- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machines for installations

Results for

Machines for installations - Import export

KULLEN-KOTI GMBH

Germany

Our brushing machine type BM 1138 has been constructed previously for heavy-duty conveyor belt cleaning in coal mines and foundries. Today we supply it for almost all kinds of industry where conveyor belts have to be cleaned. BM1138-characteristics The particular criteria are: - rugged machine core in welded construction. - high cleaning performance. - minimum belt wear. - small assembly dimensions. - easy retrofitting. - simple mounting to all carrier systems. - integrated vertical adjustment of roller brush. - exchange of the brush coils without removing the roller brush. The brushing machine can be installed at the converyors according position 1-8.

Request for a quote

BÜRKLE GMBH

Germany

SnowPack® enables you to obtain a -79 °C dry ice tablet weighing 50 or 250 g within a few moments, without complicated technology and without electricity! You can therefore obtain low-cost cooling to very low temperatures at any time you like. SnowPack® is often used in hospitals, universities, schools, institutes, laboratories, in the chemical industry and in materials testing facilities. Examples of use: Lowering the temperature in cooling baths or cold traps, pre-cooling tissue samples, ensuring safe transport or embedding biological substances, freezing blood and tissue samples, studies in chemistry, physics and materials technology, etc. Dry ice is easy to handle, odourless and flavourless. The SnowPack® dry ice machine can be installed on any commercial CO2-bottle with a standpipe (without pressure regulator) (thread W 21.80 x 1/14" according to DIN 477-1 No. 6).

Request for a quote

ZOLLER & FRÖHLICH GMBH

Germany

Technical information Product information Designed specifically for the machines of the AM-/CR-series of Zoller + Fröhlich the crimp force monitoring CK 01 is an integrated component for the automatic monitor of crimping operations and thus ensures high quality crimping products. The crimp force monitoring CK 01 can be directly integrated into the machines from Zoller + Fröhlich or installed externally as a retrofit kit. Special features Precise high-speed, crimp force analysis For wire cross-sections from 0.14mm2 – 6 mm² (AWG 26 – 10) Integrated SPC (Static Process Control) with online option Absolute power measurement in Newton [N] TFT-graphic-colour-display with touchscreen Storing up to 50 different programs and parameters Quality assurance through documentation of each crimp Recognize the following crimp faults Missing strands Improper wire gauge Missing crimp contact Inadequate stripping Improper crimp depth

Request for a quote

MASCHINENFABRIK BERTHOLD HERMLE AG

Germany

Designed for machining cubic parts up to 100 kg in weight, the C12 works in the most diverse applications compactly, precisely and dynamically. The C 12 is more than a match for larger models. Aside from its compact size, the main focus is on HERMLE's core competences precision, durability and dynamics. Designed as a 5-axis machining centre featuring the different spindle speeds and different interfaces, the ideal speed is available for almost every area of application. The C 12 can be equipped with two-piece ore compact spindles. All tool spindles can be replaced quickly and easily in case of failure. Thanks to the respective HERMLE set-ups, the C 12 also meets the ever increasing requirements placed on speed and precision. The C 12 machining centre additionally provides extensive options for more intricate applications.

Request for a quote

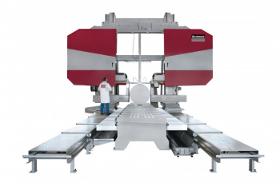

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

In forging mills, rolling and gravity die-casting foundries, and steel finishing works, these machines provide the ideal answer for dealing with large dimensions. They are perfect for preproduction in tool and mold making factories, helping to save valuable milling time. The material support table is recessed in the foundation. Its low-level transition to the hall floor makes for simpler material handling. The moving saw frame can be positioned by axis control precisely at the point of cutting. Where no sawing is taking place, the table is freely accessible. This also allows space for a second piece of material to be loaded while the saw is cutting. This system helps reduce downtime between cuts and enhances productivity. Benefits of the Gantry Machines - Space-saving installation - Durable material support table - Simple positioning of the saw frame - Optional: blade guide with 90° rotation facility for vertical and horizontal sawing to allow notching of materials

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HPM TECHNOLOGIE GMBH

Germany

The brand-new PPJ system impresses not only with its well-conceived components and size but also with its innovative form. In this system, we have combined our decades of experience in an attractive design. The independent regulation of fluid and spray air pressure achieves excellent results even with higher-viscosity media. Available for up to 6 spray heads and in versions with 1, 3 and 5 litres, this system has a very compact design and therefore takes up extremely little space when installed. The system is suitable for the initial equipment of machines as well as for subsequent installation. The PPJ system can be used with our spray heads (starting on p. 20) and the JOP drip-feed dosing device (p. 30) up to a maximum viscosity of 2300 mm²/s at 20 °C or 500 mm²/s at 40 °C (except for substances containing paint, resin and glue).

