- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- handling systems

Results for

Handling systems - Import export

MASCHINENFABRIK BERTHOLD HERMLE AG

Germany

The HS flex family was developed with the goal of "maximum productivity". Ergonomic aspects were completely redesigned, however, to allow for fast and fatigue-free working for operators and service personnel in every possible working situation. The HS flex handling system can be adapted to six different HERMLE machining centers. With a transport weight of up to 450 kg incl. plate and a storage volume of up to 50 plate positions, the HS flex covers a wide range of applications.

Request for a quote

DAMBACH LAGERSYSTEME GMBH & CO KG

Germany

The DAMBACH Vertical Conveyor lifts efficiency to the next level. The free-standing steel construction utilizes warehouse space optimally. The consistent use of poka-yoke techniques and modularcube design allows both fast installation as well as subsequent positioning in confined conditions. Almost any flow of materials can be taken care of with diverse load-handling devices and conveyor elements – two pallets lengthwise or crosswise, a corner transfer module with or without a change of orientation of the conveyed item, and much more. The DAMBACH Vertical Conveyor is one of the highest performing on the market. Each jack can be delivered with preinstallation and decentralized controls. Deepfreeze compatibility up to -28°C comes included at DAMBACH. Compact construction, small lower approach dimensions Inherently stable multiple-column design for heavy loads: up to 3,000 kg Lift speeds up to 240 m/min, lift heights up to 35 m

Request for a quote

DAMBACH LAGERSYSTEME GMBH & CO KG

Germany

The transfer car is based on the innovative DAMBACH Shuttle technology, using power caps for energy storage – making bus bars unnecessary. However, if required a traditional energy supply via bus bar or cable chain is possible. The transfer car can be equipped with up to two load handling devices or with roller or chain conveyors. Good throughput rates Low height Low installation requirements With one or two load-handling units With optional transfer unit for safe transfer of mesh box pallets

Request for a quote

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

Hugo Beck can claim a decade-long development tradition when it comes to automation. We offer support with our expertise throughout the entire automation process, from project planning and manufacture right through to integration into complex packaging lines. Handling systems such as portals, grouping solutions, stacking and counting devices, cross pusher to name but a few, are integrated reliably into the packaging solutions by our technicians. Furthermore, various robots systems are used across many industries for the automated feeding of products, helping to for example grip, position, stack, group, stage products. From a parallel robot (also known as a spider robot) all the way through to a SCARA robot – anything is flexibly possible and delivered fully integrated according to each customer‘s needs. Both robots and handling systems can all be purchased independently of Hugo Beck packaging machines.

Request for a quote

REINHARDT GMBH

Germany

Since decades, Reinhardt ovens “Made in Germany” are working day by day all over the world and are estimated by their reliability and long life time. Adapted to your requirements, a Reinhardt oven delivers the best results that are completely designed to your production process. In the temperature range up to 650° Celsius Reinhardt offers the best solutions for almost all requirements, for heating, tempering, drying, hardening, etc. all designed to your space conditions. All heating technologies, from electrical, direct or indirect gas, oil can be applied. Together with the customer, the Reinhardt industrial ovens are integrated into the production flow. In a classical batch oven, hood oven or pass through oven all thermal processes can be applied with the highest accuracy. Requirements such as lifting doors, charging carrier, transport and handling systems can be easily applied.

Request for a quote

ZIMMER GMBH KUNSTSTOFFTECHNIK

Germany

When it comes to sophisticated plastic injection molding, we are completely in our element. We process all common thermoplastics, from standard to high-performance plastics. A fully automated production with handling systems for part removal and QA tests guarantees an economic production of your parts. We also have experience with the overmolding of various inserts such as threaded bushings, electronic contacts, circuit boards and much more. This and much more are the reasons why we are a reliable partner for almost all industries: Automotive industry aerospace industry Mechanical engineering Medical technology Construction industry Electrical engineering Jewelry and watch industry Furniture industry

Request for a quote

SIKO GMBH

Germany

Magnetic motor feedback systems are proving themselves in numerous applications in linear drive technology, handling systems, circuit board assembly, robotics and in a wide range of automation solutions in the context of Industry 4.0. In all of these areas, the speed and/or position of a drive must be communicated to a main controller in real time. The ultra compact LEC100 and LEC200 sensor duo has been developed by SIKO for these requirements. Repeat accuracy max. ±1 μm. max. resolution 0.2 µm (LD output circuit). Reading distance ≤0.2 mm. Works with MB100/1 magnetic tape. Signal period 1000 μm. Output circuit sin/cos or LD. Function and status display LEDs.

