- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- industrial assembly

Results for

Industrial assembly - Import export

PRESSTECK S.P.A.

Germany

For our customers in the automotive and housing industry, we produce deep-drawn stainless steel pots with an integrated axle as a monobloc component. These are used in water pumps for electric vehicles. Our customer from the automotive industry needs pots with an integrated axle that holds a rotor. Up to now, the pot and axle have been joined in a centred manner by means of welding. The customer's wish was to produce a one-piece component to avoid welding. Deep drawing is the ideal technology for this. The size of the component required larger presses than were previously available. Therefore, we first developed tools as prototypes for larger presses on behalf of the customer. After practical tests at the customer's premises as well as at the end customer's, our client decided on a tool that was ideally suited for the production of the component in series.

Request for a quote

FÖHRENBACH GMBH

Germany

Rotary tables with direct drive series RT3 The rotary tables with direct drive are available in different types: RT3A100x100, RT3A100x155, RT3A080x130, RT3A150x100, RT3A150x130, RT3A250x170, RT3A200x060 und RT3G630x225 Rotary tables RT3G630 – high dynamics, high precision, high loading capacity This direct driven rotary table RT3G630 has particularly been developed for machine tool industry and assembly machines. It is characterised by its high precision, highdynamics and its high loading capacity. The rotary table is driven by a permanently excited 3-phase synchronous motor. The rotary plate and the housing are made of gray cast iron.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The incremental digital displays are used in combination with our high-precision displacement sensors 8738. The digital technology of these measuring systems satisfies high demands for precision and long service life, as is required more and more nowadays — in measuring laboratories — in production — in testing laboratories — in workshops and many other areas. Typical uses: —Automatic assembly machines —Semiconductor industry —Keyboard tests —Robot controllers —Testing of shafts and planes —Measurement of differential displacement With its phenomenal resolution of 0.1 µm and the high response frequency of 20 MHz, the 9140 is a powerful display unit with a compact design. The comparator function integrated as standard allows for direct evaluation of measurements almost in real-time; these can be processed further by a higher-level controller. A rather more comprehensive acquisition method is also integrated into the system.

Request for a quote

ETH MESSTECHNIK GMBH

Germany

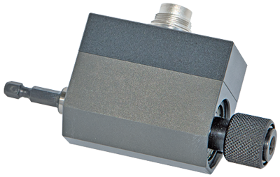

No service needed because of contactless data acquisition High accuracy due to frequency modulation and strain gage technology Single power supply High noise immunity due to amplified active signal integrated sensor-detection chip for use with GMV2 analyzer automotive industry test benches assembly applications pulsed tools hexagonal drive 7 Measurement range from ± 0 - 1 Nm up to ± 0 - 20 Nm optionally with angle measurement

Request for a quote

ETH MESSTECHNIK GMBH

Germany

Particularly suitable for small screwing tools 4 torque range from ± 0 - 0,5 Nm to ± 0 - 5 Nm digital output Square drive or hexagon drive No service needed because of contactless data acquisition High accuracy due to frequency modulation and strain gage technology reduced power consumption High noise immunity due to digital signal very compact design Automotive industry Test benches Assembly applications Pulsed tools

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KROMER GMBH - HERSTELLER UND LIEFERANT FÜR FEDERZÜGE UND BALANCER

Germany

- zero-gravity ability - ergonomic tool support for industrial environements - assembly & production - handling of tools - positioning of tools

Request for a quote

KROMER GMBH - HERSTELLER UND LIEFERANT FÜR FEDERZÜGE UND BALANCER

Germany

- zero-gravity ability - ergonomic tool support for industrial environements - assembly & production - handling of tools - positioning of tools

Request for a quote

KROMER GMBH - HERSTELLER UND LIEFERANT FÜR FEDERZÜGE UND BALANCER

Germany

- zero-gravity ability - ergonomic tool support for industrial environements - assembly & production - handling of tools - positioning of tools

Request for a quote

KROMER GMBH - HERSTELLER UND LIEFERANT FÜR FEDERZÜGE UND BALANCER

Germany

- zero-gravity ability - ergonomic tool support for industrial environements - assembly & production - handling of tools - positioning of tools

Request for a quote

COGNEX CORPORATION

Germany

The In-Sight D900 is a smart camera powered by In-Sight ViDi software designed specifically to run deep learning applications. This embedded solution helps factory automation customers easily solve challenging industrial OCR, assembly verification, and random defect detection applications anywhere on the line that have gone uninspected because they are often too difficult to program with traditional, rule-based machine vision tools. In-Sight ViDi applications are deployed on the In-Sight D900 smart camera without the need for a PC, making deep learning technology accessible to non-programmers. It uses the familiar and easy-to-use In-Sight spreadsheet platform which simplifies application development and factory integration.

Request for a quote

ARNOLD UMFORMTECHNIK GMBH & CO. KG

Germany

Every day, industries throughout the world encounter assembly problems caused by cross-threading. Cross-threading occurs when the screw is misaligned into the female thread. This creates a new thread, which destroys the female thread. Now Arnold UMFORMTECHNIK is able to supply the patented MAThread® dog-point, an innovative solution to this problem. Screws with MAThread® dog points are shorter, lighter and can be used in more applications than other special fasteners. They are easy to fit, and robust, and thus eliminate every problem that commonly occurs with regard to fitting threaded fasteners. The MAThread design allows the designer to select the point shape best-suited to feed well in the application. As the threads come into contact, the patented anti-cross thread MAThread design begins to cam over the female thread. The MAThread design now forces the two thread helixes to align every time without fail.

Request for a quoteResults for

Industrial assembly - Import exportNumber of results

12 ProductsCompany type