- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- centrifugation

Results for

Centrifugation - Import export

LUTZ PUMPEN GMBH

Germany

The B80 KGK G3 series is a powerful and robust submersible centrifugal pump with plain bearings, drive lantern mounted on anti-friction bearings and IEC standard motor. The B80 KGK G3 series is designed in single or two-stage versions with one or two impellers for high flow rates. Multistage pumps are used to increase the delivery pressure while maintaining compact hydraulic dimensions and are used in particular in processes with high delivery pressures at low flow rates. They are perfectly designed for industrial use in closed unpressurized tanks, basins or pits. * suitable for flow rates up to 270 m³/h * equipped with a suction strainer as standard * a suction pipe extension up to 2000 mm is possible * available in immersion depths from 500 - 4000 mm Features & Advantages * vibration and oscillation free operation * Efficient and space-saving design due to 1- and 2-stage pump hydraulics * Long operational reliability

Request for a quote

LUTZ PUMPEN GMBH

Germany

The B80 KGK G1 series (with closed impeller) is a powerful and robust centrifugal submersible pump with plain bearings, drive lantern on roller bearings and IEC standard motor. The pumped liquid is conveyed from the tank via the radial pump outlet and the vertical riser pipe. Power is transmitted from the motor to the pump by means of a torsionally flexible, positive-locking coupling and is designed for continuous operation. * Suitable for flow rates up to 30 m³/h * equipped with a suction strainer as standard * suction pipe extension up to 2000 mm is possible * available in immersion depths from 500 - 4000 mm Features & advantages * No screws in contact with the medium * Vibration and oscillation-free operation * Long service life and operational reliability * Lifetime grease-lubricated roller bearings * Independent bearings for motor and pump * External flushing to protect the plain bearings with media containing solids

Request for a quote

LUTZ PUMPEN GMBH

Germany

The B80 KGK G2 series (with open impeller) is a powerful and robust centrifugal submersible pump with plain bearings, drive lantern with roller bearings and IEC standard motor. The pumped liquid is conveyed from the tank via the radial pump outlet and the vertical riser pipe. Power is transmitted from the motor to the pump by means of a torsionally flexible, positive-locking coupling and is designed for continuous operation. *Suitable for flow rates up to 80 m³/h * equipped with a suction strainer as standard * suction pipe extension up to 2000 mm is possible * available in immersion depths from 500 - 4000 mm Features & advantages * No screws in contact with the medium * Vibration and oscillation-free operation * Long service life and operational reliability * Lifetime grease-lubricated roller bearings * Independent bearings for motor and pump * External flushing to protect the plain bearings with media containing solids

Request for a quote

FLUX-GERÄTE GMBH

Germany

FLUX centrifugal immersion pumps are used when larger flow rates, continuous running or special immersion lengths are required. They are especially suitable for pumping and circulating aggressive and abrasive media. There is a choice of different materials available depending on the chemical and thermal requirements. In addition sealless and horizontal versions are available. FLUX centrifugal immersion pumps are individually configured and manufactured according to the technical requirements in each case.

Request for a quote

HO-MA GMBH

Germany

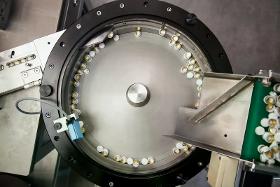

Centrifugal sorting is used for high capacities up to 800 pieces per minute. The quiet and gentle sorting is particularly suitable for plastic objects. Depending on object type and size we recommend different versions ZF-350, ZF-500, ZF-800. Due to the user-friendly and space-saving design, it can be combined with other machines and systems.

Request for a quote

LUTZ PUMPEN GMBH

Germany

The TMR series is a reliable magnetic drive pump that easily handles critical operating conditions due to its patented magnetic axial thrust compensation. * Drive via magnetic coupling with patented magnetic axial thrust compensation * Typical applications: Acids, alkalis, acid and alkali mixtures, solvents, alkaline degreasing baths, electroplating baths, photographic chemicals Features & Advantages * Variable connection options * Compact dimensions, performance in line with requirements * Also for liquids with high density * Due to "magnetic axial thrust balancing" the bearing system "R" is suitable for dry running * Motor and pump are mechanically separated * Connections with thread or flange

Request for a quote

LUTZ PUMPEN GMBH

Germany

High performance, compact dimensions, low weight - everything fits with the Lutz B6. The pump shaft is protected by a shaft guide tube against possible "attack" of the pumped medium. Perfectly suited for pumping and draining of neutral and aggressive liquids with low solids content. * on request also available in special immersion depths of 1000 - 3000 mm * Design according to the single pipe principle * Application examples: For conveying and circulating chemicals and solutions in surface treatment, chemical industry and water treatment, etc. Features & Advantages * Wide range of applications * No risk of leakage at the bottom outlet due to safe product removal * Low wear * Stationary installation possible via flange * Also for small container openings

