- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- load testing

Results for

Load testing - Import export

ETH MESSTECHNIK GMBH

Germany

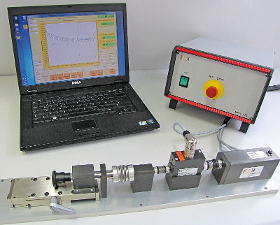

Customized Solution Spring brake - Seat adjustment slip clutch Left and right torque control Test samples on mounting carriage compact, slim design Constant load independent test speed selectable rotation direction and speed additional storage for the elimination of lateral forces quick change by magnetic holder

Request for a quote

ETH MESSTECHNIK GMBH

Germany

Mobile test device for detection of the maximum torque (drag indicator mode) and for the detection of the power range (constant load) of motors in dental and dental surgical application area. arbitrary loading curves endurance test speed measurement in aluminum case permanently installed Calibration disc and calibration will be in the trunk.

Request for a quote

ETH MESSTECHNIK GMBH

Germany

Customized Solution Hand-held device with integrated torque transducer. Direct channel selection of filed test programs. Drive of the transmission is achieved to the predetermined moment of friction during the assembly. Subsequent break-in period and subsequent Reibwertprüfung with threshold monitoring, visual evaluation and documentation. Direct channel selection of filed test programs Safety circuit by two-hand operation Constant load independent test speed either vertically or horizontally about Balancer

Request for a quote

ETH MESSTECHNIK GMBH

Germany

DPFR-004 Customized Solution for friction measurement of transmission A hand-held enclosure with integrated torque transducer, start buttons and 1 display for torque andf speed. Is used to the friction torque of tapered roller bearing set or monitor. portable Safety circuit by two-hand operation Constant load independent test speed

Request for a quote

ETH MESSTECHNIK GMBH

Germany

Friction measurement on gear with cam recording with service case In order to reduce the frictional torque in a gearbox from the automotive industry, a measuring device that accompanies the development is required. With the DPFR-027, changes in the design can be measured directly on the product. This means that even the smallest improvements can be determined. The field of application of this test device is extremely diverse and can be easily converted to other applications. Thanks to the mobile design, tests can be carried out under different temperatures and climatic conditions. hand-held drive unit compact slim design constant load-independent test speed selectable direction of rotation and speed additional storage to eliminate lateral forces Acquisition of torque and angle of rotation Graphic recording of the test sequence Storage of the test results in Excel

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WEINLICH GMBH & CO. KG

Germany

Two kinds of fuel are changed in the engine repeatedly without mixing. Thus also small differences in the specific consumption, the emissions and further values measured at the engine which are influenced by the fuel will be clearly visible. The engine is charged by a coupled braking dynamometer (engine test bed). At the test bed, different load conditions may be adjusted. The reproducibility of the experiments is secured by the speed stabilisation and the automatic gravimetric determination of the specific fuel consumption of the MP Computer. Example of application: Testing the efficiency of fuel additives or of other kinds of fuel pretreatment.

Request for a quote

WEINLICH GMBH & CO. KG

Germany

The MP Computer is a comfortable, comprehensive and easy-to-handle evaluation, display and control unit for different types of engine test beds. Its clear and ergonomic arrangement fascilitates the work with the test bed. Desired loads can be adjusted quickly and easily. Specialists are not required. Many optional additional functions increase enlarge the comfort of the MP Computer. Maintaining permanent accuracy of torque measurement is facilitated by a semi-automatic calibration routine. Existing engine/motor test beds can be modernized by an MP Computer. Examples of optional additional functions: - Automatic gravimetric determination of the specific fuel consumption. - Several possibilities of output and documentation of measured values. - Acquisition of non-electric and electric measuring values on combustion engines, electric machines, etc. - Special functions required by certain measuring tasks.

Request for a quote

SCHÜTZ GMBH MESSTECHNIK

Germany

Specially developed for the diverse tasks on the construction site, the Schütz Messtechnik company offers tailor-made measuring tools that reliably and comprehensively support the craftsman in all of his work “all around gas”. The complete solution for the load, leak tightness and usability test on gas pipes can be carried out safely and quickly, including documentation. GDPR-compliant as all personal data is protected against unauthorized access by a PIN. The measurement result can be printed out at the test point on site (optional), fully automatically and without interrupting the system. The professional solution for all measurements according to TRGI The prescribed load tests, tightness tests and usability tests, in the interior installation are possible with just one measuring device With integrated pump for pressure generation Very short measuring time through reference leak measurement PC software included

