Loaf Mould für Hefezopf und Rührkuchen Heart Mould Set 3-strap with convexed bottom Bell Mould Set 3-strap Marguerite Mould decorative flower shaped mould for sponge- and angel cake Stollen Mould oval mould with corrugated border

Request for a quote

A.H. LEHMANN BLECHWARENFABRIK GMBH

Germany

Material: sheet steel with silicon coating Proficoat 100 Tins: deep-drawn Sets: with adjacented frame Scallop-edged Cake Tins: "Dom-Cake" "Strong" Scallop-edged Cake Tin Set half round Other special individual tin sizes and frame versions can also be produced for larger order quantities, and provided in case the relevant tooling is available.

Request for a quote

A.H. LEHMANN BLECHWARENFABRIK GMBH

Germany

All tart rings and cutters are made exclusively of stainless steel 1.4301. Small Tart Rings & Cutters: round, hexagon, rhombus, oval, acute-oval shaped

Request for a quote

A.H. LEHMANN BLECHWARENFABRIK GMBH

Germany

Standard-Sizes Diameter 160 - 300 mm in different height. Cake Rings: aluminium, stainless steel, stainless steel adjustable Cake Ringsoctagonal, oval and heard shaped, Florentine Rings "Cobble stone" Glady we supply also special sizes.

Request for a quote

A.H. LEHMANN BLECHWARENFABRIK GMBH

Germany

Robust design with recessed or plane bottom with ribbed or smooth border. Type in: blue-plate with "Proficoat 100" aluminized, aluminium and stainless steel 1.4301 They are qualified for: Fruit Flan Tins Mini Flan Tin Flan Case Cake Plate Cream-Cake Mould half-round

Request for a quote

A.H. LEHMANN BLECHWARENFABRIK GMBH

Germany

With smooth, rolled border: robust design blue-plate 0.70 mm blue-plate with "Proficoat 100"or "Provicoat 300" coated or aluminium 1.2 mm They are qualified for: Fruit Tart- andChese Cake Tins Cake Tin "Classic" Pizza Tins Do you have any special requirements? We can produce virtually any size for you. Simply give us call for further information.

Request for a quote

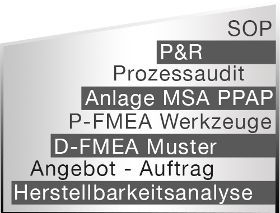

MECHASYS GMBH

Germany

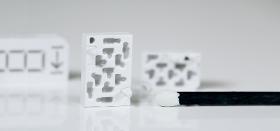

In terms of project management, the respective feasibility study is a matter of course. No offer without a feasibility study. -An offer implies manufacturability; this is how our process is defined! - We live from prototypes and small series. Often there is no second assignment, so there shouldn't be any unforeseen surprises. Or at least only within a manageable framework. The combination of metal and plastic composite parts makes this a challenge from time to time. But you can be sure that here we draw on a wealth of experience that we would like to share with you.

Request for a quote

SCHOCK GROUP

Germany

SCHOCK manufactures sophisticated 1- and 2-component plastic parts with modern machinery. Our competences also include the corresponding mold and tool design.

Request for a quote

KRAMSKI GMBH

Germany

Our development team works in cooperation with our project management department and engineering department by providing customized research and development. They take into account the fulfillment of the product requirements, as well as the perfect matching of the product to its subsequent manufacturing process. Through the early participation of our development team and the early implementation of their ideas during product development, our customers can save significantly.

Request for a quote

KRAMSKI GMBH

Germany

The testing of a new design or process with maximized series-ready specifications – that is the job of our prototyping department. In close cooperation with our customers, we create a sample perfectly matched to the given framework. In addition to our own technologies, we can also integrate processes from our partners (e.g. electroplating or laser processing).

Request for a quote

KRAMSKI GMBH

Germany

Compositing of stamped metal insert parts and plastic belongs to our core skills. With our know-how in both technologies, we are able to offer our customers projects and production that push the borders of what is technically possible, when synergistically compositing metal and plastic – and that from us as a single source.

Request for a quote

KRAMSKI GMBH

Germany

In stamping technology, many very different technologies can be integrated into the stamping process, such as assembling two or more parts, contact riveting, resistance and laser welding, laser marking of parts, or thread forming. Our high-precision tools, thereby, create a basis for production that is, over its lifetime, very high quality and economical. The stamping process is accompanied by a 100 % quality control of the functional design dimensions.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KRAMSKI GMBH

Germany

Our core technologies, precision stamping and hybrid technology, are complemented by our special processes (parts cleaning, tumbling, brushing, sand blasting, polishing, laser marking, tape-and-reel, and more). Here, it is all about know-how-intensive processes and work steps, which we specifically use to improve the quality of our products and to hold our promise of KRAMSKI quality in every way.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

LT Ultra is your partner for the production of optical surface qualities in injection mold inserts. For example, we can manufacture inserts for the injection molding of spectacle lenses with several focal lengths as well as mold inserts for microlenses or components for vehicle lighting systems. In addition to simple geometries such as spheres or aspheres, we mainly manufacture non-rotationally symmetrical components and freeform surfaces.Mold inserts for a long service life can be made from chemically deposited nickel (NiP). Here you can work directly in the nickel. The advantage is that the very durable nickel can also be deposited on substrates that could not be brought into optical quality themselves or only with great effort. On request, LT Ultra offers the complete delivery of the mold insert as well as the processing of additional parts.

