- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- magnetic plates

Results for

Magnetic plates - Import export

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

Plate-spreading-magnets are used for separating of stacked iron and steel sheets. The sheet separators are laterally grown from the sheet stack, they magnetize the sheets with the same poles, which repel them from each other. Plate-spreading-magnets apply both in automated systems where plates with vacuum or transshipped are magnetic, and the manual work, where the gripping sheet is greatly facilitated by their help. Our Plate-spreading-magnets consist of a reinforced magnet system, which is installed in a stable sheet steel housing.

Request for a quote

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

NMS Precision Sine Tables with built PMNM chipboard impress with very good workmanship and precision. The sine table base is hardened to 60 HRC, burnished and precision ground. The angle is adjusted according the sine principle by using gauge blocks. Our NMS sine tables are used in the EDM, grinding and measuring in the highest precision. Technical Details: — Precision Sine Table with built fine pole chipboard — Holding power 100N/cm2 — Magnetic field height 5mm — Pole plate wearing limit 5mm — plane parallelism 0,005/100mm — Angular accuracy +-0.0013°/+-5sec.

Request for a quote

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

The MCF control units are designed to operate electro-permanent magnet modules. It is available both as a single board for installation in the customer's existing control cabinets and as an IP 54 control cabinet solution. In addition to the FXE lifting magnet modules, other electro-permanent magnet components such as magnet clamping plates or magnet clamping blocks can also be controlled with the MCF, both as a single system (ALNICO) and as a double system (ALNICO/ND). The MCF can be controlled via a machine control, radio remote control, manual pushbutton or other potential-free contacts.

Request for a quote

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

FX-WP lifting magnets are waterproof to 1.5m diving depth. The multi-sealed, super-strong permanent magnet system sits in a fully nickel-plated magnet body. It is a diver. FX lifting magnets in universal design convince by their wide field of application. The FX achieves good results with large air gaps as well as with thin flat and round materials with a compact design and low dead weight. The device is characterized by great robustness and a very good price/performance ratio.

Request for a quote

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

Permanent magnetic chucks type PMNEO are super strong, compact plates for heavy cutting. Parts from about 30x15x6mm can be stretched with max. achievable holding forces. Good holding forces can be achieved even on rough surfaces. Optional pole blocks can be built on the PMNEO. This allows turning up the workpiece so that all sides are freely accessible, can be drilled on the magnetic clamping plate and leaves more space for accumulating chips around the component. This allows long-running HSC milling-pieces never sink into the resulting chips. The chipboard is activated via a removable hex shifter. The PMNEO magnetic clamping plate, in 48mm height, is prepared to integrate reference elements directly into the magnetic chuck, so that no additional spectrum is required underneath the magnet.

Request for a quote

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

FXL magnetic clamping blocks are available in many sizes and designs. They can be manufactured with one or more clamping surfaces and different pole sizes. As with the FXL magnetic clamping plates, they are controlled by an FXL-C control unit; optionally with only one channel or also with several channels in order to be able to control the individual clamping surfaces of a block separately.

Request for a quote

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

Permanent magnetic chucks type PMNEO-X are super strong compact chucks for heavy cutting. Parts from about 30x15x6mm are stretched with max. achievable holding forces. Good holding forces can be achieved even on rough surfaces. The chipboard is activated via a removable hex shifter. Structure: — Double neodymium magnet system, steel body — transverse pole pitch 11+4mm — Holding power 150 N / cm2 — Magnetic field height 10mm — Pole plate wearing limit 6mm Recommendation: Super Strong chuck for milling

Request for a quote

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

Permanent Magnetic Circular Chuck Type RNF with neodymium magnet system and low height are used for clamping of small and thin workpieces. Structure: — Neodymium magnet system, steel body, — Max Pole pitch 1,5+0,5mm — Holding power 80N/cm² — Magnetic field height 4mm — Pole plate wearing limit 4mm — Switch travel MAG-ENT-MAG 180° Recommendation: Fine pole circular chuck for small parts

