- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- beams

Results for

Beams - Import export

ASSFALG GMBH

Germany

The Assfalg Battery Electro-Permanent Lifting Magnetic Beam EPMBL has a compact design. Due to the integrated rechargeable battery box, a power connection is no longer required. The EPM Battery Magnetic Lifting Beam is operated by remote control. The load lifting beam with a max. load of 1,500 kg is equipped with magnetic modules and can thus safely move sheet metal formats from a minimum length of 500 mm to a maximum length of 4,000 mm.

Request for a quote

FEINMETALL GMBH

Germany

Adaptable to an enormous range of applications, the ViProbe® is a proven buckling beam technology for more than 25 years, valued above all for its uniquely easy reparability.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

Adaptive optics is a special form of high-performance laser mirrors. Their characteristic is that the mirror surface is designed as a membrane, which can be deformed in a controlled manner by pressure change on its back. The shape errors occurring in this case are extremely low; we tolerate them with a maximum of 0.0005 mm. Our adaptive optics are suitable for use with laser power up to 10 KW thanks to integrated direct water cooling and HR coating. Most common types are the adaptive optics with elliptical membrane as these can be used directly to the 90 ° deflection. They are identical to our standard planes of identical aperture and therefore do not need special housings. In addition to the elliptical varieties, LT Ultra also offers round adaptive mirrors. As a rule, these replace the concave spherical mirror of an existing telescopic beam expander directly at the resonator. Round adaptive mirrors can only be used with deflections <10 °. …

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

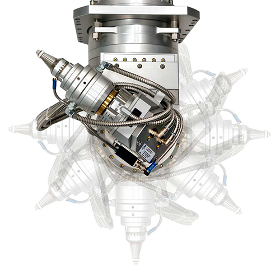

RSLD is our short cut for a laser head consisting of a total of 3 motorized axes for use in large-format laser machines in gantry design for the 3-dimensional laser cutting of components. The horizontal main axis of the laser head permits endless movement, even during the rotary movement the axes below are permanently supplied with cooling water, process gases and all electrical signals. Suitable optics are used for the laser source used, either directly water-cooled metal mirrors with low-absorption coating or alternatively glass optics. The use of an adaptive optics enables the freely programmable focus position for cutting and piercing. The exclusive use of torque motors reduces mechanically moving components and thus guarantees consistently high machining accuracy and best machining results over a long service life, against mechanical damage reliably protects our proven 3D collision protection.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

RSD is our short name for a laser head consisting of a total of 2 motorized axes for use in large-format laser machines in gantry design for 3-dimensional laser cutting / laser welding of components. The horizontal main axis of the laser head permits endless movement, even during the rotary movement the axes below are permanently supplied with cooling water, process gases and all electrical signals. Suitable optics are used for the laser source used, either directly water-cooled metal mirrors with coatings of least absorption, or alternatively glass optics. The use of an adaptive optics optionally allows the freely programmable focus position for cutting and piercing. The exclusive use of torque motors reduces mechanically moving components and thus guarantees consistently high machining accuracy and best machining results over a long service life, against mechanical damage reliably protects our proven 3D collision protection.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

SD is our short cut for a laser head consisting of either the swivel axis only or in combination with a highly dynamic linear axis for laser processing of pipes. Suitable optics are used for the laser source used, either directly water-cooled metal mirrors with coatings of least absorption, or alternatively glass optics. The use of an adaptive optics optionally allows the freely programmable focus position for cutting and piercing. The exclusive use of torque motors reduces mechanically moving components and thus guarantees consistently high machining accuracy and best machining results over a long service life, against mechanical damage reliably protects our proven 3D collision protection. The clear aperture of the current laser swivel head SH35 is 35mm, the larger version SH60 is still available with a clear aperture of 60mm.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

When using high-performance CO2 lasers for welding applications, metal mirrors are usually preferred for beam guidance. Depending on the desired application, the configuration of the machining head is composed of modular individual components according to customer requirements. The possibilities are almost unlimited, ranging from the simplest welding head to complex 3D machining heads. The FH40/C focusing heads are used for laser power up to 5 KW and raw beam diameters up to max. 30mm, the FH60 focusing head for laser power up to 15 KW and raw beam diameters up to max. 50mm. All optical units have connections for direct water cooling, are available with different coatings and are generally available from stock. In addition to the cross-jet for the efficient reduction of splashes and smell on the mirror optics, protective gas feeds with a lateral or coaxial flow direction are also offered for targeted coverage of the welding torch.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

The laser cutting head FC4 is predominantly used in medium power lasers machines, impresses with its slim design and the related low weight. The use of a deformable (adaptive) mirror is of great importance in this case, since no motorized lens adjustment for focus adjustment is required any more. The focus adjustment via adaptive optics above the focusing lens is fast, reliable and precise. Focus positions for a wide variety of materials can be determined, stored in the machine CNC and called up for controlling the optics as desired. The dynamics of the adaptive optics are also clear when piercing the material before the beginning of the cut – for a full stroke, only 0.2 seconds are required. Especially when cutting thicker materials, the time saving can be considerable. The use of aspheric lenses guarantees the best optical properties; protective glass cassettes on both the collimation side and the pressure seal below the focusing lens protect the optics from contamination.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

The laser cutting head FC1 is predominantly used in low to medium power lasers machines, impresses with its slim design and the related low weight. The use of aspheric lenses guarantees the best optical properties; protective glass cassettes on both the collimation side and the pressure seal below the focusing lens protect the optics from contamination. The technical design of the manual adjustment of the focus position is convincing by precision, the focus position can be precisely adjusted without tools via the generously dimensioned adjustment range of 20mm and can safely hold it without countering. The fast distance sensor allows precise control even when cutting the thinnest materials. Thus the FC1 offers excellent cutting performance at an interesting price.

