- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- integrated process control

Results for

Integrated process control - Import export

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The RESISTOMAT® model 2329 is particularly suitable for fast measurements of low resistances in automated processes. Up to 50 measurements per second can easily be performed. The device complies with the latest CE guidelines and is designed for laboratory use as well as heavy-duty industrial applications. A 2-fold and 4-fold comparator with switching outputs has been included for classifi cation and selection; this feature is particularly useful for serial tests. One special application involves the measurement of contact resistances (dry-circuit measurement); the load voltage in this case is limited to 20 mV in order to prevent fritting (DIN IEC 512). The RS232 (standard) and IEEE488, USB and Ethernet (option) computer interfaces allow the set-up of fully automatic testing stations. The PLC interface allows easy integration into your production process control.

Request for a quote

ZOLLER & FRÖHLICH GMBH

Germany

Technical information Product information Designed specifically for the machines of the AM-/CR-series of Zoller + Fröhlich the crimp force monitoring CK 01 is an integrated component for the automatic monitor of crimping operations and thus ensures high quality crimping products. The crimp force monitoring CK 01 can be directly integrated into the machines from Zoller + Fröhlich or installed externally as a retrofit kit. Special features Precise high-speed, crimp force analysis For wire cross-sections from 0.14mm2 – 6 mm² (AWG 26 – 10) Integrated SPC (Static Process Control) with online option Absolute power measurement in Newton [N] TFT-graphic-colour-display with touchscreen Storing up to 50 different programs and parameters Quality assurance through documentation of each crimp Recognize the following crimp faults Missing strands Improper wire gauge Missing crimp contact Inadequate stripping Improper crimp depth

Request for a quote

GEMÜ GEBRÜDER MÜLLER APPARATEBAU GMBH & CO. KG

Germany

The GEMÜ 1436 cPos is a digital electro-pneumatic positioner with optionally integrated process controller for the control of pneumatically operated process valves. When using the optional process controller the signals from a process sensor (e.g. flow, level, pressure, temperature) are detected and the media adjusted according to the specified set value. The positioner has a solid housing with protected operating buttons and a LC display. —Digital inputs (option) for variable function control for automation —Fieldbus interfaces e.g. Profibus DP, DeviceNet (option) —No air consumption when idle —Simple mounting to various valve actuators —Access rights via different user levels

Request for a quote

GEMÜ GEBRÜDER MÜLLER APPARATEBAU GMBH & CO. KG

Germany

The GEMÜ 649 2/2-way diaphragm valve has a hollow shaft actuator and is electrically operated. The eSyDrive hollow shaft actuator can be operated as an OPEN/CLOSE actuator or as an actuator with integrated positioner or process controller. An integral optical and electrical position indicator is standard. — Hermetic separation between medium and actuator — Installation for an optimised draining is possible — Open/close function, positioner and process controller — Variable force and speed — Diagnostic functions — Operable via web interface eSy-Web — Electrical and mechanical position indicator — Actuator can be positioned in 45° steps

Request for a quote

GEMÜ GEBRÜDER MÜLLER APPARATEBAU GMBH & CO. KG

Germany

The GEMÜ 539 2/2-way globe valve has a hollow shaft actuator and is electrically operated. The eSyDrive hollow shaft actuator can be operated as an OPEN/CLOSE actuator or as an actuator with integrated positioner or process controller. The valve spindle is sealed by a self-adjusting gland packing providing low maintenance and reliable valve spindle sealing even after a long service life. A wiper ring fitted in front of the gland packing protects the seal against contamination and damage. An integral optical and electrical position indicator is standard. — Linear or modified equal-percentage control characteristics — High flow rates — Force and speed are variably adjustable — Extensive diagnostic facilities — Operable via web interface eSy-Web — Integral optical position indicator and LED high visibility display — Standard gland packing suitable for vacuum up to 20 mbar (abs.)

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

UNITED PROCESS CONTROLS GMBH

Germany

More than SCADA. The Protherm 9800 is a modular production management software for supervising, controlling and archiving heat treating processes and heat treatment installations. It delivers everything to optimize the performance and efficiency of a heat treatment plant operating a variety of furnaces as well as automatic handling machinery. By combining process control, equipment integration, and automation capabilities, the Protherm 9800 provides a comprehensive approach to plant wide supervisory control and management. FEATURES • Highly detailed visualization of all furnaces and connected devices • Scalable set of functions • Module for fully automated production system/cell (lights-out) • Easily implementable interface to existing planning and production systems • Possibility of simulating heat treatments

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The Valve-Tronic Plus™ is designed for use in highly demanding industrial applications that require accurate flow control and measurement. It can function as a stand-alone controller for basic applications or become an integral part of a process control system for automatic flow control. FEATURES • Large LCD displays actual flow rate, totalized flow, valve position, alarms, and diagnostic messages • Field programmable engineering units • Magnetic sensor technology immune to problems related with dirty oil • Configurable to control based on rate of flow or valve position for applications where the Process Variable (PV) is Dew-point, Carbon Potential, etc. • Standard Modbus TCP for easy integration with control systems • Manual actuation of value possible • Field calibration for null and span • Advanced polynomial calibration for high accuracy over the entire range of the meter • Built-in Web Server with remote access to device • Full PID setpoint control The VALVE-TRONIC Plus™...

Request for a quote

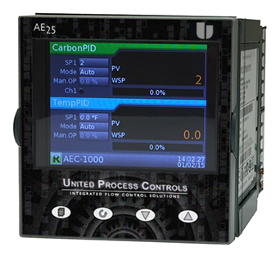

UNITED PROCESS CONTROLS GMBH

Germany

The AE25™ is a ¼ DIN multi-loop process controller provides easy operation and review of process variables and set-point information. FEATURES • controls carbon potential, dewpoint, temperature, and oxygen concentration • paperless chart recorder with USB port for data retrieval • Ethernet (Modbus-TPC) communication port for remote process monitoring and control. • simplified PID tuning with Auto-tune reduces startup configuration time and quickly gets your process up and running fast

Request for a quoteResults for

Integrated process control - Import exportNumber of results

9 ProductsCompany type