- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- gas systems

Results for

Gas systems - Import export

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

ATMOSPHERIC PRESSURE, MAINTENANCE FREE AND PROTECTED AGAINST EXTERNAL EFFECTS The pressureless gas storage system of Lipp is used for the storage of gas produced on landfill sites, waste water treatment plants and also as external storage on biogas plants. The system is determined by its robust and technical advanced construction where the gas balloon is protected by a galvanized steel tank. This protects the balloon against UV light and also other external factors. The system is mostly utilized at landfill sites or WWTP to buffer the gas before its further processing. The experience gained during the past decades has improved the complete system and the single components and makes it a perfect choice for end users and general contractors.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

Beside the protection against external effects as UV or other external effects which could damage the foil, the unique construction enables a reliable and measureable leak test as well as an accurate filling level measurement at all times. Compared to low pressure systems and double membrane gas accumulators the Lipp system has very low operation and maintenance costs.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The RCV Plus™ Gas Mixing System is a combination of flow meters specifically designed to monitor and control the ratio of two gases. It consists of an RCV Plus™ and a FLO-TRONIC Plus™. The RCV Plus™ utilizes a micro-processor that continuously compares a preset ratio to the real-time ratio of the two gas flows, as measured by the FLO-TRONIC Plus™, and the ratio control valve itself. Using a stepper motor, the RCV Plus™ continuously adjusts the flow metering needle-valve to precisely maintain the preset gas ratio. The real-time ratio is continuously displayed on the LCD screen of the RCV Plus™. Included in the RCV Plus™ is an optional input for the addition of a trim gas, which is frequently used for process control. Trim gas addition is additive to the ratio. When trim gas is used, the continuously displayed real-time ratio then includes the trim gas addition.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

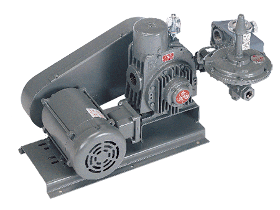

Gas Mixing Panels include the Waukee brand rotary vane compressors, air and gas Flo-Meters, and either a mechanical carburetor or RatioProver for precise ratio control. Panels are available with additive trim gas or air Flo-Meters. FEATURES: • Available with Lubed Vanes (includes a set of Phenolic Vanes and an Auto Lubricating System) or Non-Lubed Vanes (includes a set of Long Life Composite Vanes) • Available with outlet pressures ranging from 0.5-5.0psig. For higher pressures, consult UPC. • Two options available for ratio control: Standard Carburetor, RatioProver • Available with output capacities ranging from 200-12,000CFH • Available with Built-in Unloader for pressures between 0.5-2.5psig or with Bypass Relief Regulator for pressure lower than 0.5psig or higher than 2.5psig • Available with Standard turndown of 2:1 or 10:1 when used with a Compressor Pressure Controller • Includes Gas and Air Flo-Meters and Air Filter • Available with Trim Gas or Air Flo-Meters

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The Mixor™ is a precision compressor-carburetor device which accurately mixes gas and air in any selected ratio, and compresses it for use with endothermic cracking, or exothermic cracking generators, or as a source of pre-mixed gas and air for torch brazing, flame heat treating, or sort metal melting.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The EndoInjector™ is a precise gas mixing / control system for endothermic gas generators. It incorporates a patented fuel injection design that utilizes electronic flow measurement and precise ratio control to consistently provide the ideal gas mixture for high quality endo gas generation. The fuel injection design automatically delivers gas mixture on demand, providing only as much endothermic gas as furnaces require to reduce operating costs and eliminate gas waste. EndoInjector™ typically pays for itself in less than 1 year. The ExoInjector™ is designed specifically for exothermic gas generators. While similar in concept, the ExoInjector™ differs from the EndoInjector™ in that it comes in modified mechanical versions to accommodate pre-mix or nozzle-mix burners with a custom HMI software that allows for predefined ratio set points for burner ignition, rich exo, and lean exothermic gas. The system can be modified to provide hydrogen content control and water vapor monitoring.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The ExoFlex™ line of exothermic gas generators is designed to generate lean or rich exothermic gas. The generator includes automatic output turndown to 20% of the generator capacity with little loss of efficiency using the patented, maintenance-free ExoInjector™ gas mixing system. Thanks to a patented fuel injection technology that utilizes electronic flow measurement and precise ratio control, ExoFlex™ consistently provides the ideal mixture for high quality gas production. Another innovative design feature is the trim control input with programmable control range for precise generator control, which also eliminates the need for extra meters or valves. The ExoInjector™ easily replaces existing carburetor/pump designs for a significant reduction in process costs.

Request for a quote

SAR GRÖPLER GMBH

Germany

This gas filling system fills up the gas of shock absorbers and determins the gas strength and friction. It is also for manufacturing (filling) and testing.

Request for a quote

SAR GRÖPLER GMBH

Germany

Gasfüllanlage für externe Gastanks mit Lochstation und Trennkolbenöler Kolbenstangen-Prüfanlage: Mit dieser Anlage werden Kolbenstangen für Stoßdämpfer vorgeprüft und später zu einem fertigen Stoßdämpfer komplettiert. Die Anlage arbeitet vollständig automatisiert.

Request for a quote

HELANTEC GMBH

Germany

The HELOX 4 has been a proven test instrument for quality control of IG units for more than 30 years. The analyser is preferred by test institutes and the central labs of the insulated glass manufacturers. A paramagnetic measuring cell that selectively measures the residual oxygen, and which consequently is the primary measurement method, is used as the measuring technology for this analyser. This has the advantage that the user does not need to know which gas type is in the IG unit. On the display the gas concentration of the gas sample is shown. A rechargeable battery can be integrated as an option, which enables the devices to also be used directly on the construction site. A sample is injected with a gas syringe. This offers the advantage that only minimal gas quantities are required and you can check the function of the gas analyser yourself.