Request for a quote

LUTZ PUMPEN GMBH

Germany

The AM series was specially developed for for the medium performance segment in plant and apparatus engineering. High-quality housing and bearing materials enable adaptation to almost any conveying task as required. * Drive is via a magnetic coupling * Examples of applications: Acids, alkalis, acid and alkali mixtures, solvents, alkaline degreasing baths, electroplating baths, photographic chemicals Features & Advantages * Variable connection options * Compact dimensions, performance in line with requirements * Also for liquids with high density * Version "R" conditionally suitable for dry running * Motor and pump are mechanically separated * Connections with BSP thread or hose nozzle

Request for a quote

LUTZ PUMPEN GMBH

Germany

The TMB series was specially developed for installation in small systems and apparatus. The single-stage Centrifugal pump offers robust technology in the smallest space. * Drive is via a magnetic coupling * Typical applications: Acids, alkalis, acid and alkali mixtures, solvents, alkaline degreasing baths, electroplating baths, photographic chemicals Features & Advantages * Variable connection options * Compact dimensions, performance in line with requirements * Connections with BSP thread or hose nozzle * Ideal for mobile use * Motor and pump are mechanically separated

Request for a quote

LUTZ PUMPEN GMBH

Germany

When circulating chemicals and pickling baths, reliability, safety and last but not least functionality are important. The submersible centrifugal pump was specially developed as a vertical, wet-installed pump for the rapid emptying of these liquids from tanks and basins. * available in special immersion depths on request * equipped with self-lubricating, liquid-wetted plain bearings. Features & Advantages * High flow rate * High efficiency * Smooth running * Low space requirement * Easy commissioning * Easy to maintain * The maximum flow rate is a value determined by means of a test bench and measured with water at a liquid temperature of approx. 20 °C . The measurement is taken at the pressure joint of the pump, without hose, nozzle or flow meter.

Request for a quote

LUTZ PUMPEN GMBH

Germany

The B80 KME series was developed as a wet-installed centrifugal immersion pump for stationary use in tanks and basins. The direct-coupled pump with plain bearings is suitable for pumping and circulating neutral and chemically aggressive liquids in the chemical industry and process engineering, in electroplating and surface technology, in washing systems and water treatment plants, for sump drainage in industrial and municipal waste disposal plants or as a circulation pump in gas scrubbers and heat exchangers. * with various plain bearing designs * available in immersion depths from 600 - 1500 mm Features & Advantages * Compact dimensions * Abrasion resistant material combinations possible * Extremely low-vibration and low-wear operation * All wetted parts made of corrosion resistant plastic * Self-centering alignment in the bearing shell

Request for a quote

LUTZ PUMPEN GMBH

Germany

The B80 HME series is a design with bearingless cantilever construction that is directly coupled to the IEC Motor. Specially designed for plant engineering and confined installation conditions. It can be operated in dry installation next to the tank, thus facilitating access for maintenance and repair work. The pump is suitable for pumping /circulating neutral, corrosive and mechanically contaminated liquids. However, it can also be used in stationary installation in the chemical industry and process engineering, in surface and electroplating technology and in gas scrubbers. * temporarily also possible in dry running * directly coupled in bearingless cantilever design * available in immersion depths from 275 - 450 mm Features & Advantages * Service friendly dry running installation * Extremely low vibration and wear operation * Self-centering alignment in the bearing shell * All wetted parts made of corrosion resistant plastic

Request for a quote

BOLZ PROCESS TECHNOLOGY GMBH

Germany

Series V 300 - 700 TM The HEINKEL Multipurpose centrifuges V 300 – V 700 TM are known as robust, economical and reliable centrifuge. Fields of application are the de-oiling of parts or chips and drying of bulk parts, further the oiling or impregnation of bulk goods. Special properties for the customer´s benefit: Rugged, long life design based on the modular principle Very simple to operate – optionally to be improved through a basket lifting device Speed control Flexible deployment directly at the place where the chips are produced Maintenance friendly

Request for a quote

BOLZ PROCESS TECHNOLOGY GMBH

Germany

Series V 600 - 1100 IS The HEINKEL Vertical De-oiling Centrifuge V 600 – 1100 IS is designed and built for the separation of cutting fluids and coolants from steel, cast and metal chips. Special properties for the customer’s benefit: Recovery of liquids and oil from chips produced by processing centres and from plastic pellets Simple and rugged design

