- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- drawings

Results for

Drawings - Import export

SIMPAC EUROPE GMBH

Germany

Compact presses for a wide range of medium sized parts. Due to its drive-related slide kinematics, the MCL series is particularly suitable for drawn parts. Overview: ● Pressing capacity: 3,000 - 8,000 kN ● Component size: medium ● Slide kinematics: link ● Applications: stamping, drawing, forming Features and benefits: ● The compact design requires little floor space and no foundation at presses below 4,000 kN. ● The very solid, low-stress annealed press bodies are FEM-calculated and optimized by so-called “hot-spot analysis” in areas which are subject to higher loads. ● Motor, clutch/brake unit, lubrication system and control are of German origin and guarantee a long service life and maximum dynamics. ● The slide guiding system ensures a high level of tilting rigidity and reduces the cutting impact during the cut through when it comes to the processing of higher-strength materials.

Request for a quote

PRESSTECK S.P.A.

Germany

We are experts in deep-drawn parts made of stainless steel, deep-drawn parts made of aluminium and other non-ferrous metals (including brass, copper and nickel silver). To produce your perfect component, we also have the option of using carbon steel, special nickel alloys (e.g. Inconel®), but also soft magnetic materials. Each material has specific properties that need to be taken into account in the forming process. We manufacture deep-drawn parts with a diameter of 2 to 80 mm and a length of up to 120 mm. We process material thicknesses from 0.05 to 2.50 mm. Pharmaceuticals and medical technology, industry, consumer and automotive: we are primarily active in these fast-growing sectors. We are not only specialists in deep drawing, but also know the industrial requirements and process chains. Depending on your requirements, we complement deep-drawing with numerous secondary finishing processes up to fully automated assembly systems.

Request for a quote

PRESSTECK S.P.A.

Germany

You don't need deep-drawn individual parts, but complex assemblies already assembled? We are your experts for that! First we analyse your requirements for new potentials. Combined with innovative thinking and agile processes, we then design smart solutions with you to manufacture your desired assemblies. Depending on your requirements, we develop decoupled, partially or fully interlinked assembly processes using high-performance systems and state-of-the-art equipment. We reliably ensure your quality requirements with integrated and individual testing measures.

Request for a quote

PRESSTECK S.P.A.

Germany

Pressteck is one of the world's leading specialists for deep-drawn individual parts on transfer presses and their processing into assemblies. In this non-cutting tension-pressure process, we produce hollow parts from a metal strip in several stages, which can be aluminium, stainless steel, copper or brass, among others. Compared to other processes, deep drawing has decisive advantages: Material consumption and production costs are lower, and at the same time the strength of the components is higher. We are highly innovative and optimise deep drawing technology beyond what is currently possible. We manufacture your individual component from coiled sheet metal and master demanding geometries and high degrees of forming.

Request for a quote

PRESSTECK S.P.A.

Germany

Thermostatic valves - i.e. the temperature controls on the heating system - are found in just about every home. In the head of a thermostatic valve there is a metal bellows, a corrugated tube that expands according to the room air temperature. For these metal bellows, the manufacturer needed deep-drawn, very long and thin-walled sleeves. The challenge: the sleeves must be matched to the customer's downstream process under very tight tolerance specifications. Why? Because the sleeves cannot be further processed if the geometries vary. Absolute precision is therefore required. We can offer absolute precision. The customer commissioned us with the production of the sleeves. On the one hand, because we fulfil the special deep-drawing requirements. On the other hand, because we can offer an associated, targeted heat treatment for material stress relief in-house.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PRESSTECK S.P.A.

Germany

For our customers in the automotive and housing industry, we produce deep-drawn stainless steel pots with an integrated axle as a monobloc component. These are used in water pumps for electric vehicles. Our customer from the automotive industry needs pots with an integrated axle that holds a rotor. Up to now, the pot and axle have been joined in a centred manner by means of welding. The customer's wish was to produce a one-piece component to avoid welding. Deep drawing is the ideal technology for this. The size of the component required larger presses than were previously available. Therefore, we first developed tools as prototypes for larger presses on behalf of the customer. After practical tests at the customer's premises as well as at the end customer's, our client decided on a tool that was ideally suited for the production of the component in series.

Request for a quote

PRESSTECK S.P.A.

Germany

Support sleeves for reinforcing plastic components. Made of stainless steel with customised design. The bushings can be produced not only round but also oval as a deep-drawn part.

Request for a quote

PRESSTECK S.P.A.

Germany

We are experts in deep-drawn parts made of stainless steel, deep-drawn parts made of aluminium and other non-ferrous metals (including brass, copper and nickel silver). To produce your perfect component, we also have the option of using carbon steel, special nickel alloys (e.g. Inconel®), but also soft magnetic materials. Each material has specific properties that need to be taken into account in the forming process. We manufacture deep-drawn parts with a diameter of 2 to 80 mm and a length of up to 120 mm. We process material thicknesses from 0.05 to 2.50 mm.Pharmaceutical and medical technology, industry, consumer and automotive: we are primarily active in these fast-growing sectors. We are not only specialists in deep drawing, but also know the industrial requirements and process chains. Depending on your requirements, we complement deep-drawing with numerous secondary finishing processes up to fully automated assembly systems.