Request for a quote

HELANTEC GMBH

Germany

The SMART 150 is a small and handy gas filling system, equipped with the proven and high quality HELANTEC gas filling technology components. It enables a reliable filling process with easy operation. The capacity is configured for 150 units1) with one filling line. The SMART 150 gas filling system is suitable for occasional gas filling production of sample units smaller production facilities Gas concentration is measured continuously during the filling process by the integrated gas analyser. As soon as the set gas concentration is reached the filling process is ended automatically. Through the use of a pump, as well as the optimised filling speed, an extremely low gas consumption is realised. The SMART 150 can be used for all gases and gas mixtures that are standard in the insulated glass industry. The excellent priceperformance ratio will convince you.

Request for a quote

HELANTEC GMBH

Germany

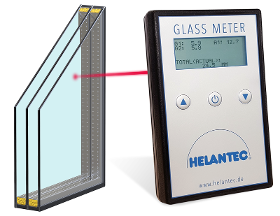

For insulated glass production, reliable quality control is indispensable. Consequently, reliable test methods are even more important. With HELANTEC devices, you get the technology to check the quality of your products. All devices are easy to use and very accurate. The GLASS METER is used for checking the thickness and distance of the glass panes, as well as the coatings. Features reliable measurement (glass thickness / air distance / LOWE coating) compact and handy design easy operability suitable for multicoated IG units suitable for tripleglazed units and all spacer materials nondestructive measurement We would be pleased to advise you in the selection of a suitable analyser for your requirements.

Request for a quote

HELANTEC GMBH

Germany

The GAS TESTER is our lowestprice entrylevel model for monitoring gas concentration. Naturally we have installed our proven analysis technology in this product as well. Features reliable concentration measurements compact and handy design easy operability argon and krypton use optional data storage Only a small quantity of gas is required. Sampling is executed with a special gas supply pump. The GAS TESTER is suitable for quality control of IG units with argon or krypton as the filling gas. If you desire to also analyse other gas types or gas mixtures, you should chose one of our other analysers.

Request for a quote

HELANTEC GMBH

Germany

With the ISOAltimeter PROFESSIONAL the IG unit is prepared in production in such a manner that it is flat at the higher altitude or lower altitude of the installation site. Additional aftertreatment is not required! The ISOAltimeter PROFESSIONAL is the further development of our proven predecessor model. Intuitive operation via touch screen, clear user guidance and versatile functions are only a few of the features that characterise our pressure balance system.

Request for a quote

HELANTEC GMBH

Germany

TURBOFILL has been developed exclusively for 1hole gas fill technology whcich is dilution filling. A special triplex probe combines argon fill, air suction and pressure sensing. It guarrantees as much turbulences as possible to replace the air with argon. At the same time it removes the air so that the internal pressure stays at a very low level to prevent the IG unit from bending. As soon as the adjusted concentration is measured the machine stops automatically. Equipped with 4 stations TURBOFILL realises up to 2000 IG units per day1). As for all other products this type as manufactured with high quality product that assure longlasting proven gas analysis. Thus TURBOFILL delivers constant gas fill quality for every IG unit.

Request for a quote

HELANTEC GMBH

Germany

The RAPIDE L200 is based on the HELANTEC fastfill technology and is the entrylevel model of the RAPIDE L series. The capacity with one filling line is approximately 300 units1). It is equipped with modern, progressive technology and enables efficient gas filling with reliable gas concentrations. This is measured continuously during the entire filling process via an integrated gas analyser. As soon as the set gas concentration is reached the filling process is ended automatically. Synchronisation of the filling and suction process also enables troublefree filling of large IG units. The handy device is well suited for changing implementation sites. The HELANTEC RAPIDE L200 also convinces with its extremely favourable priceperformance ratio. Are you looking for higher capacity and shorter cycle times? If so, consider our gas filling systems, RAPIDE L500 and RAPIDE L900.

Request for a quote

HELANTEC GMBH

Germany

The RAPIDE L500 is the top selling gas filling system with fastfill technology! This argon filling machine has proven itself for many years and represents the state of the technology. The investment volume of the system is unrivalled in terms of capacity. The RAPIDE L500 is more than "just" a manual gas fill system. With the integrated IPC the gas filling process is visualised and automatically documented. Only with this product you have a verification of quality for all filling processes, for each IG unit – automated, without additional effort. Allocation of the IG unit is executed via barcode. Thus traceability in terms of gas filling is also ensured. The capacity with 1 filling line is approximately 600 units with 2 lines the capacity is approximately 1200 units. Due to short cycle times, the RAPIDE L500 is excellently suited for integration in the insulated glass production. Operation is intuitive thanks to the minimal number of operating elements.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SMITO-TECHNIC GMBH

Germany

Scalable system, consisting of paint stripping, rinsing, conveyance of the workpieces, and (optional) vacuuming. Multitank systems can be manufactured on the basis of the TB400 or the TB1000. The basic unit is a system consisting of 1 paint stripping tank, 1 rinsing tank, drip station, semi-automatic conveyance system, and vacuum (optional). On this basis, we can design systems with various different paint stripping tanks (e.g., for different kinds of paint stripping agents), with one or several rinsing tanks, and (optionally) vacuuming for connection to the customer's waste gas disposal system.

Request for a quoteResults for

Gas systems - Import exportNumber of results

19 ProductsCompany type