Request for a quote

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

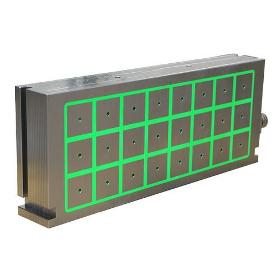

FXL Magnetic Clamping TechnologyThe FXL square pole technology is the result of over 20 years of experience in magnetic clamping technology and combines solutions to the most common customer requirements in the highest quality design. Magnetic poles, fed by Alnico and NDFeB magnets, are anchored in a solid, super-stiff monobloc body by means of a tool steel insert with M8 internal thread. The back of the clamping plate remains flat and can be drilled in at all points - for example, for inserting a zero-point clamping system. For this purpose, the magnet system is coated with highperformance resin in a multi-stage process, which has a high mechanical strength and ensures absolute tightness and perfect electrical insulation. FXL magnetic clamping plates can be controlled with our FXL-C control units or with almost all control units from other leading manufacturers.

Request for a quote

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

Permanent magnetic chucks type PMNM are high precision plates for clamping small and thin parts for precision grinding and eroding. The low magnetic field height prevents magnetization of the processing tools. The chipboard is activated via a removable hex shifter. Structure: — Neodymium magnet system, steel body — transverse pole pitch 1.4 + 0.5mm — Holding power 100 N/cm2 — Magnetic field height 5mm — Pole plate wearing limit 6mm Recommendation: High-precision chuck for grinding and eroding

Request for a quote

ANDREAS MAIER GMBH & CO. KG (AMF)

Germany

Magnetic clamping technology from AMF: safe, reliable and efficient. This innovative technology is based on the force of the magnetic field. This opens up new possibilities that make all surfaces fully accessible for the machining of a workpiece even at constant tension.

Request for a quote

ASSFALG GMBH

Germany

These highly accurate Magnet Sinetables are used for grinding work as well as for eroding. It allows for universal clamping of small, medium and large workpieces of any thickness, however, they are best suitable for thin and fine workpieces. The permanent Microsine magnetic clamping plate is preferably used if a flat and light construction is needed during grinding, eroding or milling. A complete, fine transverse pole distribution (steel/brass) guarantees a consistent holding force over the entire width up to the longitudinal sides. This clamping plate can be activated through a hexagonal switch lever. They are available in two versions: either single-pivotable via the longitudinal axis or double-pivotable via the longitudinal and transverse axis. Gauge blocks can be used to set the tilt angle precisely up to 45 °. The magnet Sinetable is suitable for accurate grinding of workpieces with nonparallel surfaces. Individual designs can be created on request.

Request for a quote

ASSFALG GMBH

Germany

The electronic reverse polarity controllers are used to turn the magnetic clamping plates on and off and to regulate the holding force in several stages through the affiliated manual operating device. With the D50 controllers, up to 100 poles with the pole size 50x50mm or 50 poles with the pole size 75x75mm can be switched. Furthermore, the D100 controller is needed. The single-channel devices D50 and D100 are used to control Magnaslot and Doublemag. The D50-2 controller is needed to operate the Triplemag magnet modules with additional holding surface. If multiple magnetic clamping plates are controlled individually, the D100-4 controller must be used. Up to 4 clamping plates can be switched separately here. Individual requests can be implemented upon customer request.

Request for a quote

ASSFALG GMBH

Germany

The EPFlux magnetic clamping plate has no remanence (residual magnetism) upon deactivation. Highly alloyed and hardened workpieces can be easily loosened from the magnetic clamping plate. Highest grinding precision is achieved, because the plate is not heated up. Not heated up means that there are no expansion and deformation to the workpieces to be processed. The electropermanent magnetic clamping plate is the ideal clamping plate for precision grinding machines. The laminated surface made of brass and steel and the solid steel body guarantee magnetic holding force as well as unique hardness over the entire surface. With the EPFlux magnetic clamping plate, large and small workpieces can be evenly clamped. The magnetizing and demagnetizing occurs through a short power pulse within seconds.