Request for a quote

GUMMIWARENFABRIK EMIL SIMON GMBH & CO. KG

Germany

The complete handling hose system consisting of the hose and connector fittings. The robust multipurpose hose to handle highly abrasive media in all industrial fields. Suitable for a large number of customary fittings or available with built-in SIMON flange. Temperature resistant from –35°C to +80°C. Construction: Highly abrasion-resistant, antistatic tube Tension and pressure-resistant special fabric inlays Optional: Concealed steel spiral Optional: Embedded copper wire UV, ozone and weather-resistant cover Interior smooth, exterior fabric patterned Optional: Exterior corrugated *) Spiral hose version Other versions and dimensions on request.

Request for a quote

METALLUX AG

Germany

We have been developing and manufacturing high-quality industrial thumb, finger and hand joysticks for over 35 years and offer tailor-made solutions for your application.

Request for a quote

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

The FX-HV Horizontal-Vertical System will meet with its diverse setting almost any need. Overall height and focus can be adjusted by plug pins. Likewise, the device also can be used for up to 20% of its rated load without engaging under pads.The support pins are positioned in a way so that standing blanks can be struck, which, for example, is often required on the saw. Likewise lying discs and sheets can be placed. For horizontal transport, the system has a lifting eye on the back. The steel structure is completely coated, and the stable FX Lifting magnet ensures maximum safety. Special dimensions are available on request.

Request for a quote

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

FX-HVS HV systems allow the user to swivel the load suspended on the crane by 90°. By simply locking it to the system, the load can change position from horizontal to vertical at any time. FX HV turning devices make it possible to move horizontal workpieces to the vertical or vice versa. Ask us for more.

Request for a quote

MECHASYS GMBH

Germany

Projects that have already been implemented range from the construction of a "low-cost - high efficiency" laser welding system with CNC axis control focused on customer-specific needs, handling systems, assembly concepts, modular cable shoes, small presses for individual parts (bulk) or continuous goods (stips) for less than 8,000 Euros ... Convince yourself and get back to us! www.mechaSYS.de

Request for a quote

NITTO KOHKI EUROPE GMBH

Germany

Rear exhaust system Vibrationdamping side handle Spindle lock for the replacement of wheel Plastic housing prevents cold hand Side handle can be mounted to right or left Built in governor

Request for a quote

BOLZ PROCESS TECHNOLOGY GMBH

Germany

COMBER Pressofiltro® Series PF 50 - PF 2000 with Containment System Pressofiltro® agitated Nutsche filters or filter dryers with containment system provide protection of the operators against hazardous materials and equally provide product or process safety against possible contamination from external particles. Special properties for the customer’s benefit: Containment systems (glove boxes) are designed to allow contamination free sampling, product discharge, heel removal and product pack-off into suitable containers Containment systems are available as passive, active, single chamber, two chamber and multiple chamber designs, all in compliance with cGMP and FDA guidelines Active isolator units are equipped with air handling systems and HEPA inlet and exhaust filters for containment levels down to 10 ng/m³ TWA The isolator design permits sampling, product discharge, pack-off, heel removal and filter cloth disposal in a single unit Sample and small items transfer using optional...

Request for a quote

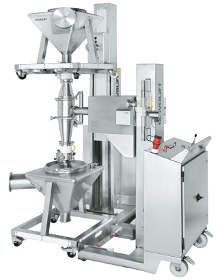

SERVOLIFT GMBH

Germany

Working with and handling drums is done all the time in the pharmaceutical, chemical and food industries. That is why efficient drum handling is a must, and needed in order to optimally structure operational processes. Our products help you with this and offer you a variety of opportunities. Efficient drum handling for drums of any diameter and material Technical description Stainless steel or cGMP-compliant designs High flexibility, such as for drums with any dimensions and of any design No load limitation Tilting function: lengthwise or cross-wise to the column Stationary or mobile designs Floor/ceiling-mounted, free-standing or ceiling-positioned designs Electro-hydraulical or electro-mechanical solutions Extensive series of control designs, from simple direct manual lever controls up to PLC-controlled sequences Various take-up and clamping systems such as a manual clamping ring, motor-driven clamp system, squeeze funnel clamp, fork shaped spears, special designs depending...

