- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machine tool accessories

Results for

Machine tool accessories - Import export

CARL STAHL KROMER - GERMAN MADE SPRING BALANCERS

Germany

Facts: Compact design with a single suspension spring Freely rotating and swivelling screw-type spring hook for suspension Housing and housing cover of high-strength chill-cast aluminum Cable drum of high-strength chill-cast aluminum Closed ball bearings • High-strength special suspension spring • High-strength steel cable • Infinitely adjustable cable stop buffer • Infinitely variable load setting via endless screw Safety: Closed unit Rigid, impact-resistant design Suspension via screw-type spring hook (rotating and swivelling design) Includes safety expansion chain as fall protection Integrated mechanism for locking the cable drum High-strength special suspension spring Spring fracture safeguard is standard Cable overload protection via cable extension limit stop Screw-type spring hook for load suspension GS-certified

Request for a quote

ROCHOLL GMBH

Germany

We can offer a wide range of metal test specimens, starting from different grades of steel in various thicknesses and alloys right through to non-ferrous metals. Are you looking for galvanic finishing or machining solutions? Then you have come to the right place. Punching, deburring, and the rounding of corners are an important part of our portfolio. We will be happy to finish surfaces, for example by means of degreasing or sandblasting. Further finishing options are available upon request. We can also provide test panels with a customized serial number or marking if desired. Stainless steel 1.4301, 1.4571, 1.4401, 1.4310, other grades available upon request Test specimens According to A.F.E.R.A. 4001 (old standard), with defined finish With high-gloss finish (according to FINAT, PSTC standard, A.F.E.R.A. standard 5001, EN 1939) Titanium Grade 1 and grade 5, other grades available upon request Automotive grades painted

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

The MMC 600/900 is the basis for a series of machines that, via several accessories and options, can be fully customized to individual needs. In the basic version the machine consists of a main X-axis featuring a linear air bearing (feed axis), a linear roller bearing Z-axis (infeed axis) and the milling spindle (air bearing) mounted on top of the Z-axis. The main application is face milling of optical and mechanical precision components. Several accessories like a Y-axis, an A-axis and/or C-axis are available, thus expanding the range of machinable parts to microstructures, lenticular structures, spheres, polygons and so on. Accessories, like vacuum chucks, different milling spindles, touch probes for part thickness measurement and even machine interferometers for insitu measurement of workpiece shape, make the MMC 600 and 900 machines an effective tool. Besides further accessories, there is the possibility to make customized solutions, to adapt the machine to your needs.

Request for a quote

KRAMSKI GMBH

Germany

The carbide bushing serves the purpose of preventing tool damage caused by pulled up slug. ADVANTAGES: — Bushings made of carbide — Carbide punches (upon request) — Avoidance of tool damage caused by scrap (pulled up slug), resulting in downtime with corresponding costs — Quality, proven millions of times — Can be produced according to specific customer drawings — Also available without slug retention

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Large workpieces – large chucks – large clamping heads. So far so good, but sometimes you also have to machine smaller workpieces? Instead of buying large clamping heads with a small diameter, there is now a better alternative: the clamping head adapter. For example, it can basically turn a size 100 chuck into a size 65 chuck and you can then change your normal size 65 heads using this clamping head adapter. Your advantages are in-stock availability and a lower price for the smaller clamping heads. You also save the costs of purchasing new large clamping heads if you are already using smaller clamping heads. Changing the clamping head adapter is fast and easy with the suitable changer interface.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Extremely high clamping force Often complete machining fails for lack of an effective I.D. clamping device. In many cases the jaw chuck is a makeshift solution. However, even conventional mandrels with slotted clamping sleeves quickly reach their limits in terms of accuracy, rigidity, and opening stroke. HAINBUCH segmented mandrels use state-of-the-art clamping technology that is convincing, even in the most critical applications. Segmented clamping bushing with extremely hard, wear resistant and rigid segments The central element is the vulcanized segmented clamping bushing. Because conventional clamping bushings are made of spring steel and are only annealed to spring hardness, they are »soft« and they must »bend« to clamp the workpiece. HAINBUCH segmented bushings, on the other hand, are made of case-hardened chromium-nickel-steel and have segments that are extremely hard, wear resistant and rigid.