Request for a quote

BOLZ PROCESS TECHNOLOGY GMBH

Germany

Series V 425 TT & V 450 TT Ex The HEINKEL Coating Centrifuge V 425 TT, is an economical solution for the coating of small parts with oil, paint, adhesive binders and the like. It spins away excess coating material optimally and it is also easy to install. For hazardous Ex zones HEINKEL has developed and built the Coating Centrifuge V 450 TT Ex. Special properties for the customer’s benefit: Economic coating of small parts with oil, lacquer, adhesive coatings etc. Optimised spinning off of excess coating material Simple installation

Request for a quote

BOLZ PROCESS TECHNOLOGY GMBH

Germany

V 630 BK - TIOCENT The HEINKEL Classifying centrifuges are used for continuous wet classification of fine, ultrafine and nanoparticles in slurries. They provide a precise cut for optimal production of specific slurries. The highly reliable operation maximizes the cost-benefit ratio. Special properties for the benefit of the customer: Precise separation cut Easy adjustment of separation cut High throughput Recycling of the coarse particles Simple installation Low maintenance complexity, maintenance friendly design Electrically operated turbulence blade Discharge of classified suspension through a pneumatically operated siphon

Request for a quote

BOLZ PROCESS TECHNOLOGY GMBH

Germany

Chemical Design - Series V 630 - 1600 TC The classical HEINKEL top discharge centrifuges are a cost-effective alternative in chemical manufacturing. The centrifuge can be easily adapted to the product characteristics and is therefore suitable for companies that manufacture a variety of products in small to large batches. Special properties for the benefit of the customer: Flexible adaptation for difficult to filter products Lossless filter cake discharge Gentle solids discharge without particle destruction Excellent washing and extraction effect Simple centrifuge design Reliable system for removal of the filter bag Rugged and simple system for the detachable border ring

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BOLZ PROCESS TECHNOLOGY GMBH

Germany

Gypsum Design - Series V 800 - 1600 BG Through many years of experience with renowned plant manufacturers in the area of flue gas desulphurization (FGD) plants, HEINKEL is in a position to ensure smooth, reliable project handling on schedule. Worldwide plaster from flue gas desulphurisation plants is dewatered in power plants using HEINKEL centrifuges. The broad range of plaster centrifuges with different basket sizes allows for optimum adaptation to changing product properties and throughputs. Special properties for the customer´s benefit: Optimum application for small to medium throughputs High availability Minimum residual moisture Maximum reduction of chloride concentrations through optimised washing process Alternatively stainless steel or rubber coated

Request for a quote

BOLZ PROCESS TECHNOLOGY GMBH

Germany

Chemical Design - Series V 800 - 1600 BC The vertical peeler centrifuges types V 800 BC – V 1600 BC are used for uninterrupted operation with high throughput rates in the chemical and fine chemical industries. As with the horizontal centrifuge series, for the vertical peeler centrifuges a wide selection of baskets with different diameters is available. Special properties for the customer’s benefit: Excellent adaptability to changing products High throughputs Separation through filtration or sedimentation Low residual moisture levels through high spinning factor

Request for a quote

BOLZ PROCESS TECHNOLOGY GMBH

Germany

Pharma Design - Series V 1000 - 1250 BP Vertical peeler centrifuges type V 1000 – 1250 BP in cGMP execution are mainly used in the pharmaceutical industry. The process housing opens and closes automatically, thus enabling the complete inspection of all components in the process area. Cleaning is carried out by means of an effective, fully automated CIP system and it is complete with the flooding of the process enclosure if necessary. The GMP and specification compliant documentation ensures optimum qualification. Special properties for the customer´s benefit: Small footprint cGMP compliant Automatic opening, respectively closing of the process housing Optimised product discharge Automatic CIP cleaning Easy accessibility of all machinery parts in contact with the product

Request for a quote

BOLZ PROCESS TECHNOLOGY GMBH

Germany

Chemical Design - Series H 630 - 2100 C The HEINKEL horizontal peeler centrifuges in chemical design are used for separating medium to large product quantities that can be washed and then spin-dried. The centrifuges are designed for continuous operation with large product throughputs. Special properties for the customer’s benefit: Proven, robust design Versatile options available regarding basket and door design, feed pipes and suspension feeding, residual heel removal concepts as well as various unloading devices Bearing designed as exchangeable unit Optimal adaptation to changing products and product characteristics High throughput capacities because of short cycle times Low residual moistures because of high g-forces High product purities because of effective wash process

Request for a quote

BOLZ PROCESS TECHNOLOGY GMBH

Germany

Pharma Design - Series H 630 - 1600 P The HEINKEL horizontal peeler centrifuges in pharma design are characterized by easy cleaning and inspection avoiding product contamination. Special properties for the customer’s benefit: Swinging open housing for easy inspection Clean room installation possible Hydraulically operated housing locking mechanism by single clamping elements, therefore minimal area for product deposit Fully automatic, validated CIP-process possible Design virtually free of dead spaces, minimized number of screwed connections in the process housing Filtrate outlet at the rear part of the process housing, low dismantling expenses to prepare for the opening of the housing High flexibility at frequent product changes Quick change of the filter element Bearing designed as exchangeable unit