Request for a quote

SERVOLIFT GMBH

Germany

A system is only complete when they also fulfill product transfer to interfaces. Thus the specified OEB level is supplied from SERVOLIFT with valves, split valve systems, feed systems, funnels, discharging aids, filling and discharge tubes, etc., corresponding to the containers and handling equipment. The solutions meet the requirements of cGMP and the FDA. Whether protecting the products against their environment, or protecting employees from the product, SERVOLIFT always has the solution, with over 40 years’ experience in the field. Low-dust or dust-free Technical description DECELERATOR: Product transfer from one process to another are often vertical in the pharmaceutical and chemical industry. The feed must then be carried out for the most part over a given vertical distance. Controlled product flow using regulated compressed air transfers the product without segregation at the adapted fall speed in vertical product transfer systems. Segregation-free, controlled product...

Request for a quote

SERVOLIFT GMBH

Germany

These types of machines are used for a variety of applications when combined with process machines. The use of cone mills, hammer mills, vibration sieves, sifters, mobile for various areas or stationary. The broad applications spectrum of these devices can be seen in weighing for raw materials preparation or granulation for calibration, to name two examples. The take-up system is designed and adapted depending upon the process machines and the specified runs. Take-up of various additional devices Technical description cGMP-compliant design Mobile or stationary or combinable for high flexibility Adapted take-up system, depending upon the process machines Variable, adjustable lifting function - for mobile units with telescoping designs for low drive-through heights Function extensions through the integration of tilting and pivoting functions Various containment designs, such as low-dust connections up to high-containment solutions Extensive control designs, depending upon...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SERVOLIFT GMBH

Germany

Lifting, transporting and tilting drums and bins is a typical task especially in the chemical and pharmaceutical industrie as well as in food manufacture. SERVOLIFT, the original handling system, has been manufactured for approximately 30 years. It provides decisive advantages thanks to its two arms: unhindered view of the transport materials, exact and safe operation, uncompromising compliance with all hygiene requirements as well as a higher degree of reliability and cost effectiveness. Strong, maneuverable and easy to operate: the new SL 250 Technical description Free view of the carried load Loads up to 350 kg Explosion protection for zones 1/21 and 2/22 Lift up to 4,250 mm GMP-compliant construction, easy to clean and completely manufactured of stainless steel Faster and easier exchange of the gripper system for various drum types Space-saving due to its very compact design Very maneuverable in confined spaces Can be used everywhere due to its low weight Extendable versions...

Request for a quote

SERVOLIFT GMBH

Germany

Bin lifters from SERVOLIFT are adapted to your bin types. Its modular construction provides for functional extensions by combining special installed components and process machines. One can develop an optimal, ergonomic system solution when using the bin lifters in combination with Servolift containers. Universal handling of all bin types Technical description Stainless steel - or cGMP-compliant designs High flexibility, such as for containers of any dimension and design High load range Stationary or mobile design Floor/ceiling-installed, free-standing or ceiling-positioned designs Electro-hydraulical or electro-mechanical solutions Wide range of control designs, from simple, direct manual lever controls up to PLC-controlled sequences Integration of product controls, such as installation of dosing units Pick up of containers, including discharge aid and valve actuators Extensive take-up and clamp systems, container holding device, fork shaped spears, special designs depending...