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Angle head 90° Machining: without spatial constraint Optional: with EC

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

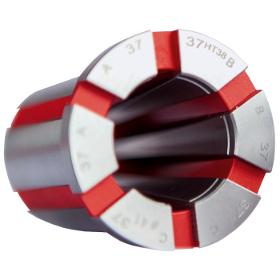

With our hexagonal clamping heads you get up to 25 % more clamping force and higher output with the same clamping cylinder actuating force that is used to actuate our SPANNTOP chucks. The pyramid arrangement of glide surfaces makes it possible. In addition the hexagonal geometry ensures that TOPlus is more resistant to contamination than former clamping head / chuck systems. Therefore, TOPlus is even better suited for raw material, cast and forged parts, as well as fine-particle non-ferrous metals such as brass. With a concentric precision of ≤ 0.005 mm!

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Lower mass The »mini« series really shines with a mass reduced by as much as 30 %, and a chuck diameter that is reduced by 1/3. This means reduced energy consumption and better tool accessibility. Naturally, add on clamping elements can also be used with the TOPlus mini chuck. To maintain the minimal interference contour, the TOPlus mini chuck has its own adaptation devices with a smaller bolt hole circle. Reduced interference contour Thanks to the reduced interference contour, it is easier to choose the tool that you need. Now it can also be shorter and more stable – on the main and sub spindles. Particularly in the case of limited installation space and in series operation, the TOPlus mini chuck is ideal: Lower energy consumption, dynamic spindle acceleration, and shorter cycle times reduce the costs per workpiece. Minimalism that pays off!

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

With our hexagonal clamping heads you get up to 25 % more clamping force and higher output with the same clamping cylinder actuating force that is used to actuate our SPANNTOP chucks. The pyramid arrangement of glide surfaces makes it possible. In addition the hexagonal geometry ensures that TOPlus is more resistant to contamination than former clamping head / chuck systems. Therefore, TOPlus is even better suited for raw material, cast and forged parts, as well as fine-particle non-ferrous metals such as brass. With a concentric precision of ≤ 0.005 mm!

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Reducing operating time and downtime Bring together uniform or diverse processing operations to reduce operating times (usually involves multi-spindle heads). The potential applications are virtually limitless: Drilling, threading, counterboring, reaming, milling, etc. The variety of products is equally diverse, from small compact heads with two spindles to multi-spindle XXL units. BENZ offers interchangeable and fixed-flange (stationary) multi-spindle heads in a wide range of configurations. Multi-spindle heads are typically used for mid-size to large-scale series production. We work in close coordination with you, the customer, to find the perfect solution for your application. Using proven standard components as a basis, we create the optimal multi-spindle solution for you. We maintain close contact with leading machine building companies, giving us the necessary expertise to develop the extraordinary. Give us a challenge!

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Supplement for modular system The morse taper adaptation is a great supplement for the HAINBUCH modular system. Whether face driver, fixed center, a manually activated mandrel, or even tools – with this adaptation you insert anything that you can adapt into the morse taper connection. Extending your chuck within seconds Therefore, you have the possibility of extending your chuck with many additional functions within seconds. This is made possible by the CENTREX quick change-over interface integrated in the adaptation. This means that assembly does not require alignment. Also it is executed with a change-over accuracy of < 0.003 mm at the interface.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Clamp difficult or easily deformable workpieces In daily use you are optimally equipped with the TOPlus or SPANNTOP chucks. However, there are always components that are difficult to clamp due to the contour, or that will be deformed through radial clamping. So what is required is an axial chuck, which in addition can also be set-up very fast. Clamp axially on a neodymium magnet The answer: HAINBUCH magnet module. With the magnet module you can clamp components axially on a neodymium magnet. The HAINBUCH magnet module is set-up in only 30 seconds. Your basic clamping device is already mounted. You exchange the clamping head that is included in the scope of delivery. When clamping, the magnetic clamping device is pulled onto the flat contact area of your basic clamping device.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Depending on size, combined with all adaptations 5-axis machining or rational multiple clamping – with HYDROK we offer a hydraulically actuated stationary chuck that provides even more implementation possibilities. Depending on size – you can use it with all clamping device adaptations, such as the MANDO Adapt mandrel-in-clamping device or with the jaw module. Thus in the future you can also rely completely on the intelligent HAINBUCH modular system, even for your stationary clamping device. Multiple clamping in confined spaces The smallest of the group: HYDROK 40 SE and 32 RD. Their modular base plates can be easily fitted together and enables multiple clamping with incredible holding forces in the most confined spaces. And with an additional tandem cylinder you can even generate the full clamping force with a weaker hydraulic unit.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Reliable and long life SPANNTOP nova – this development represents more than 30 years of SPANNTOP experience. It exploits all the advantages of the latest machine tools. The components are optimized for balance quality, and have an extended guide length. The clamping length of the workpieces is also significantly greater. This chuck is designed for maximum RPM and holding power at ideal concentricity. It is extremely rigid, precise, and has an extremely long life. Convenient change The position-oriented base end-stop of the »combi pull-back« and »combi deadlength« variants can be conveniently changed from the outside via three clamping screws countersunk in the chuck, and for standard chucks, provides excellent accuracy for face location combined with through-bore capacity. Chuck SPANNTOP nova: reliable and solid. The product is the result of more than 30 years of experience!