Request for a quote

BOLZ PROCESS TECHNOLOGY GMBH

Germany

Series F1 - F4 The HEINKEL inverting filter centrifuge of the Series F requires minimum installation space and is characterized by an integrated clean room design. It is suited for use with diffcult to filter products and characterized by hermetically closed design and the fully automated, continuous operation. Special properties for the customer’s benefit: Advanced development of the proven inverting filter centrifuge Series HF Larger basket volume as well as higher centrifugal forces in comparison with Series HF Easy installation, especially in clean rooms because of outer smooth surfaces and machine contours Inerting system and all junction boxes accommodated in the machine housing Easy access to machine housing via maintenance doors at three sides

Request for a quote

BOLZ PROCESS TECHNOLOGY GMBH

Germany

Series HF 300.1 - HF 1300.1 Based on its gentle product discharge leaving no residual heel and therefore the possibility of thin cake filtration, the HEINKEL inverting filter centrifuges of the Series HF are ideally suited for use with diffcult to filter products. They are characterized by hermetically closed design and the fully automated, continuous operation. Special properties for the customer’s benefit: Proven, robust design Design matches with requirements in the chemical and pharmaceutical industry Best choice for demanding products Residual heel free product discharge and minimum installations in housing and basket, thus optimal for high potent API products with highest possible product yield Considerable residual moisture reduction in respect to conventional filtration by pressure added centrifugation (PAC) possible

Request for a quote

BOLZ PROCESS TECHNOLOGY GMBH

Germany

Chemical Design - Series V 300 - 500 TC The HEINKEL Pilot Plant Vertical centrifuges are characterized by a mobile compact design and easy installation for use in the laboratory and pilot plant. The centrifuge is specially designed for cGMP requirements in the chemical industry. Special properties for the benefit of the customer: Mobile, compact design Very simple installation “plug and use” application Ideal for “upscaling” Jacketed to heat up and cool down Baskets for basic tests for filtration, sedimentation and classifying

Request for a quote

BOLZ PROCESS TECHNOLOGY GMBH

Germany

Pharma design - Series V 300 - 500 TP The HEINKEL Pilot Plant Vertical centrifuges are characterized by a mobile compact design and easy installation for use in the laboratory and pilot plant. The centrifuge is specially designed for cGMP requirements in the pharmaceutical industry. Special properties for the benefit of the customer: Mobile, compact design Very simple installation “plug and use” application Ideal for “up scaling” Very simple to operate CIP cleaning For installation within isolators/glove boxes

Request for a quote

BOLZ PROCESS TECHNOLOGY GMBH

Germany

Chemical Design - Series H 500 - 630 C The wide selection of HEINKEL Pilot Plant centrifuge types with their different basket diameters allows for a solution to the separation task in every application. These machines can be flexibly operated in small production plants because of their design. HEINKEL fulfills the requirements for manufacturing quality, acceptance and documentation for chemical plants. Special properties for the benefit of the customer: Compact design Optional design as tabletop Very simple installation “plug and use” application Ideal for “upscaling” Fully automatic operation

Request for a quote

BOLZ PROCESS TECHNOLOGY GMBH

Germany

Pharma Design - Series H 300 - 500 P The wide selection of HEINKEL Pilot Plant centrifuge types with their different basket diameters allows for a solution to the separation task in every application. Due to their design, these machines can be flexibly operated in small production plants. HEINKEL meets the strict requirements about production quality, acceptance and documentation for pharmaceutical companies. Special properties for the benefit of the customer: Compact design Very simple installation “plug and use” application cGMP compliant Fully automatic operation Ideal for “up scaling”

Request for a quote

SCHMITT-KREISELPUMPEN GMBH & CO. KG

Germany

The U-Do Pump Series is a universally applicable all-rounder. The design and manufacturing materials allow for optimized adaptability for the many different operating conditions as well as for the various media to be pumped. Materials: PVDF (polyvinylidene fluoride) max. output rate: 500 l/min max. discharge head: 40 m motor power: 0.18 - 5.5 kW Advantages: » available with single- or double mechanical seal » applicable also for media to be pumped that do not have any lubricating properties (e.g. varnishes and paints) » the highest chemical resistance » robust, thick-walled design » long-lasting and wear resistant, various types of designs for almost all operating conditions » open impeller (i.e. solids up to 3 mm grain size and 10 Vol. % possible) » easy to maintain (wear parts and the mechanical seal can be changed swiftly) » universally applicable, quiet and compact » various chemical resistant materials can be supplied as stock items

Request for a quoteResults for

Centrifugation - Import exportNumber of results

31 ProductsCompany type