Request for a quote

SERVOLIFT GMBH

Germany

Storage, production and operating levels are often linked in a vertical fashion for smooth material flow. A SERVOLIFTt platform lifter is a sensible solution to an elevator. Space-saving, and able to execute the platform with various accesses helps to solve space problems in material flow. A closed hoistway is not needed. Platform lifters for simple material or passengers transport, mobile or stationary. Technical description Access to the platform in the lower floor: Additional ramps Ramp to the carrying arm Trench under the carrying arm for even loading Platform with even surfaces as a transport footprint including a railing with a single door Column behind the access point Column lateral to the access point 2 access points Application: Installation in hoistway (as a material elevator) Lifting containers (such as drums, bags) to feed a system Lifting liquid containers for gravimetric emptying

Request for a quote

SERVOLIFT GMBH

Germany

The broad applications spectrum of SERVOLIFT milling and sieving equipment leads to flexible and user-friendly solutions in combination with handling systems. The areas of application stretch from controlled sieving in order to remove contamination from raw materials to fractionation, calibration to deagglomeration. Sieve mills, vibration sieve machines or inline sieve equipment in combination with mobile or stationary lifting systems provide a flexible, compact and easy-to-clean system. Size as needed Technical description Stainless steel or cGMP/FDA compliant designs Use as sieve mills (cone mills), hammer mills, oscillating sieve mills Various throughput depending upon the product and particle size Lifting height can be customized Broad control designs, from simple microcontrollers with digital displays to PLC controls Explosion-protected designs in adherence to Atex Zone 1/21 and 2/22.

Request for a quote

ANDREAS MAIER GMBH & CO. KG (AMF)

Germany

Wireless seonsoring systems from AMF: flexible, compact and economical. They enable fully automated production processes for clamping technology as well as for modern handling and storage systems. The system consists of sensors and transmitter units that are interlinked both with the gateway and recipient, which communicates wirelessly with the machine control by means of Bluetooth Low Energy.

Request for a quote

DAMBACH LAGERSYSTEME GMBH & CO KG

Germany

DAMBACH roller conveyors consist of a stable frame with rollers bolted in place. The rollers are driven by an easily serviced tangential chain drive with tensioning unit housed in a drive enclosure. The entire drivetrain is enclosed for safety and to prevent tampering. Flanged wheels rotate with the rollers to help transport goods carefully. The frame is height-adjustable. DAMBACH chain conveyors consist of self-supporting chain strands mounted on a rigid frame. The number of strands can be varied to suit the application. Duplex chains with straight side plates guarantee careful transport of your goods on an optimised support surface. Chains are supported on low-friction slide rails and can be individually tensioned. All chain strands are driven via a common driveshaft fully enclosed for safety. The mounting frames bolted to the main frames are height-adjustable. High throughput rates Travelling speed up to 0.5 m/s and acceleration up to 0.8 m/s² Max. 1500 kg per storage position

Request for a quote

DAMBACH LAGERSYSTEME GMBH & CO KG

Germany

DAMBACH lift tables are efficient transfer units for mergers, crossings or branches in flows of materials. Roller or chain conveyors can be integrated as required. The interlocking lift mechanism combined with a rigid frame protects the unit loads and ensures optimum availability. As an option, variable intermediate lift positions can be included to ensure greater flexibility. The compact dimensions and safety guards expand the range of applications. Turntable with Roller or Chain Conveyor Turntables can divide or merge flows of materials without changing the orientation of the unit loads. The highly dynamic turntable drives from DAMBACH are interlocking units and ensure precise rotational angles of up to 270° with any number of intermediate stops. For optimum occupational safety, our turntables can be fully enclosed. In addition, the innovative modular design guarantees numerous and diverse applications and ease of servicing at the same time.

Request for a quote

MÜLLER GMBH

Germany

Small handling equipment - Müller AGILO FDA and GMP compliant Suitable for cleanroom service Hygienic and easy to clean Everything in stainless steel ISO 9001 quality management No maintenance Customized versions also possible AGILO P pallet truck 110 mm lift 90 mm fork height when lowered 520 mm entry width Fork length 1140 mm Fork width 160 mm Weight 80 kg Load capacity 2300 kg Rollers in non-marking polyurethane or polyamide FDA-tested low-temperature oil Also available for ATEX Zones 1, 2, 21, 22 AGILO S scissor lift truck Lifting height up to 1090 mm 90 mm fork height when lowered 540mm entry width Fork length 1480 mm Fork width 178 mm Weight 165 kg Load capacity 1000 kg Rollers in non-marking polyurethane or polyamide FDA-tested low-temperature oil AGILO H mini lifter Lifting heights up to 1750 mm (floor to pickup centerline) Width 1100 mm Height 1982 mm Reach 810 mm Weight approx. 300 kg Load capacity 150 kg Rollers in non-marking polyurethane of polyamide Suitable for...

