- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- loading machines

Results for

Loading machines - Import export

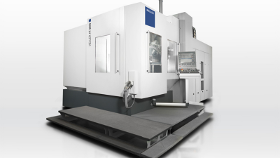

GEBR. HELLER MASCHINENFABRIK GMBH

Germany

5-axis machining centres for powerful complete machining Setting standards in 5-axis: 5-sided and 5-axis simultaneous machining in HELLER quality Highlights Maximum output at optimum quality due to HELLER's extensive process experience Higher availability thanks to adequate speeds and proven HELLER components Innovative spindle technology in three variants providing optimum process stability (swivel head with PCU 63 or SCU 63, fork head with PCT 63) Two control options: Heidenhain iTNC 530 or Siemens Sinumerik 840D sl Advantages Reduced costs thanks to flexible complete machining Optimised life-cycle costs due to innovative manufacturing concept Two machine variants for maximum manufacturing flexibility: workshop machine FT (table loading) for machining of individual parts in tool and die manufacturing and production machine FP (pallet changer) for series production

Request for a quote

ALTMANN GRAPHISCHE MASCHINEN GMBH

Germany

max. size 24 x 20 cm age 2007 banding device max. 25 cycles / min. (off-load) table banding machine electr. foot switch without undercarriage Delivery time: immediately from stock Ref: AF210204A Please ask for price. We ship and install worldwide!

Request for a quote

SCHOCK GROUP

Germany

Cold-drawn heavy-duty rails offer exceptionally high load-bearing capacity and stiffness. In our eShop, you can find partial extensions, full extensions, and over-extensions up to 3000 mm in length and with a load capacity of up to 2400 kg. Cold-drawn heavy-duty telescopic extension rails are suitable for extreme loads and stresses. The precision-machined ball tracks ensure accuracy and provide excellent shock and vibration resistance. Therefore, these telescopic rail models are well-suited for demanding tasks in machinery manufacturing, the military sector, special vehicle construction, and heavy-duty shelving. Due to their extreme strength, these telescopic rails are particularly resistant to lateral forces, making them an excellent choice for dynamic and motorized applications, especially at very large lengths. They can also be used at high temperatures since no plastic parts are used.

Request for a quote

AERO-LIFT VAKUUMTECHNIK GMBH

Germany

Vacuum lifting devices standard are for the horizontal handling of plates. Transportation auf sheet metal, plastic plates, covered wooden plates or glass panes up to 2000 kg. Loading and unloading of machine tools. All AERO-LIFT vacuum lifing devices are build according the actually safety regulations EN13155. Standard lifting device AERO 350-6R Functionality and features Die Vakuumerzeugung der Vakuumheber geschieht durch wartungsarme trockenlaufende Drehschieberpumpen , ölumlaufgeschmierte Vakuumpumpen mit sehr hohem Endvakuum, druckluftbetriebene leistungsstarke Vakuumejektoren beim AERO-LIGHT oder Vakuumgebläse mit Sicherheitsnachlaufschwungmasse bei luftdurchlässigen Transportgütern. Alle AERO-LIFT-Vakuumheber haben eine nach EN13155 vorgeschriebene automatisch...

Request for a quote

HAACON HEBETECHNIK GMBH

Germany

Rack & pinion jack for lifting, lowering, adjusting and fixing of mechanical components, devices, machines etc., load 0,5 t up to 10 t Rack & Pinion Jack, wallmounting 1659 Rack & pinion jack with flange, wallmounting, for pulling and pushing load, capacity 1,5 - 5 t

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Maximum precision in a mini format The TOPlus premium chuck is ideal for high-precision clamping of delicate and thin-walled parts, as well as solid and massive parts. In combination with premium clamping heads and when clamping against the end-stop, you benefit from incredible run-out accuracy of ≤ 5 μm. That makes the standard TOPlus premium chuck a better and less expensive alternative to hydro-expansion and diaphragm clamping devices. In addition to high precision, the large opening stroke also facilitates automated loading of the machine – even if the robot is somewhat inaccurate. By the way, slight contact with the workpiece during loading has no negative effect on the TOPlus premium. Despite its high precision it remains »robust« and your process remains stable. The most accurate of all HAINBUCH chucks!

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Extended variant with many more clamping possibilities MANOK plus, the extended variant of our manual MANOK stationary chuck differs through use of adaptation elements. For example, many more clamping possibilities are available to you in combination with the MANDO Adapt mandrel-in-chuck or the jaw module for even larger clamping diameters. Lightweight variant And most recent: Due to the optional lightweight CFRP design, with the MANOK plus CFK you can save half of the weight. The lightweights are easy to set-up and particularly well-suited for milling machines and machining centers with small load weights. Plus they protect machine components, which ultimately helps the machine accuracy. When loading manually or with a handling system, often the only possible solution is a lightweight stationary chuck.

Request for a quoteResults for

Loading machines - Import exportNumber of results

8 ProductsCompany type