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

A regular check of clamping force is vital for a safe, precise, and productive process. Do you manufacture at the highest possible metal removal rates? Perhaps your clamping device can do more than you think! Those who face tough competition can no longer afford to manufacture with »theoretical clamping forces«. Nevertheless the DIN EN 1550 requires that static clamping force measurement must be performed by the manufacturer at regular intervals. Modular measuring system The TESTit clamping force gauge measures and records the clamping force for O.D. clamping and I.D. clamping and even the draw-in force of hollow tapered shank locations. TESTit consists of two parts: The basic unit, which is the IT module, and the measuring units, which are the TEST modules. You only need the IT module once – regardless of whether you want to measure the clamping force at O.D. clamping or I.D. clamping or the draw-in force.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

In terms of precision, stability, and flexibility the vulcanized segmented clamping bushings are unbeatable. They consist of segments made of chrome/nickel, case hardened steel that is very hard, extremely wear resistant, and rigid [60 HRC]. Plus, they do not have to »bend« to clamp the workpiece. In addition, all functional surfaces are completely ground in one clamping set-up. The result: maximum run-out accuracy, maximum holding power, and long life span.

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

User friendly, stable and very precise. By combining taper concentricity with no backlash with an extremely large planar surface, combined with high torque, BENZ Solidfix® offers a maximum in stability and rigidity, which is even capable of withstanding the demands of milling. The high torque transmission and the highest possible rpms also stress the effectiveness. This is supported by a special clamping mechanism which works centrally, without lateral forces, which in combination with the compact, highly precise components used achieves optimal values for concentricity, rigidity and accuracy in repeatability. Because of its compact design the system is ideal for tools with internal cooling.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Maximum precision in a mini format The TOPlus premium chuck is ideal for high-precision clamping of delicate and thin-walled parts, as well as solid and massive parts. In combination with premium clamping heads and when clamping against the end-stop, you benefit from incredible run-out accuracy of ≤ 5 μm. That makes the standard TOPlus premium chuck a better and less expensive alternative to hydro-expansion and diaphragm clamping devices. In addition to high precision, the large opening stroke also facilitates automated loading of the machine – even if the robot is somewhat inaccurate. By the way, slight contact with the workpiece during loading has no negative effect on the TOPlus premium. Despite its high precision it remains »robust« and your process remains stable. The most accurate of all HAINBUCH chucks!

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Easy manual actuation The TOROK manual chuck is primarily used in tool prototyping on machines without a clamping cylinder. For example, thanks to its easy manual actuation, when used on grinding machines you can safely and delicately clamp. In combination with our clamping device adaptations, such as the MANDO Adapt mandrel-in-chuck or the jaw module, many more clamping options are possible. Lightweight variant And most recent: Thanks to the optional lightweight CFRP design, with the TOROK CFK you save one-third the weight. This is particularly set-up friendly and it offloads the machine spindle bearings.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

This development represents more than 30 years of SPANNTOP experience. It exploits all the advantages of the latest machine tools. This clamping head is not only extremely powerful, it is also convincing through simple handling. With the changing fixture you set up in no time. The combination of steel and rubber, specially developed by HAINBUCH, in conjunction with a vulcanization that has been perfected over decades, is designed for maximum speed and holding force – with optimal concentricity, and incredible rigidity and service life.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