Request for a quote

MÜLLER GMBH

Germany

Container handling & container lifting Robust and reliable stationary container handling systems are required where high weights have to be managed effectively. In pharmaceutical production, in particular, Müller's well-thought out container lifters are an integral part for the greatest variety of process tasks. We develop mobile and stationary designs to meet your requirements. The stationary container handling systems are equipped with robust forks and a weighing unit, if required. Container lifter with grinder lift column Type FTHSK 1000 G5-2 lifting weight 1000 kg height 6 m Design: lifting, inverting, swivelling, grinding - all motorized Container Wash Station high pressure, 150 bar warm-cold water rotating injection nozzle validation possible Container lifter for rectangular containers lift and swivel column Type FTHS 1000 G4 loads up to 1000 kg column height 5.0 m Design: motorized lift manual swivel Emptying and charge weighing Emptying and charge weighing system for..

Request for a quote

MÜLLER GMBH

Germany

Müllers pallet transfer systems and units are available in several types for different applications. Among others we offer automatic feeders for conveying, transfer systems with gate for a process flow in both directions, transfer units with adjustable side walls or fixed side walls. with fixed side walls Standard pallet transfer unit Type PW 800 Loads up to 1000 kg Design: for wooden and aluminum pallets; fixed side walls with motorized adjustable side walls Standard pallet transfer unit Type PW 800 Loads up to 1000 kg Design: for wooden and aluminum pallets motorized side walls with manually adjustable side walls Standard pallet transfer unit Type PW 800 Loads up to 1000 kg Design: for wooden and aluminum pallets manually adjustable side walls with gate for flow in both directions Standard pallet transfer unit Type PW 1000 D2 Loads up to 1000 kg Design: for wooden one-way and aluminum pallets motorized side and end walls automatic sequence Automatic feeder for conveying...

Request for a quote

MÜLLER GMBH

Germany

Müller drum and container blenders - almost like plug and play. Blender or blending column, drum or container – bulk solids such as granules or powders are mixed reliably by an intelligent system; which if required can provide a data report for tracking blender settings such as weight, mixing times and number of revolutions. You therefore have complete documentation for your quality assurance system. Müller drum and container blenders are adaptable for your processes: Gentle action Highly effective Safe Blending parameters can be set With data report Blending column with weighing facility Container tumbler FTHMW 1500 MG8 Lifting weight 1500 kg Height 6 m Design: tumbling and weighing - fully automatic emptying Container Blender Lift / swivel / tumble column Type FTHMS 600 MG7 Loads up to 600 kg Column height 4.0 m Design: motorized lift, swivel, grip and tumble actions Stationary blender for drums Tumbling stand Type FTMh 300 MG1 Loads up to 350 kg Height of unit 1.6...

Request for a quote

MÜLLER GMBH

Germany

All our drum lifters do not only handle your drums safely, they also meet GMP-standards. All lifting, inverting and swiveling columns work with electric motors which is very low noise level and operator friendly. For all different types of drums we can offer drum lifters with suitable pick up systems. The slim but stable mast offers the operator a safe visibility to the load. You can manage all handling operations like feeding of tablet presses, capsule filling machines, blister packaging machines, sieves or other transferring tasks with a Müller drum lifter. The lifting operation is always done by electric motor, all other operations like clamping, inverting and swiveling can be done either manually or by electric motors. Drum lifters from Müller are known for economic, save and ergonomic drum handling. Drum lifters with universal clamp lift / swivel / invert column Type FTHSK 300 G2 loads up to 300 kg column height 3.6 m Design: motorized lift manual grip, invert and swivel...

Request for a quoteResults for

Handling systems - Import exportNumber of results

33 ProductsCompany type

Category

- Goods handling systems, continuous (4)

- Storage equipment and systems (4)

- Magnets (2)

- Automatic payment and cash handling systems (1)

- Automation - systems and equipment (1)

- Mechanical engineering - custom work (1)

- Grinding - machine tools (1)

- Heat treatment furnaces (1)

- Joints, pneumatic (1)

- Machine tools - metal machining (1)

- Machine tools, metal machining - parts and accessories (1)

- Management training (1)

- Sealing and wrapping - machinery and equipment (1)

- Sensors (1)