- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- extraction systems

Results for

Extraction systems - Import export

EUGEN LÄGLER GMBH

Germany

The three-disc sanding machine for perfect fine sanding! Among other things, it is characterised by its extremely effective dust extraction performance. Another highlight is the near-edge and direction-free sanding. The TRIO is also versatile, extremely user-friendly and easy to maintain. Its mode of operation enables sanding results with highest quality. When it comes to achieving a premium quality of a wooden surface, the TRIO is the right choice! For example oiling and colouring a wooden floor create special challenges, which require a high surface quality. This task is mastered by the TRIO as well. Its ergonomic construction allows easy handling with minimal physical strain. Both, the abrasive and the dust bag, can be changed quickly and easily. Due to the integrated filter system, the dust extraction is very efficient, which enables almost dust-free sanding.

Request for a quote

SCHÜTZ GMBH MESSTECHNIK

Germany

With the telescopic aerial probe, any gas traces that may be present can be better detected. This is particularly recommended in pedestrian zones. Due to the high suction power of the extraction system, the gas concentration in the ground is already very diluted. However gas may still be later detected - but not with the telecopic aerial probe. Depending on the requirements, the telescopic aerial probe can be clicked into place quickly.

Request for a quote

KULLEN-KOTI GMBH

Germany

The removal of dust and electrostatic charges - we lead the way. Rotary ostrich-feather roller brushes remove dust from workpiece surfaces in accordance with a simple and reliable principle - due to their intrinsic electrostatic charge, the feathers lift dust from the workpiece surface. Gently and thoroughly. The dust ionised in this way remains on the feathers until removed by a suitable dust extraction system. Ostrich-feather roller brushes of Kullen-Koti consist of circular brush segments with standardised wooden cores, assembled to the requested face width and especially formed brush diameter for the car bodies. By using different outer diameters the roller brush can be adapted to the outline of the workpiece surface which is to be dedusted. Just contact us - without obligation - if you have any requirements.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

SYSTEM SOLUTIONS FOR SILAGE SILOS The Lipp dual seam system was and still is the basis for Lipp’s sustained success over the last few decades. Silage silos were already being built for agriculture with this system in the 1960s. The Lipp dual seam system is still employed today for the construction of silos and system solutions used for the storage of silage. In addition to pure container construction, system solutions for silage silos also include other components that go far beyond the scope of supply of a simple container manufacturer. APPLICATION EXAMPLES & REFERENCES Lipp system solutions for silage are used for storage and preservation of silage in an above ground, cylindrical container. Corresponding filling and extraction systems, roof and floor structures round off the scope of supply. A large number of the silage silos installed decades ago are still in operation today and provide proof of the high quality standard and extremely long service life.

Request for a quote

ZINSER GMBH

Germany

ZINSER GmbH offers an extensive range of accessories to optimize your flame cutting machines. Our accessories are designed to maximize the efficiency and performance of your cutting processes by allowing you to optimally adapt your machines to your specific requirements. Plasma systems Our plasma systems offer precise and fast cutting of metals and are ideal for various applications. With our plasma systems you can achieve clean and precise cuts with minimal material loss. Cutting tables with and without extraction Our cutting tables offer an effective solution for air purification and dust extraction during the cutting process. They are available in different designs to meet the requirements of different cutting applications. Extraction systems Our extraction systems are specially designed for plasma, oxyacetylene and laser cutting. They offer high filtration performance and help improve air quality and reduce maintenance costs.

Request for a quote

ZINSER GMBH

Germany

ZINSER GmbH offers first-class environmental technology solutions to complete your cutting systems. Our extraction and filter systems have been specially developed for applications such as plasma, oxyacetylene and laser cutting and set new standards in filtration performance and productivity. We offer you tailor-made solutions for systematic air purification to maximize the efficiency and safety of your cutting processes. Extraction and filter systems ZINSER extraction systems offer the highest performance and effectiveness. Our filter systems are available in various sizes and can be tailored to your specific requirements. They offer plug-and-go functionality, a closed design, quiet operation and high-performance filter cartridges that ensure improved cleaning efficiency and energy cost savings. ZINSER cutting tables Our cutting tables are the optimal solution for air purification during the cutting process.

Request for a quote

ELTEX-ELEKTROSTATIK-GMBH

Germany

Electrostatics disturb almost all production processes. Eltex systems prevent uncontrolled discharges and integrate electrostatics precisely into your processes. In our electrostatic discharge product portfolio, you will discover systems and products for many industrial sectors. The Eltex STATICTUBE RX11 tube ionization system was developed for use in pneumatic conveying systems. It removes static charges that are generated on the transported material during transport. The system is used in paper and plastic edge strip extraction systems.

Request for a quote

HELANTEC GMBH

Germany

The SMART 150 is a small and handy gas filling system, equipped with the proven and high quality HELANTEC gas filling technology components. It enables a reliable filling process with easy operation. The capacity is configured for 150 units1) with one filling line. The SMART 150 gas filling system is suitable for occasional gas filling production of sample units smaller production facilities Gas concentration is measured continuously during the filling process by the integrated gas analyser. As soon as the set gas concentration is reached the filling process is ended automatically. Through the use of a pump, as well as the optimised filling speed, an extremely low gas consumption is realised. The SMART 150 can be used for all gases and gas mixtures that are standard in the insulated glass industry. The excellent priceperformance ratio will convince you.