Request for a quote

ASSFALG GMBH

Germany

The patented EPM magnetic clamping plates *** Patent-No. EP1874504 *** have a solid steel surface and are therefore significantly more resistant than conventional plates with epoxy resin against hot chips, coolant and other processing influences. The workpiece is clamped on the EPM magnetic clamping plate MAGNASLOT within seconds through an impulse current. This combo plate allows for 5-side processing of your workpieces in only one clamp. This reduces equipping times to a minimum and increases productivity. Conventional machine vices or clamping claws can be used to clamp non-ferrous workpieces. Through the use of pole extensions, which adjust to the workpiece surface, any unevenness on the workpiece can be compensated for and a deformation of the workpiece can be prevented. The magnet field from the MAGNASLOT magnetic clamping plate guarantees low-vibration clamping of your workpieces.

Request for a quote

ASSFALG GMBH

Germany

The patented EPM magnetic clamping plates *** Patent-No. EP1874504 *** have a solid steel surface and are therefore significantly more resistant than conventional plates with epoxy resin against hot chips, coolant and other processing influences. The workpiece is clamped on the EPM magnetic clamping plate MAGNASLOT within seconds through an impulse current. This magnetic clamping plate allows for 5-side processing of your workpieces in only one clamp. This reduces equipping times to a minimum and increases productivity. Through the use of pole extensions, which adjust to the workpiece surface, any unevenness on the workpiece can be compensated for and a deformation of the workpiece can be prevented. The magnet field from the MAGNASLOT magnetic clamping plate guarantees low-vibration clamping of your workpieces. This protects the milling spindle as well as your tools, increases process safety and extends the service life.

Request for a quote

ASSFALG GMBH

Germany

This highly accurate magnetic clamping plate is used for grinding work as well as for eroding. It allows for universal clamping of small, medium and large workpieces of any thickness, however, they are best suitable for thin and fine workpieces. The permanent Microfine magnetic clamping plate is preferably used if a flat and light construction is needed during grinding, eroding or milling. A complete, fine transverse pole distribution (steel/brass) guarantees a consistent holding force over the entire width up to the longitudinal sides. This clamping plate can be activated through a hexagonal switch lever.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ASSFALG GMBH

Germany

These permanent magnetic clamping plates Permamax from ASSFALG are suitable for heavy clamp-lifting processing. These Permamax permanent magnetic clamping plates can be used for milling, drilling, grinding and slicing. Considerable holding forces are still achieved on uneven and rough surfaces. They allow for universal clamping of small, medium and large workpieces of any thickness, however, they are best suitable for thick and large workpieces. A complete, wide transverse pole distribution (steel/brass) guarantees consistently high holding force over the entire width up to the longitudinal sides. These clamping plates can be activated through a hexagonal switch lever.

Request for a quote

ASSFALG GMBH

Germany

Pole extensions are the perfect complement to the square pole magnetic clamping plates and modules. Workpieces with any structure can be perfectly clamped with Assfalg pole extensions. The pole extensions adjust optimally to the shape of the workpiece. The workpiece is underpinned and is located safely on the extensions,, for a five-side complete processing free of vibration and warping. The surface of the magnetic clamping plate is additionally protected against accidental damage through, for example, deep drilling. Another possible application is use as a stop for 3D forms, round material and smaller workpieces. Other pole extension or pole placement plates are available on request. The connection cables are available in different lengths. They connect the magnetic modules with each other in a row. The controller is additionally connected with the magnetic module through this. The cables are protected against hot chips and cooling water.

Request for a quoteResults for

Magnetic plates - Import exportNumber of results

20 ProductsCompany type