- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- extreme products

Results for

Extreme products - Import export

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The model 8527 high-precision compression load cell is the ideal load cell for reference measurement chains where highly precise measurement results are required. Its very high production quality and extremely low non-linearity of just 0.035 % F.S. make it a dependable choice for comparative measurements and calibration tasks. Designed for a dynamic stress of up to 100 % of the full scale value, the model 8527 load cell is also suitable for situations where a rapid signal change with high amplitude occurs and has to be measured. The model 8527 high-precision compression load cell has a domed load button on top, onto which the compressive load being measured is applied. Inside the load cell is an elastic membrane, on which strain gages generate a resistance change in the measuring bridge and an output signal proportional to the load. For the best possible measurement results, the force should be applied axially and centrically to the load button.

Request for a quote

FLÖTER VERPACKUNGS-SERVICE GMBH

Germany

Different film types can be processed on our efficient AirBoy nano4, giving you the best flexibility for your goods dispatch even with low throughput. AirBoy nano4 Fastest small machine on the market 4 speed modes 4 / 6 / 8 / 10 m per min No heat-up phase - air cushions can be produced immediately Easy exchange of transport belts Production of extremely tight air cushions possible without compressor Ideal for small packing stations for air cushion production on demand Start/stop at the touch of a button Variable timer for air cushion production Variable sealing temperature, air volume Compatible with narrow air cushion chains Compatible with wide air cushion mats Supplied with instructions, power cord, 2 spare PTFE bands and spare blade Different types of films and cushion types can be produced on our low-cost AirBoy nano3. Therefore you have the best flexibility for your transport protection, even with low throughput.

Request for a quote

FLÖTER VERPACKUNGS-SERVICE GMBH

Germany

Different film types can be processed on our efficient AirBoy nano4, giving you the best flexibility for your goods dispatch even with low throughput. AirBoy nano4 Fastest small machine on the market 4 speed modes 4 / 6 / 8 / 10 m per min No heat-up phase - air cushions can be produced immediately Easy exchange of transport belts Production of extremely tight air cushions possible without compressor Ideal for small packing stations for air cushion production on demand Start/stop at the touch of a button Variable timer for air cushion production Variable sealing temperature, air volume Compatible with narrow air cushion chains Compatible with wide air cushion mats Supplied with instructions, power cord, 2 spare PTFE bands and spare blade Content of the nano4 Standard starter set: AirBoy nano4 air cushion machine 1 roll air cushion chain | Type 9.7.

Request for a quote

FLÖTER VERPACKUNGS-SERVICE GMBH

Germany

Different film types can be processed on our efficient AirBoy nano4, giving you the best flexibility for your goods dispatch even with low throughput. AirBoy nano4 Fastest small machine on the market 4 speed modes 4 / 6 / 8 / 10 m per min No heat-up phase - air cushions can be produced immediately Easy exchange of transport belts Production of extremely tight air cushions possible without compressor Ideal for small packing stations for air cushion production on demand Start/stop at the touch of a button Variable timer for air cushion production Variable sealing temperature, air volume Compatible with narrow air cushion chains Compatible with wide air cushion mats Supplied with instructions, power cord, 2 spare PTFE bands and spare blade Content of the nano4 paper bio starter set: AirBoy nano4 air cushion machine 1 roll air cushion chain | Type 9.7.

Request for a quote

FLÖTER VERPACKUNGS-SERVICE GMBH

Germany

Different film types can be processed on our efficient AirBoy nano4, giving you the best flexibility for your goods dispatch even with low throughput. AirBoy nano4 Fastest small machine on the market 4 speed modes 4 / 6 / 8 / 10 m per min No heat-up phase - air cushions can be produced immediately Easy exchange of transport belts Production of extremely tight air cushions possible without compressor Ideal for small packing stations for air cushion production on demand Start/stop at the touch of a button Variable timer for air cushion production Variable sealing temperature, air volume Compatible with narrow air cushion chains Compatible with wide air cushion mats Supplied with instructions, power cord, 2 spare PTFE bands and spare blade Content of the nano4 bio starter set: AirBoy nano4 air cushion machine 1 roll air cushion chain | Type 9.7.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

