- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- containers- flexible

Results for

Containers- flexible - Import export

BÜRKLE GMBH

Germany

PumpMaster, canister and barrel pump for petrochemical liquids. The manual pressure pump is ideally suited for drawing off, decanting and emptying canisters and barrels. The hand pump is used to create excess pressure that forces the liquid out of the container. The stopcock also allows extraction of small quantities of liquid. The PumpMaster container pump is mounted on the container using a flexible stopper with a variable and adjustable diameter. No special thread adapters are required. PumpMaster fits all commercial container openings with a diameter from 46.5 mm to 60 mm. The immersion tube has a length of 95 cm and it can be shortened depending on the size of the container.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

SYSTEM SOLUTIONS FOR THE STORAGE OF SLURRY Following the further development of the Lipp dual seam system and the container material it was possible not only to build silos for bulk materials, but also silos for the storage of liquids, such as liquid manure. Since slurry is also rather more aggressive and can attack concrete or similar vessels, especially over the years, Lipp always offers its system solutions for the storage of slurry in principle in V2A stainless steel (1.4301), when it is clear that the tank will remain open. Possible changes are also taken into account with the customer during the planning process and in case of a future modification of the slurry tank consideration is given to an alternative material (V4A) or the possibility of a subsequent roof construction. Thus, the container retains its flexibility and can later be converted into a fermenter, secondary fermenter or other container.

Request for a quote

BIZERBA SE & CO. KG

Germany

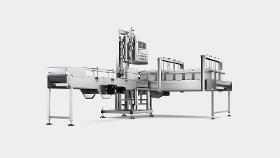

The fully automatic filling system optimizes your product quality by to-the-gram weighing, safe packaging even of flammable, foaming or corrosive liquids and through gentle dosing. By means of a multifunctional offset slide you benefit from maximum flexibility for container types and sizes as well as from efficient handling without retrofitting time. The fully automatic machine FSL-EVO S facilitates quick and reliable filling of high quality and sensitive products in different containers. Products can be fully automatically closed and labeled with variable data, if desired. By means of a set up buffer section the filling system largely works autonomously.

Request for a quote

OPTIMA CONSUMER GMBH

Germany

The OPTIMA MPS is a modular machine specially designed for the packaging of food and chemicals. Liquids dossing or filling systems for powders can be integrated. The two-lane solution for stable, self supporting containers can flexibly fill liquid into formats ranging from cylindrical bottles to canisters. The mass flow filling system is installed on a mobile filling trolley, which allows quick product changeovers while reliably preventing cross-contamination. Additional functions such as handling processes, sealing, flushing, inspection and more can be integrated. The highly accessible system with explosion protection can also be equipped with a CIP unit.

OPTIMA CONSUMER GMBH

Germany

Containers: - Container classification via the infeed screw - Container transport using pucks for flexible production and fast conversion - Cycled container transport - Continuous container transport - Very gentle processing of the containers and packaging - Processing different container shapes Shapes: - User-friendly, fast and primarily tool-free format change - Fully or semi-automated format change is optional

Do you sell or make similar products?

Sign up to europages and have your products listed

OPTIMA CONSUMER GMBH

Germany

Containers: - Container or cap feed as bulk goods via fully automatic sorting and optional storage bin - Raising the container when filling to prevent dust accumulation - Container transport using pucks for flexible production and fast conversion - Centering the container for the optimal positioning of the containers below the work stations - Cycled container transport - Optimized container transport for preventing splashing in little headroom - Very gentle processing of the containers and packaging - Processing different container shapes Manufacture/Closing: - Simple integration into existing packaging technologies - Process-reliable sealing using thermal sealing, induction or ultrasound is possible - Processing all standard types of caps - Processing packaging material from the stack

OPTIMA CONSUMER GMBH

Germany

Containers - Container or cap feed as bulk goods via fully automatic sorting and optional storage bin - Container classification using a rotary feeder - Container transport using pucks for flexible production and fast conversion - Container transport without pucks possible - Cycled container transport - Very gentle processing of the containers - Processing different container shapes Shapes -User-friendly, fast and primarily tool-free format change Design - Simple assembly (plug and play) - low installation costs - Good visibility and accessibility - Compact design with low space requirement - Compact design with integrated control cabinet - Secure and sturdy mechanical system Drive - Drive via wear-free servomotors Manufacture/Closing - Positioning the caps manually for semi-automatic processes - Closing systems coordinated to the product

OPTIMA CONSUMER GMBH

Germany

Filling - Filling systems coordinated to the product - Freely programmable filling nozzle movement and filling speed for below/over or bottom-up filling Containers - Container classification using a portioning device - Container transport using pucks for flexible production and fast conversion - Container transport without pucks possible - Centering the container for the optimal positioning of the containers below the work stations - Cycled container transport - Very gentle processing of the containers - Processing different container shapes Design - Simple assembly (plug and play) - low installation costs - Good visibility and accessibility - Compact design with low space requirement - Compact design with integrated control cabinet - Running direction of the machine from left to right - Min./max. Sensors for jam detection upstream and downstream of the machine - Secure and sturdy mechanical system

OPTIMA CONSUMER GMBH

Germany

Containers: - Container classification using a rotary feeder - Container classification via the infeed screw - Container transport using pucks for flexible production and fast conversion - Cycled container transport Shapes: - User-friendly, fast and primarily tool-free format change Design: - Simple assembly (plug and play) - low installation costs - Good visibility and accessibility - Compact design with low space requirement - Compact design with integrated control cabinet - Glue gap or tuck-in gap closure is possible - Modular machine design for maximum flexibility for future adaptations of products, packaging or functions - Few moving parts resulting in minimized sealing and maintenance costs

Results for

Containers- flexible - Import exportNumber of results

10 ProductsCompany type