- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- clamping elements

Results for

Clamping elements - Import export

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

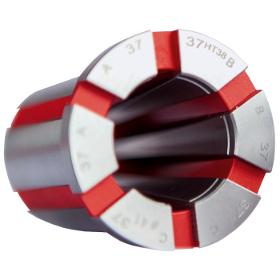

With our hexagonal clamping heads you get up to 25 % more clamping force and higher output with the same clamping cylinder actuating force that is used to actuate our SPANNTOP chucks. The pyramid arrangement of glide surfaces makes it possible. In addition the hexagonal geometry ensures that TOPlus is more resistant to contamination than former clamping head / chuck systems. Therefore, TOPlus is even better suited for raw material, cast and forged parts, as well as fine-particle non-ferrous metals such as brass. With a concentric precision of ≤ 0.005 mm!

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

In terms of precision, stability, and flexibility the vulcanized segmented clamping bushings are unbeatable. They consist of segments made of chrome/nickel, case hardened steel that is very hard, extremely wear resistant, and rigid [60 HRC]. Plus, they do not have to »bend« to clamp the workpiece. In addition, all functional surfaces are completely ground in one clamping set-up. The result: maximum run-out accuracy, maximum holding power, and long life span.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

This development represents more than 30 years of SPANNTOP experience. It exploits all the advantages of the latest machine tools. This clamping head is not only extremely powerful, it is also convincing through simple handling. With the changing fixture you set up in no time. The combination of steel and rubber, specially developed by HAINBUCH, in conjunction with a vulcanization that has been perfected over decades, is designed for maximum speed and holding force – with optimal concentricity, and incredible rigidity and service life.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

With our hexagonal clamping heads you get up to 25 % more clamping force and higher output with the same clamping cylinder actuating force that is used to actuate our SPANNTOP chucks. The pyramid arrangement of glide surfaces makes it possible. In addition the hexagonal geometry ensures that TOPlus is more resistant to contamination than former clamping head / chuck systems. Therefore, TOPlus is even better suited for raw material, cast and forged parts, as well as fine-particle non-ferrous metals such as brass. With a concentric precision of ≤ 0.005 mm!

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

The segmented clamping bushing SE with the hexagon socket sits on the clamping pyramid, absolutely form-fitted in every clamping position and thereby enables maximum machining performance with minimal vibration and thus less tool wear. The full-surface contact of the segmented clamping bushing on the mandrel ensures a significantly better insensitivity to contamination than previous segmented clamping bushing/mandrel systems. Therefore, these segmented clamping bushings are even better suited for raw material, cast and forged parts, as well as fine-particle non-ferrous metals such as brass. And they offer this suitability at run-out of ≤ 0.01 mm and in the premium version at ≤ 0.007 mm.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WEINLICH GMBH & CO. KG

Germany

- self-supporting bed, - no transfer of torque to the ground - rapid fixation of modules and additional equipment in any axial position without drilling Picture: The modules executing torque on each other consist of electric motors with a high torque transmission. They are secured by strong clamping elements on the test bed. Their axial position is adjustable. The removable protection grid protects only against accidental contact to rotating parts under laboratory conditions. Solid axially movable protection covers are avaiable if parts might detach and fly away.

Request for a quote

BOLZ PROCESS TECHNOLOGY GMBH

Germany

Pharma Design - Series H 630 - 1600 P The HEINKEL horizontal peeler centrifuges in pharma design are characterized by easy cleaning and inspection avoiding product contamination. Special properties for the customer’s benefit: Swinging open housing for easy inspection Clean room installation possible Hydraulically operated housing locking mechanism by single clamping elements, therefore minimal area for product deposit Fully automatic, validated CIP-process possible Design virtually free of dead spaces, minimized number of screwed connections in the process housing Filtrate outlet at the rear part of the process housing, low dismantling expenses to prepare for the opening of the housing High flexibility at frequent product changes Quick change of the filter element Bearing designed as exchangeable unit

Request for a quote

ANDREAS MAIER GMBH & CO. KG (AMF)

Germany

Standard clamping technology from AMF: versatile, durable, reliable. The highest level of quality applies to this exceptional versatility as well. Every product meets the demand for innovation and the specific requirements within the scope of practical application.

Request for a quote

ANDREAS MAIER GMBH & CO. KG (AMF)

Germany

Toggle clamps from AMF: versatile, strong, durable. Tried-and-tested technology with ever new variants. The benefits of our toggle clamps are highly valued in many fields of application: in the metal industry for drilling, welding, bending, grinding, checking and mounting as well as for the machining of wood and plastic in gluing, drilling, cutting and milling fixtures.

Request for a quote

ANDREAS MAIER GMBH & CO. KG (AMF)

Germany

Zero-point clamping technology from AMF: economical, strong, precise. The Zero-point system from AMF has virtually revolutionised the zero-point clamping technology market with technological superiority. The highly precise clamping modules with high draw-in, locking and holding forces ensure perfect clamping in the widest range of applications.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Lower mass The »mini« series really shines with a mass reduced by as much as 30 %, and a chuck diameter that is reduced by 1/3. This means reduced energy consumption and better tool accessibility. Naturally, add on clamping elements can also be used with the TOPlus mini chuck. To maintain the minimal interference contour, the TOPlus mini chuck has its own adaptation devices with a smaller bolt hole circle. Reduced interference contour Thanks to the reduced interference contour, it is easier to choose the tool that you need. Now it can also be shorter and more stable – on the main and sub spindles. Particularly in the case of limited installation space and in series operation, the TOPlus mini chuck is ideal: Lower energy consumption, dynamic spindle acceleration, and shorter cycle times reduce the costs per workpiece. Minimalism that pays off!

Request for a quote

ASSFALG GMBH

Germany

Whether while milling (rough and finish machining), drilling, sawing, welding or assembling, the EPM modules or module systems offer a large selection of clamping options, for example, to clamp during edge milling or deburring (without mechanical clamping equipment) or for the simple and quick fastening of workpieces during assembly. Workpieces can be easily and quickly fastened with the Doublemag magnet clamping elements. Through the use of pole extensions, any unevenness on the workpiece can be compensated for and a deformation of the workpiece can be prevented. Using pole extensions, plane-parallelism of up to 0.01 mm is possible on the workpiece. The processing runs without vibration and an even distribution of holding force is guaranteed throughout the entire ferrous clamping surface. Several Doublemags can be combined to process large parts.

Request for a quote

ASSFALG GMBH

Germany

Whether while milling (rough and finish machining), drilling, sawing, welding or assembling, the EPM modules or module systems offer a large selection of clamping options, for example, to clamp during edge milling or deburring (without mechanical clamping equipment) or for the simple and quick fastening of workpieces during assembly. Workpieces can be easily and quickly fastened with the Triplemag magnet clamping elements. The Triplemag series has additional positioning magnets, ensuring a constant position on the machine table and which are separately switched. Through the use of pole extensions, any unevenness on the workpiece can be compensated for and a deformation of the workpiece can be prevented. Using pole extensions, plane-parallelism of up to 0.01 mm is possible on the workpiece. The processing runs without vibration and an even distribution of holding force is guaranteed throughout the entire ferrous clamping surface.

Request for a quoteResults for

Clamping elements - Import exportNumber of results

14 ProductsCompany type