- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- industrial heating

Results for

Industrial heating - Import export

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

CONTAINER AND SYSTEM SOLUTIONS FOR THE INTERMEDIATE STORAGE OF HEAT FROM WASTE HEAT OR RENEWABLE ENERGIES The intermediate storage of heat from biogas plants, biomass cogeneration plants or other heat sources is an important prerequisite for effective use. Lipp buffer tank systems are economic system solutions for the storage and supply of thermal energy and can be easily integrated into customised solutions for local heat supply. LIPP BUFFER STORAGE TANKS The individually tailored solution appropriate to heat storage requirements with useful volumes of 80 to 3,000 m³ is made of stainless steel with the Lipp dual seam system and operated in conjunction with insulation adjusted to the application at about 95 ° C. Since the Lipp system is unpressurised, the container solutions are extremely low maintenance and are very durable. The high volume, above ground Lipp storage tanks have been specially developed for this application and are popular with end users and energy suppliers alike.

Request for a quote

ECKARDT SYSTEMS GMBH

Germany

110 Series Our large felt roller lubricators are designed for coil gauges up to 10 mm and viscosities of up to 150 mm 2/sec (recommended guideline values). Fields of application Structural components for the automotive industry: handles, heat shields, oil pans, etc. Fittings for household appliances

Request for a quote

FRIGORTEC GMBH

Germany

With the heat pumps from FrigorTec, the energy of a warm aeration / gas removal or waste water is usually exploited. This is often the case in large kitchens, hospitals or the like. But FrigorTec also offers heat pump series, which come into use in building technology and are used effectively to heat residential or commercial buildings.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The VersaMeter™ is designed to fit direction into a pipeline assembly and can provide either local or remote display options. The VersaMeter™ represents a full range of precision flow measurement instruments and accessories utilizing our proprietary differential pressure flow measurement design proven to meet the rugged requirements of industrial heat-treatment applications. The meters utilize precision, field-proven, and certifiable differential pressure flow measurement sensors. The advanced calibration and display modules on the electronic versions include integrated flow rate alarm and flow consumption totalizing functions. The VersaMeter™ meets current NFPA86 guidelines for safe usage in the thermal processing industry. In addition, every VersaMeter™ comes complete with a 10point calibration curve traceable to a NIST transfer standard. The meters can also be field calibrated to meet CQI-9, ISO, NADCAP and QS quality audit systems. The VersaMeter™ product line comes in...

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The Liquid FurnaceMeter™ is available for liquid flow measurement. These meters are fitted with integrated motorized flow control valves specifically designed for the liquid type, inlet pressures, and scale ranges to provide precision process control for most applications. The Liquid FurnaceMeter™ provides a retrofit foot print to most variable area meters to minimize piping changed when upgrading to differential pressure technology and in-situ calibration capabilities. The Liquid FurnaceMeter™ represents a full range of precision flow measurement instruments utilizing our proprietary differential pressure flow measurement design proven to meet the rugged requirements of industrial heat-treatment applications. The meters utilize precision, field-proven, and certifiable differential pressure flow measurement sensors. The advanced calibration and display modules on the electronic versions include integrated flow rate alarm and flow consumption totalizing functions. The Liquid...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

UNITED PROCESS CONTROLS GMBH

Germany

The VersaMeter™ is designed to fit direction into a pipeline assembly and can provide either local or remote display options. The VersaMeter™ represents a full range of precision flow measurement instruments and accessories utilizing our proprietary differential pressure flow measurement design proven to meet the rugged requirements of industrial heat-treatment applications. The meters utilize precision, field-proven, and certifiable differential pressure flow measurement sensors. The advanced calibration and display modules on the electronic versions include integrated flow rate alarm and flow consumption totalizing functions. The VersaMeter™ meets current NFPA86 guidelines for safe usage in the thermal processing industry. In addition, every VersaMeter™ comes complete with a 10point calibration curve traceable to a NIST transfer standard. The meters can also be field calibrated to meet CQI-9, ISO, NADCAP and QS quality audit systems. The VersaMeter™ product line comes in...