Request for a quote

PRESSTECK S.P.A.

Germany

Deep drawn cylindrical battery housings made of nickel plated steel Various standard sizes of cylindrical battery housings for edrive applications like 21700, 46800

Request for a quote

PRESSTECK S.P.A.

Germany

We are experts in deep-drawn parts made of stainless steel, deep-drawn parts made of aluminium and other non-ferrous metals (including brass, copper and nickel silver). To produce your perfect component, we also have the option of using carbon steel, special nickel alloys (e.g. Inconel®), but also soft magnetic materials. Each material has specific properties that need to be taken into account in the forming process. We manufacture deep-drawn parts with a diameter of 2 to 80 mm and a length of up to 120 mm. We process material thicknesses from 0.05 to 2.50 mm. Pharmaceuticals and medical technology, industry, consumer and automotive: we are primarily active in these fast-growing sectors. We are not only specialists in deep drawing, but also know the industrial requirements and process chains. Depending on your requirements, we complement deep-drawing with numerous secondary finishing processes up to fully automated assembly systems.

Request for a quote

PRESSTECK S.P.A.

Germany

You don't need deep-drawn individual parts, but complex assemblies already assembled? We are your experts for that! First we analyse your requirements for new potentials. Combined with innovative thinking and agile processes, we then design smart solutions with you to manufacture your desired assemblies. Depending on your requirements, we develop decoupled, partially or fully interlinked assembly processes using high-performance systems and state-of-the-art equipment. We reliably ensure your quality requirements with integrated and individual testing measures.

Request for a quote

PRESSTECK S.P.A.

Germany

We are experts in deep-drawn parts made of stainless steel, deep-drawn parts made of aluminium and other non-ferrous metals (including brass, copper and nickel silver). To produce your perfect component, we also have the option of using carbon steel, special nickel alloys (e.g. Inconel®), but also soft magnetic materials. Each material has specific properties that need to be taken into account in the forming process. We manufacture deep-drawn parts with a diameter of 2 to 80 mm and a length of up to 120 mm. We process material thicknesses from 0.05 to 2.50 mm.Pharmaceutical and medical technology, industry, consumer and automotive: we are primarily active in these fast-growing sectors. We are not only specialists in deep drawing, but also know the industrial requirements and process chains. Depending on your requirements, we complement deep-drawing with numerous secondary finishing processes up to fully automated assembly systems.

Request for a quote

PRESSTECK S.P.A.

Germany

Pressteck is one of the world's leading specialists for deep-drawn individual parts on transfer presses and their processing into assemblies. In this non-cutting tension-pressure process, we produce hollow parts from a metal strip in several stages, which can be aluminium, stainless steel, copper or brass, among others. Compared to other processes, deep drawing has decisive advantages: Material consumption and production costs are lower, and at the same time the strength of the components is higher. We are highly innovative and optimise deep drawing technology beyond what is currently possible. We manufacture your individual component from coiled sheet metal and master demanding geometries and high degrees of forming.

Request for a quote

PRESSTECK S.P.A.

Germany

Thermostatic valves - i.e. the temperature controls on the heating system - are found in just about every home. In the head of a thermostatic valve there is a metal bellows, a corrugated tube that expands according to the room air temperature. For these metal bellows, the manufacturer needed deep-drawn, very long and thin-walled sleeves. The challenge: the sleeves must be matched to the customer's downstream process under very tight tolerance specifications. Why? Because the sleeves cannot be further processed if the geometries vary. Absolute precision is therefore required. We can offer absolute precision. The customer commissioned us with the production of the sleeves. On the one hand, because we fulfil the special deep-drawing requirements. On the other hand, because we can offer an associated, targeted heat treatment for material stress relief in-house.

Request for a quote

PRESSTECK S.P.A.

Germany

For our customers in the automotive and housing industry, we produce deep-drawn stainless steel pots with an integrated axle as a monobloc component. These are used in water pumps for electric vehicles. Our customer from the automotive industry needs pots with an integrated axle that holds a rotor. Up to now, the pot and axle have been joined in a centred manner by means of welding. The customer's wish was to produce a one-piece component to avoid welding. Deep drawing is the ideal technology for this. The size of the component required larger presses than were previously available. Therefore, we first developed tools as prototypes for larger presses on behalf of the customer. After practical tests at the customer's premises as well as at the end customer's, our client decided on a tool that was ideally suited for the production of the component in series.

Request for a quote

PRESSTECK S.P.A.

Germany

Support sleeves for reinforcing plastic components. Made of stainless steel with customised design. The bushings can be produced not only round but also oval as a deep-drawn part.

Request for a quote

SCHOCK GROUP

Germany

Your project is in the best hands at SCHOCK. Our experienced engineers use state-of-the-art methods to plan all resources and guarantee on-time production. In addition, we supervise your tool over its entire life cycle. In mold and tool making, we work with high-quality milling machines, wire and die-sinking EDM machines, and modern CNC-controlled grinding machines.

Request for a quote

KUNSTSTOFFTECHNIK SCHMID GMBH & CO. KG

Germany

Customers from a wide range of industries rely on technically sophisticated injection-moulded parts made with up to three components. Our unique strength lies in the areas of multi-component technology, thermoplastics processing, elastomers and high-performance plastics.

Request for a quoteResults for

Mouldings - Import exportNumber of results

38 ProductsCompany type