Request for a quote

HELANTEC GMBH

Germany

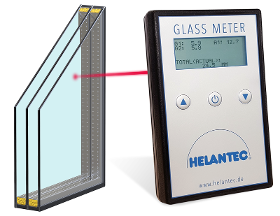

For insulated glass production, reliable quality control is indispensable. Consequently, reliable test methods are even more important. With HELANTEC devices, you get the technology to check the quality of your products. All devices are easy to use and very accurate. The GLASS METER is used for checking the thickness and distance of the glass panes, as well as the coatings. Features reliable measurement (glass thickness / air distance / LOWE coating) compact and handy design easy operability suitable for multicoated IG units suitable for tripleglazed units and all spacer materials nondestructive measurement We would be pleased to advise you in the selection of a suitable analyser for your requirements.

Request for a quote

HELANTEC GMBH

Germany

The GAS TESTER is our lowestprice entrylevel model for monitoring gas concentration. Naturally we have installed our proven analysis technology in this product as well. Features reliable concentration measurements compact and handy design easy operability argon and krypton use optional data storage Only a small quantity of gas is required. Sampling is executed with a special gas supply pump. The GAS TESTER is suitable for quality control of IG units with argon or krypton as the filling gas. If you desire to also analyse other gas types or gas mixtures, you should chose one of our other analysers.

Request for a quote

HELANTEC GMBH

Germany

With the ISOAltimeter PROFESSIONAL the IG unit is prepared in production in such a manner that it is flat at the higher altitude or lower altitude of the installation site. Additional aftertreatment is not required! The ISOAltimeter PROFESSIONAL is the further development of our proven predecessor model. Intuitive operation via touch screen, clear user guidance and versatile functions are only a few of the features that characterise our pressure balance system.

Request for a quote

HELANTEC GMBH

Germany

TURBOFILL has been developed exclusively for 1hole gas fill technology whcich is dilution filling. A special triplex probe combines argon fill, air suction and pressure sensing. It guarrantees as much turbulences as possible to replace the air with argon. At the same time it removes the air so that the internal pressure stays at a very low level to prevent the IG unit from bending. As soon as the adjusted concentration is measured the machine stops automatically. Equipped with 4 stations TURBOFILL realises up to 2000 IG units per day1). As for all other products this type as manufactured with high quality product that assure longlasting proven gas analysis. Thus TURBOFILL delivers constant gas fill quality for every IG unit.

Request for a quote

HELANTEC GMBH

Germany

The RAPIDE L200 is based on the HELANTEC fastfill technology and is the entrylevel model of the RAPIDE L series. The capacity with one filling line is approximately 300 units1). It is equipped with modern, progressive technology and enables efficient gas filling with reliable gas concentrations. This is measured continuously during the entire filling process via an integrated gas analyser. As soon as the set gas concentration is reached the filling process is ended automatically. Synchronisation of the filling and suction process also enables troublefree filling of large IG units. The handy device is well suited for changing implementation sites. The HELANTEC RAPIDE L200 also convinces with its extremely favourable priceperformance ratio. Are you looking for higher capacity and shorter cycle times? If so, consider our gas filling systems, RAPIDE L500 and RAPIDE L900.

Request for a quote

HELANTEC GMBH

Germany

The RAPIDE L500 is the top selling gas filling system with fastfill technology! This argon filling machine has proven itself for many years and represents the state of the technology. The investment volume of the system is unrivalled in terms of capacity. The RAPIDE L500 is more than "just" a manual gas fill system. With the integrated IPC the gas filling process is visualised and automatically documented. Only with this product you have a verification of quality for all filling processes, for each IG unit – automated, without additional effort. Allocation of the IG unit is executed via barcode. Thus traceability in terms of gas filling is also ensured. The capacity with 1 filling line is approximately 600 units with 2 lines the capacity is approximately 1200 units. Due to short cycle times, the RAPIDE L500 is excellently suited for integration in the insulated glass production. Operation is intuitive thanks to the minimal number of operating elements.

Request for a quote

HELANTEC GMBH

Germany

The RAPIDE L900 is the highest capacity gas filling system on the market and offers special advantages for the following applications fast filling and low gas losses particularly with krypton short filling times and extremely high capacity economic filling of extremely large formats fast filling of tripleglazed units in compliance with the cycle times of gas fill presses For development, this meant precisely regulating even larger gas quantities in the millisecond range. At the same time the universal implementation possibilities, the twohole technology and the proven closure system had to be retained. Nevertheless we were able to massively increase the efficiency. Here as well, and to an even more extreme degree, the same principle applies – namely that the maximum filling speed is not an expression of capacity. The crucial factor is efficient implementation.

Request for a quote

HELANTEC GMBH

Germany

The HELOX 4 has been a proven test instrument for quality control of IG units for more than 30 years. The analyser is preferred by test institutes and the central labs of the insulated glass manufacturers. A paramagnetic measuring cell that selectively measures the residual oxygen, and which consequently is the primary measurement method, is used as the measuring technology for this analyser. This has the advantage that the user does not need to know which gas type is in the IG unit. On the display the gas concentration of the gas sample is shown. A rechargeable battery can be integrated as an option, which enables the devices to also be used directly on the construction site. A sample is injected with a gas syringe. This offers the advantage that only minimal gas quantities are required and you can check the function of the gas analyser yourself.

Request for a quote

OPTIMA CONSUMER GMBH

Germany

Properties: Filling with gross weighing system Capacity of up to 250 containers/min. Fills metal cans Low space requirement, integration solution for monoblock with a sealing machine Filling process with cup dosing machine Maximum accuracy thanks to precisely manufactured fill heads Rotating carrier segments Vibration over the entire transport area beneath the funnels Mean value controller Max./Min. jam detection Recognition of container top/bottom Gas Flushing “No jar no fill” system Options: Installation of an Optima extraction system for product extraction <1%

Do you sell or make similar products?

Sign up to europages and have your products listed

Results for

Extraction systems - Import exportNumber of results

18 ProductsCompany type