Request for a quote

SCHWEIZER GMBH & CO. KG

Germany

Balance beam for pedal boxes to adjust the braking ratio between the front and rear brakes

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The measuring element of the load cell consists of a double bending beam on which strain gages are applied. The applied force detunes the measuring bridge so that a proportional output voltage is generated. The strain gages on the measuring element are protected against dirt and water spray by a rubber bellows. The sensor can be easily mounted via two mounting holes. The tension or compression force to be measured is introduced at the opposite end perpendicular to the sensor axis. Due to its special design, the influence by an extension (e.g. touch finger) on the measuring signal is low. Overload protection can be realized with little effort using a mechanical stop. FEATURES For tension and compression forces Measuring ranges from 0 ... 5 N to 0 ... 2 kN Relative non-linearity: ≤ ±0.1 % F.S. Very low mounting height Simple force application Material aluminium or stainless steel Special design on request burster TEDS optionally available

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The sensor element consists of a double bending beam with applied strain gages. Changes in the ohmic resistance of the strain gage fullbridge caused by applied forces are converted into electrical voltages. The precise value (characteristic value) of the output voltage, resulting from the application of a rated force to the sensor, is specified in the accompanying calibration protocol. The sensor has to be mounted by two screws on the cable side. The opposite side is meant to receive applied forces (loads). Once the rated stress or strain is exceeded by 20 %, further deflection of the bending beam is prevented by an integrated, mechanical stop. This protects the sensor element against permanent deformation.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The measuring element of this load cell consists of a double bending beam with strain gauges, the resistance of which changes with the application of force. Upon applying a voltage to the strain gauge bridge, the change in the strain gauge resistance is converted into output voltage, which is directly proportional to the force. The strain gauges and the entire measuring element are protected from water spray by metal cover including sealing material. The tensile or compressive load to be measured is applied to the sensor element through the M6 threaded hole located on each end face. The load can be applied easily, along the sensor axis. This serves to prevent falsification of the measured values. Overload protection can be realized with little effort using a mechanical stop. FEATURES Measuring ranges from 0 … 20 N to 0 … 880 N Relative non-linearity: ±0.25 % F.S. Many load cycles Protection class IP54 Excellent price-performance ratio burster TEDS optionally available

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

Full power in any position The universal machines from BEHRINGER can handle any job that is needed. Perfect to slicing through sectional steel as well as solids in metal and comparable plastics at almost any optional angle. With precise cuts, individually adjustable for bidirectional mitre cuts between 90° and 45°, and optionally even for acute angles of 30°. Semi-automatic variants In the BEHRINGER semi-automatic models, the material is positioned by eye, for instance with the aid of a linelaser. This procedure is recommended for frequently changing cut-off length and when the sections are marked on the material already. Automation Where larger cut-off lengths are required, we recommend the use of a measurement device for precise positioning of the material. Used in conjunction with infeed and outfeed peripheral devices such as roller conveyors and transverse transport devices, the degree of automation can be increased to achieve added streamlining effects.

Request for a quote

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

FX-KT small trusses lift workpieces that cannot be picked up with a magnet in the center, such as rings, punching tools and flanges. Two FX magnets, adjustably mounted on a truss made of high-strength aluminum, provide a secure hold. With a few simple steps, the magnets can be removed from the truss and used individually.

Request for a quote

RATEC GMBH

Germany

RATEC magnetic strips for the quick and clean formation of chamfers, drip moulds or dummy joints. Our strips are made of high quality steel (some encased in rubber) with built-in magnets. This means that screwing or welding on the table or on the formwork can be omitted.

Request for a quote

RATEC GMBH

Germany

In addition to the various possibilities of using robots, we also offer different lifting beams for demoulding and easy handling, both for use with RATEC shuttering within and outside the centre of gravity. Our lifting beams are tailored to our shuttering by means of intelligent attachment solutions, allowing for safe and straightforward handling in the plant.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

RATEC GMBH

Germany

Simple and versatile – a wide variety of shuttering tasks can be easily accomplished with the MST. Thanks to its low weight, the MST is very easy to handle without a crane. The system's excellent static properties and fl exibility make the MST a true all-rounder for manual operation.

Request for a quote

ASSFALG GMBH

Germany

The Battery Telescopic Magnetic Traverse EPMBL-T with automatic telescopic arm is a fully battery operated magnetic lifting beam. It enables the mains-independent lifting and transporting of different sheet metal formats (up to 12 t) from 4 mm thickness.

Request for a quoteResults for

Beams - Import exportNumber of results

20 ProductsCompany type