No problem to change-over from O.D. clamping to I.D. clamping Change-over from O.D. clamping to perfect I.D. clamping, without changing the clamping device? No problem with MANDO Adapt: Place the mandrel in the mounted clamping device, tighten three screws, and lock the mandrel in the clamping device. Reduce time In this process the mandrel engages in the coupling of the clamping device via a sophisticated mechanism, where otherwise the clamping head engages. MANDO Adapt is attractive with extreme rigidity and precision. Without adjusting For rotating products, concentricity of 0.005 mm between chuck taper and mandrel taper can be achieved. For stationary clamping devices repeatability of 0.003 mm is possible. And best of all: This can all be accomplished without adjusting.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Change over from O.D. clamping to jaw clamping or centric clamping in 2 minutes – without clamping device change-over and without having to align ? No problem, with the jaw modules. Because the basic unit, into which the jaw module is inserted, is a HAINBUCH chuck or stationary chuck. If at times the clamping head reaches its limits because it must clamp a larger area, then use one of the jaw modules. The 3-jaw module is best suited for round workpieces, and if you have cubic workpieces, then rely on the 2-jaw module. This means that for a large parts spectrum you are completely flexible and always have the solution that is ideally suited for the respective clamping situation. Both are small, lightweight, and can be quickly changed over – an ingenious solution for small-series production.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Made for the gear-cutting sector Clamping solutions for the gear-cutting sector are individual and have very special requirements. Consequently, it is not easy to find the suitable clamping device, particularly in the case of high variant diversity and smaller lot sizes. The conventional solution is to use fixtures that are more or less effective. Rigid and narrow standard segmented mandrel Fortunately, this is now history. With the MANDO G211 you are relying on a standard segmented mandrel. You profit from in-stock segmented clamping bushings. The rigid and narrow mandrel with optimized tool runout contour is ideal for use in gear cutting applications. Moreover, it can also be used for gear shaping or grinding. Three end-stop levels that are placed with different proximity to the workpiece make it possible to use individual workpiece end-stops. Also a coolant connection ensures process reliability.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Unequalled rigidity Up to 25 % more clamping force and higher output – with the same clamping cylinder that is used to actuate our SPANNTOP chucks. The pyramid arrangement of glide surfaces makes it possible. The clamping head rests with full-surface contact in the TOPlus chuck body – even with large workpiece tolerances. Insensitive to dirt In addition this geometry ensures that TOPlus is significantly less sensitive to contamination than previous chuck/clamping head solutions, and with a concentric precision of approx. 0.015 mm [for chuck size 65]! Thus TOPlus is even better suited for raw material, cast and forged parts, as well as fi ne-particle non-ferrous metals such as brass. Therefore, all-round optimized values make the chuck an ideal partner for modern manufacturing strategies and state-of-the-art machine tools. TOPlus – simply revolutionary!

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Extended variant with many more clamping possibilities MANOK plus, the extended variant of our manual MANOK stationary chuck differs through use of adaptation elements. For example, many more clamping possibilities are available to you in combination with the MANDO Adapt mandrel-in-chuck or the jaw module for even larger clamping diameters. Lightweight variant And most recent: Due to the optional lightweight CFRP design, with the MANOK plus CFK you can save half of the weight. The lightweights are easy to set-up and particularly well-suited for milling machines and machining centers with small load weights. Plus they protect machine components, which ultimately helps the machine accuracy. When loading manually or with a handling system, often the only possible solution is a lightweight stationary chuck.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

centroteX and mandoteX — ideal for today's high-paced manufacturing environment! It is feasible to equip the HAINBUCH quick change-over systems on all your machines, giving you the advantage of changing clamping devices in a matter of minutes, thus earning money quicker. This is because these set-up devices allow you to manufacture with job orientation. And, thanks to our unique CENTREX technology, you will achieve a repeatability of ≤ 0.003 mm on the interface. However, our high-speed solutions have even more to offer: As you will experience shorter machine downtimes along with reduced processing and throughput times, your quick change-over systems will pay off in no time. Better yet, you will not have to compromise on quality, rigidity or pre- cision. Select the spindle connection and the clamping device that is right for you from our extensive assortment. We can even accommodate you if you are already using clamping devices made by other manufacturers.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Lower mass The »mini« series really shines with a mass reduced by as much as 30 %, and a chuck diameter that is reduced by 1/3. This means reduced energy consumption and better tool accessibility. Naturally, additional adaptation elements may also be used with the SPANNTOP mini. An additional ring enables use of the adaptation devices that are also used with the SPANNTOP nova. Reduced interference contour Thanks to the reduced interference contour, it is easier to choose the tool that you need. Now it can also be shorter and more stable – on the main and sub spindles. Particularly in the case of limited installation space and in series operation, SPANNTOP mini is ideal: Lower energy consumption, dynamic spindle acceleration, and shorter cycle times reduce the costs per workpiece. Minimalism that pays off!

Request for a quoteResults for

Machine tool accessories - Import exportNumber of results

66 ProductsCompany type