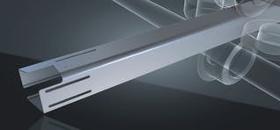

SCHOCK GROUP

Germany

SCHOCK is your specialist in the production of cold-rolled profiles tailored to individual customer requirements. With a wide range of different technologies, we manufacture special profiles as customized functional elements up to complete assemblies. SCHOCK's roll forming technology operates economically and material-efficiently, offering significant advantages in product design: Unlimited range of shapes Highly precise functional dimensions Economical material utilization Energy-efficient manufacturing process SCHOCK special profiles are characterized by the highest precision and top-notch workmanship. With SCHOCK's roll forming technology, we produce profiles with extremely tight tolerances and excellent product properties. Thanks to creative tool solutions, we manufacture virtually burr-free profiles and process different materials with a tensile strength of up to 1000 MPa.

Request for a quote

HERMA GMBH

Germany

452C - the high-flyer in top labeling: Equipped with the HERMA 500. Precise top labeling on all types of surfaces. Easy to integrate into any kind of production line. Extremely efficient and highly productive. Space-saving, compact and hugely versatile. Easy to integrate printers for variable labeling. Can be combined with the highly reliable 552C bottom labeler.

Request for a quote

HERMA GMBH

Germany

Two-in-one labeling solution: A variety of optional modules for any labeling task. Equipped with the HERMA 500. Top and bottom labeling in one cycle. Easy to integrate into any kind of production line. Extremely efficient and highly productive. Space-saving, compact and hugely versatile. Also suitable for top or bottom labeling only.

Request for a quote

HERMA GMBH

Germany

Get your labeling off to a flying start with the 552C: Equipped with the HERMA 500. Precise bottom labeling for the undersides of products. Easy to integrate into any kind of production line. Extremely efficient and highly productive. Space-saving, compact and versatile. Easy to integrate printers for variable labeling. Can be combined with the highly reliable 452C top applicator.

Request for a quote

HERMA GMBH

Germany

752C: Looking to seal your products securely? With a machine base constructed of stainless steel, the compact, sturdy and food-grade 752C can operate in practically any production environment where hygiene is a priority. With the integrated HERMA 500, absolutely precise dispensing is guaranteed – even with particularly challenging four-side labeling. C-wrap labeling for top, front & bottom labeling. D-wrap labeling for top, front, bottom & back labeling. C or D-wrap labeling in one single pass. In just a few simple steps and without any tools, it can be adjusted to different product sizes within minutes. Easy to integrate onto any kind of production line. Extremely efficient and highly productive. Space-saving, compact and extremely versatile.

Request for a quote

OPTIMA CONSUMER GMBH

Germany

- Continual self-optimization of all operational parameters with regard to output and precision - Extremely low “give away” (product loss) due to mean value control. Any fluctuations in bulk weights are detected and immediately adjusted - Wide filling range without need for format change - Few moving parts, thus little wear and low maintenance costs - Stored formula parameters can be called off at any time for rapid product and weight conversion - Smooth surface for easy cleaning - Graphical user interface providing clear presentation of all important production and status data - Innovative weighing technology - Safe and robust mechanical engineering - The most modern control and drive components - Touch-screen operating unit

OPTIMA CONSUMER GMBH

Germany

- Extremely low “give away” (product loss) due to mean value control - Any fluctuations in bulk weights are detected and immediately adjusted - Wide filling range without need for format change - Stored formula parameters can be called off at any time for quick product or weight changeover - Automatic zero point correction - Graphical user interface providing clear presentation of all important production and status data - Innovative weighing technology - Safe and robust mechanics - Modern system control

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Maximum machining capacity MAXXOS T211 is a mandrel with a hexagonal pyramid shape instead of a round taper – perfect for demanding and reliable process manufacturing. Through the hexagonal clamping pyramid, maximum transmission forces can be realized. The segmented clamping bushing with the hexagon socket sits on the clamping pyramid with an absolute positive fit, which enables maximum machining capacity with less vibration and thereby less tool wear. The lubrication, combined with its leak-tightness ensures an extremely constant production flow and therefore maximum reliability. By the way, our segmented clamping bushings offer a factory-standard run-out accuracy of ≤ 10 μm. If you need even greater precision, there are two additional levels of run-out quality to choose from. Even a run-out accuracy of ≤ 2 μm is possible upon request.

Request for a quoteResults for

Extreme products - Import exportNumber of results

14 ProductsCompany type