Request for a quote

PRESSTECK S.P.A.

Germany

Pressteck has all standard sizes of MDI containers in its portfolio: 10ml, 14ml, 17ml and 19ml. If you need other sizes due to individual requirements, we are happy to offer these as well. Pressteck has all standard sizes of MDI containers in its portfolio: 10ml, 14ml, 17ml and 19ml. If you need other sizes due to individual requirements, we will be happy to offer you these as well. Depending on the medication and the propellant (CFC or HFA), different materials are used. We produce our containers from aluminium and stainless steel. While stainless steel containers are usually used uncoated, aluminium containers can also be offered in a coated version. Our containers are used as primary packaging for the administration of aerosol medication by inhaler. Patients worldwide use MDI (metered-dose inhalers) to treat respiratory diseases such as asthma and COPD.

Request for a quote

TAVRIDA ELECTRIC

Germany

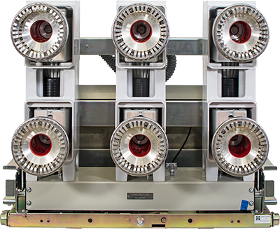

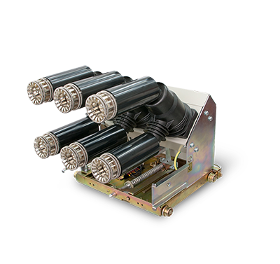

Tavrida Electric develops and manufactures drawout vacuum circuit breakers with lightest weight (only 72 kg) and the fastest opening time (only 12 ms*) VCBs on the market. The circuit breaker is maintenance free and guarantees long mechanical and electrical life. Draw out units are assembled to be easily integrated into existing switchgear designs. Complete with the rackin cassette, guidearms, tulip contacts and safety interlocks Tavrida Electric withdrawable vacuum circuit breakers are perfectly suited for drawout panels manufacturing. *Special configuration available with opening times of 12 ms and closing times of 24 ms.

Request for a quote

VIDEODESK STUDIO LIGHTBOARD

Germany

Illuminated transparent board for drawing with fluorescent markers. It is widely used in educational institutions, as well as when recording video. The text is visible clearly and vividly. Thanks to the RGB backlight, you can change the color of the written text. Glass size: 60x90cm; 80x120cm; 100x150cm; 100x174cm, 110x195cm Glass type: diffusing,chemically brightened, with edge polished. Glass thickness: 6 mm. Frame: metal, welded, powder painted. Glass frame base, metal Equipped with RGB edge lighting. Front lighting is located at an angle of 45 degrees. Color temperature: 5500 Kelvin. The power supply is located inside the structure. Includes 4 LED backlight strips. The RGB backlight is connected to the controller and has the ability to change color. Both lights are equipped with a toggle switch that turns both light strips on and off.

Request for a quote

SIMPAC EUROPE GMBH

Germany

The Scotch-Yoke drive of the DTL series has a modified link drive characteristic and reduces the slide speed during the forming phase. Thus the presses are not only suitable for cutting, punching and forming tasks, but also for drawing operations. The extra time that the material receives for plastic flow significantly increases the quality of the produced parts. The reduced impact speed of the slide extends the life of the press and the die. Overview: ● Press capacity: 6,000 - 30,000 kN ● Part size: large ● Slide kinematics: link ● Application: as a single press system either as progdie or transfer mode, as well as a press line Description and benefits: ● The outside located pressure points and a long 8-fold slide guiding system well compensate off-center loads, spare press and die and ensure a constant part quality. ● The automatic centralized lubrication system increases pro-ductivity and availability.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Extremely high clamping force Often complete machining fails for lack of an effective I.D. clamping device. In many cases the jaw chuck is a makeshift solution. However, even conventional mandrels with slotted clamping sleeves quickly reach their limits in terms of accuracy, rigidity, and opening stroke. HAINBUCH segmented mandrels use state-of-the-art clamping technology that is convincing, even in the most critical applications. Segmented clamping bushing with extremely hard, wear resistant and rigid segments The central element is the vulcanized segmented clamping bushing. Because conventional clamping bushings are made of spring steel and are only annealed to spring hardness, they are »soft« and they must »bend« to clamp the workpiece. HAINBUCH segmented bushings, on the other hand, are made of case-hardened chromium-nickel-steel and have segments that are extremely hard, wear resistant and rigid.

Request for a quoteResults for

Drawings - Import exportNumber of results

16 ProductsCompany type

Category

- Drawing - steel and metals (9)

- Forming - steels and metals (8)

- Electric transformers, converters and rectifiers (3)

- Metal industrial presses (2)

- Machine tools, metal machining - parts and accessories (1)

- Audio-visual equipment, professional (1)

- Audio-visual teaching aids (1)

- Distance Learning and e-Learning (1)

- Medicines (1)

- Writing boards (1)