- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machine maintenance

Results for

Machine maintenance - Import export

NIDEC GRAESSNER GMBH & CO. KG THE GEAR COMPANY

Germany

Why vibration analysis? Information available regarding lifetime of the gearbox Detection of damages on gearset or bearings, impacts, imbalance Lifetime extension of the gearbox and prevention of sudden gearbox failures Cost savings through prevention of unscheduled machine stops Timely maintenance measures before gearbox failure: change of bearings, gearset and other effected parts, replacement gearbox More Information about SmartCheck

Request for a quote

ADS-TEC INDUSTRIAL IT GMBH

Germany

With the software-based Big-LinX Edge Client any machine can be securely controlled and maintained remotely via a Windows-based HMI. The HMI serves as a remote maintenance access point without the need for additional hardware.

Request for a quote

ADS-TEC INDUSTRIAL IT GMBH

Germany

Big-LinX is an IIoT service & maintenance platform for secure remote maintenance of machines and systems, as well as for Industry 4.0 and IIoT applications. Due to remote maintenance, expensive machine downtimes can be minimised or even prevented thanks to preventive and direct interventions. Prepare machine data graphically in dashboards via the cloud and set up alarms. The alarm function is used to inform previously defined employees about a possible malfunction. Big-LinX offers customers a secure investment in the future, as the portal grows with the customer's needs. Get your company ready for digitalisation.

Request for a quote

ANDRITZ KAISER GMBH

Germany

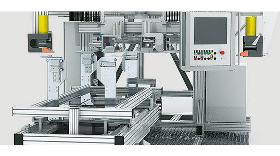

ANDRITZ Kaiser is among the most experienced suppliers of presses and automation for sheet metal forming on the market. High precision, long lifetime of machine and tool, and low maintenance costs speak for the quality of our machines. ANDRITZ Kaiser produces customized solutions for every application – from the stand-alone press or roll feeder to complete production lines with coil handling equipment, finished part handling, scrap handling, and automation system. With over 8,000 automatic punching and metal forming presses worldwide, our customers produce high-quality formed and punched products. Our sheet metal forming solutions find applications in the automotive (OEMs and suppliers), white goods, electronics, electromotor lamination, construction, and consumer goods industries. Numerous well-known companies place their trust in our equipment. Our range of products Complete production lines for blank cutting, electromotor lamination, or conventional stamping Automatic...

Request for a quote

HERBERT WALDMANN GMBH & CO. KG

Germany

MKEL meets the particularly high requirements of the foodstuff industry. The LED integrated machine luminaire is used in packaging machines where it prevents accumulation of dirt and is distinguished by its resistance to agents for sterilising packages or the machine. • Maintenance-free LED technology • Robust aluminium housing with plastic screen • Self-adhesive seal • High degree of protection • Chemically resistant to many media such as cleaning and sterilising agents • Ideal for high thermal stress • Nearly flush-mounted installation • Prevents accumulation of dirt • Direct connection to machine voltage • M12 plug connector

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

EMAG ELDEC INDUCTION GMBH

Germany

eldec brazing systems: automatic induction brazing of pole coils The semi-automatic equipment is designed for manufacturing pole coils of hydro and wind power generators. The machine is based on the experience of the previous manufactured equipments. The machine is designed as a sturdy, high quality and low maintenance machine. The operating is very simple, on automatic mode by 2-hand operation with step by step program and on manual mode by touch-panel.

Request for a quote

OPTIMA NONWOVENS GMBH

Germany

High packaging quality is always the crucial factor. The OPTIMA HS/OS3 bag packer and packaging provides the right packaging to best showcase logos and printing at the point of sales. The adjustable high compression further enhances quality and brings with it a number of advantages in logistics. Optima Nonwovens packaging machines are flexible: The machines can be adjusted quickly and easily for a large range of formats, format sets and modules. Fully automatic high-speed stacker for baby diapers Quick and easy change-over Quality gate Modular machine structure Designed for easy maintenance

BORRIES MARKIER-SYSTEME GMBH

Germany

The workshop unit 322 is a name plate marking unit and is used for very deep markings to mark individual components, prototypes and limited-lot productions. Stable, long life and low-maintenance machine design. Designed for continuous production. Available marking technologies: scribe, stylus, dot marking or DataMatrix marking.

Request for a quoteResults for

Machine maintenance - Import exportNumber of results

9 ProductsCompany type