Request for a quote

FISCHER FORTUNA GMBH

Germany

SFJ high efficiency grinding spindles with oil-mist lubrication. We repair HJN-835 spindles only but we do not deliver this spindle type for new machines any longer. For new installations the HJN-835 is replaced by HJN-828 or HJN-842. Below on this page are listed the available accessories for the HJN828 in the web shop.

Request for a quote

YSTRAL GMBH MASCHINENBAU + PROCESSTECHNIK

Germany

TDS Induction Mixers draw powder, liquids or gases below their level into liquids and at the same time homogenise the contents of the container. The vacuum required for induction is generated in the mixing head. The machine is installed in the container from above by means of a flange or traverse. Alternatively, the TDS Induction Mixer can work on a lifting frame. The powder is inducted from the container and introduced under the fluid level by mixing it immediately and wetting. The mixing head generates the required negative pressure. Dust loads are prevented during the addition of powder by direct induction from the bag. Effective micro and macro mixing of the complete container contents with simultaneous addition of powder. Immediate wetting under fluid level. Complete mass transfer and homogeneity across all container levels via the jetstream mixing principle. In addition, liquids and gases can be inducted.

Request for a quote

ASSFALG GMBH

Germany

The sturdy and easy-to-use chamfering machine was designed for the deburring and chamfering of small to medium-sized workpieces and bar material starting with a thickness of 1 mm. The machine generates a very good chamfering quality thanks to the optimized interaction between the cutter head and cutting inserts. In NE metals and steel, a chamfer width up to 11mm is possible. The WKF 170 has gradual speed regulation, which is very useful when processing aluminum or stainless steel. The angle adjustment can cover a range from 15-60° in 5° steps. For longer workpieces or serial part production, we recommend optimizing the feed unit with pressing pressure, surface quality, feed speed and service life of tools. The machine can be installed on an undercarriage for flexible use in a workshop, which simultaneously serves as a chip box. The machine can be extended with roller guide ways or converted into an automatic chamfering machine.

Request for a quote

ASSFALG GMBH

Germany

The KSM 125 and KSM 130 edge grinding machines are designed for deburring and edge cutting of small to big workpieces starting with a thickness of 2 mm. The chamfer is scrubbed and finished in one step with our two-zone grinding disc. The chamfer setting is made by opening / closing the prism. This is used effectively and efficiently through the axial adjustable corundum grinding disc. The KSM 125 has an integrated extraction socket for connection to an extraction system. A water cooler is installed in the KSM 130. The machines are equipped with hardened and polished guide rails. Hardened workpieces and HSS materials can be processed p to 5mmx45° in multiple steps. For longer workpieces or serial part production, we recommend optimizing the feed unit with pressing pressure, surface quality, feed speed and service life of tools. The machines can be installed on an undercarriage for flexible use in a workshop.

Request for a quote

ASSFALG GMBH

Germany

The sturdy and easy chamfering machine is designed for deburring and chamfering of small to large workpieces from 1 mm thickness. The machine generates a perfect chamfering quality thanks to the optimized interaction between the cutter head and cutting inserts - like sanded. In NE metals and steel, a chamfer width up to 10mm is possible. The ASO160-M is ideal for processing steel and aluminum. The ASO 160-MSL design has speed regulation that is very useful for the processing of aluminum or stainless steel. For longer workpieces or serial part production, we recommend optimizing the feed unit with pressing pressure, surface quality, feed speed and service life of tools. The machine can be installed on an undercarriage for flexible use in a workshop, which simultaneously serves as a chip box.

Request for a quote

ASSFALG GMBH

Germany

The sturdy and easy chamfering machine is designed for deburring and chamfering of small to large workpieces from 2 mm thickness. The sturdy cast iron casing, the hardened and sanded guide rails, the speed regulation and the integrated chip box convince in every regard. Thanks to the optimised interplay of cutter head and cutting inserts, the machine ensures clatter-free, clean and constant chamfering. A chamfer width of up to 10 mm is possible in NE metals and a chamfer width of up to 5mm in steel. Hardened workpieces, HSS and hard metal materials can be processed through optional CBN and diamond grinding discs. For longer workpieces or serial part production, we recommend optimizing the feed unit with pressing pressure, surface quality, feed speed and service life of tools. The machine can be installed on an undercarriage for flexible use in a workshop.

Request for a quoteResults for

Machines for installations - Import exportNumber of results

13 ProductsCompany type