Request for a quote

ZWICKROELL GMBH & CO. KG

Germany

The low load Vickers hardness tester ZHV30 conducts Knoop and Vickers hardness tests in accordance to the ISO6507, ISO4545 & ASTM E 384.The test load range is between HV0.2 and HV30. With an an automatic 5 position turret for an indenter it consists of maximum of 4 lenses facilitating the change and selection through the menu buttons. The magnifications of 25x to 500x helps in covering various applications. Integrated microscope and front panel display facilitates quick and easy hardness testing. The dwell times may be easily configured in electronics and test cycle is automatic. The load change is automatic and the test load is selected through the operating panel. Illumination intensity for each magnification lens can be stored individually. PC controlled versions,based on a High Definition software, which are semi automated or fully automated are also available for automated and sophisticated applications.

Request for a quote

ZWICKROELL GMBH & CO. KG

Germany

The HB Servo-Hydraulic Testing Machine is specifically designed to provide an excellent quality performance and functionality. It is a high quality device which is built with a testing actuator mounter on top of the cross head. The superior quality apparatus is considered as a very versatile device to be used especially in conjunction with the T-slotted platform which allows flexure tests and component testing in addition to several fatigue tests. It is also available in a wide a range of versions for test loads from 50 to 2500 kN. The standard testing actuator stroke of 100, 250 or 400 mm. It can be supplied for 210 or 280 bar system pressure. The test frame features extremely high stiffness and natural resonance. Advantages and features • testing actuator mounted on upper crosshead • hydraulic clamping and adjustment for easy positioning of upper crosshead • comprehensive range of accessories, including hydraulic grips, compression platens, flexure test kit etc.

Request for a quote

ZWICKROELL GMBH & CO. KG

Germany

The Kappa creep testing machine is a flexible and highly-precised creep testing machine used for maximum cost-effectiveness. It is fully equipped with a test frame having four steel columns for high lateral and axial stiffness. It is powered by top-quality components that includes testXpert® II testing software and test control measurement and control devices. It has attained success due to its successful installations worldwide. It features an intelligent sensor technology which recognizes and calibrates all the sensors that are connected including their projected force limits and environments. It generally focuses on the most essential requirements of creep testing which include load, temperature, strain and data security.

Request for a quote

ZWICKROELL GMBH & CO. KG

Germany

Combining the bestThe ZHU250CL hardness tester employs the latest technology, with closed-loop control for test load application. The modern system for test load application (closed loop) stands out because of its precision. Accuracy exceeds the requirements of all relevant ISO and ASTM standards. Range of Hardness Applications: - Vickers according to ISO 6507, ASTM E384 - Knoop according to ISO 4545, ASTM E384 - Rockwell according to ISO 6508, ASTM E18 - Brinell according to IS0 6506, ASTM E10 Features: • Extremely wide test force range of 0.5 kg to 250 kg • Unique “4-plus-4” turret able to carry up to 4 lenses and up to 4 indenters simultaneously. The turret is also designed to allow testing in hard to reach positions by using a unique vertical rotation mechanism. • Variable dwell times 5-60 seconds • Ability to vary indenter approach velocity • Rockwell depth measured by the market leading Indentec transducer capable of a measuring resolution of 0.1 Rockwell point

Request for a quote

ZWICKROELL GMBH & CO. KG

Germany

The Zwick analog shore hardness tester is a testing device with a pointer. Due to its pointer, this tester can be used to measure value that is shown after the test in hard-to-access locations. Also, it can work in tests such as soft rubber, elastometers and natural rubber to Shore A. For tough materials, these includes harder elastomers, plastics and rigid thermoplastics to Shore D. This tool can work with either material that has different hardness rating coming from shore A up to Shore D. Plus, this test device have load weight and control unit which can be easily accessible.

Request for a quote

ZWICKROELL GMBH & CO. KG

Germany

Due to their design, Vibrophores have been used in the past solely as dynamic materials testing machines to determine durability with regard to fatigue life and fatigue limit, for example for fatigue testing to DIN 50100 (S-N curve) under tensile, compression, pulsating and alternating loads. The new generation of ZwickRoell Vibrophores can be used as both dynamic and full-fledged static materials testing machines that accommodate test loads up to 1000 kN. Typical applications are material fatigue tests and durability tests on standardized specimens and components (for example, piston rods, crankshafts, and screws) and production and quality control of components exposed to dynamic loads during their service lives, such as concrete and reinforcing steel, as well as quasi-static tensile and compression tests and fracture mechanics tests on CT and SEB specimens.

Request for a quoteResults for

Load testing - Import exportNumber of results

15 ProductsCompany type