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The FurnaceMeter™ is available for either gas or liquid flow measurement. These meters can also be fitted with integrated manual flow control valves specifically designed for the gas type, inlet pressures, and scale ranges to provide precision process control for most applications. The FurnaceMeter™ provides a retrofit foot print to most variable area meters to minimize piping changed when upgrading to differential pressure technology and in-situ calibration capabilities. The FurnaceMeter™ represents a full range of precision flow measurement instruments utilizing our proprietary differential pressure flow measurement design proven to meet the rugged requirements of industrial heat-treatment applications. The meters utilize precision, field-proven, and certifiable differential pressure flow measurement sensors. The advanced calibration and display modules on the electronic versions include integrated flow rate alarm and flow consumption totalizing functions. The FurnaceMeter™...

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The VersaMeter™ is designed to fit direction into a pipeline assembly and can provide either local or remote display options. The VersaMeter™ represents a full range of precision flow measurement instruments and accessories utilizing our proprietary differential pressure flow measurement design proven to meet the rugged requirements of industrial heat-treatment applications. The meters utilize precision, field-proven, and certifiable differential pressure flow measurement sensors. The VersaMeter™ meets current NFPA86 guidelines for safe usage in the thermal processing industry. In addition, every VersaMeter™ comes complete with a 10point calibration curve traceable to a NIST transfer standard. The meters can also be field calibrated to meet CQI-9, ISO, NADCAP and QS quality audit systems. The VersaMeter™ product line comes in many sizes and is designed to fit directly into equipment piping. The VersaMeter™valve assemblies fit standard pipe fittings to better integrate into...

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The FurnaceMeter™ is available for either gas or liquid flow measurement. These meters can also be fitted with integrated manual flow control valves specifically designed for the gas type, inlet pressures, and scale ranges to provide precision process control for most applications. The FurnaceMeter™ provides a retrofit foot print to most variable area meters to minimize piping changed when upgrading to differential pressure technology and in-situ calibration capabilities. The FurnaceMeter™ represents a full range of precision flow measurement instruments utilizing our proprietary differential pressure flow measurement design proven to meet the rugged requirements of industrial heat-treatment applications. The meters utilize precision, field-proven, and certifiable differential pressure flow measurement sensors. The FurnaceMeter™ meets current NFPA86 guidelines for safe usage in the thermal processing industry. In addition, every FurnaceMeter™ comes complete with a 10point...

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The AccuCarb® Ceramic Probe is a high accuracy zirconia oxygen sensor designed for the heat treating industry. AccuCarb® Ceramic Probe is a patented, ceramic sheathed probe, high temperature probe, specifically designed for generator and for metal sintering applications. The standard model has an integral type K thermocouple and a tube fitting for air purge burnout of soot.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The AccuCarb® Carbon/Oxygen Probe is a high accuracy zirconia oxygen sensor designed for the heat treating industry. This carbon sensing probe is a new, second generation zirconia sensor, specifically designed for highest accuracy, longest life and lowest cost. The AccuCarb® Advanced Probe is specifically designed for thermal toughness and can be installed and removed from a hot furnace in one-quarter of the time of conventional carbon sensors.

Request for a quote

MOSCA GMBH

Germany

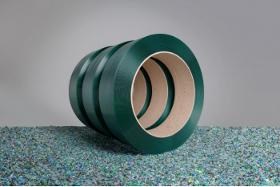

PET strapping is particularly tear-resistant and elastic at the same time. Thus they reliably absorb shocks during transportation and, depending on width, can sustain loads of between 185 and 580 kg. Our PET strapping is available in widths of 9.5 to 15.5 millimeters with tight fabrication tolerances. After use, it can be easily fed back into the material cycle, since it consists of 100 % recyclabled plastic bottles (bottle flakes). It has a high stability for optimal load security. Its constantly high quality ensures a high machine availability. Most frequent fields of application: • Corrugated cardboard industry • Printing industry • General logistics • Electrical industry (TVs, cooling/heating units, kitchen equipment) • Automotive industry (equipment and spare parts for cars, trucks and bikes)

Request for a quote

LIQUOSYSTEMS GMBH

Germany

This cooling unit with heat pump function offers exceptionally high energy efficiency values for both cooling and heating. The device have built-in hydronic module with pump and expansion tank inside. The inverter technology adjusts the compressor speed to the circumstances and enables stable temperatures. Cooling Capacity: • 7°C Coolant – supply flow temperature • 12°C Coolant – return flow temperature • 35°C Outside air temperature of the cooling unit An antifrogen should be used if the flow temperature is below + 10 ° C.

Request for a quoteResults for

Industrial heating - Import exportNumber of results

14 ProductsCompany type