- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- container storage

Results for

Container storage - Import export

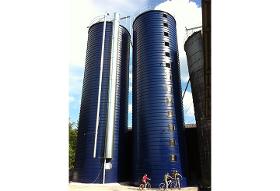

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

MADE FROM VERINOX STAINLESS STEEL OR GALVANISED STEEL WITH VOLUMES RANGING FROM 40 M3 TO 10,000 M3 Both industry and communities require professional solutions for plant and tank construction and for the storage and treatment of liquids, as well as flexibility in terms of size, choice of material and equipment. When constructing liquid storage tanks, the selection of the best material is an important quality factor. Municipal/industrial waste water and sludge or certain processing, intermediate and end products from the chemical, pharmaceutical and food processing industries set high requirements regarding the tank material, for example. LIPP offers a variety of materials, ranging from galvanised steel through the combination material Verinox to high alloy stainless steels. APPLICATIONS Waste water tanks Sewage sludge tanks Process water tanks Storage tanks Firefighting water tanks Mixing and compensation tanks Buffer Tanks Stackable sludge tanks Storage containers

Request for a quote

ECKARDT SYSTEMS GMBH

Germany

Dosing system VB 10: the sound entry-level solution The VB 10 dosing system operates without any pressure. It hangs above the roller lubricator; the oil is supplied to the machine purely through the force of gravity. The capacity of the VB 10 storage container is 10 litres.

Request for a quote

ECKARDT SYSTEMS GMBH

Germany

Dosing systems The right amount every time Compact & efficient Our supply and dosing systems are designed to harmonize perfectly with all Eckardt lubricators. These range from small integrated dosing devices through to standalone oil supply solutions with filter units and tank heaters. Features & benefits • Individual dosing and storing solutions • Integrated tank heater and filter units optional • Suitable for oils of all manufacturers and viscosities • Available in all sizes and performance data Design versions and details Dosing system VB 10: the sound entry-level solution The VB 10 dosing system operates without any pressure. It hangs above the roller lubricator; the oil is supplied to the machine purely through the force of gravity. The capacity of the VB 10 storage container is 10 litres. Dosing system DB 10: lubrication made easy The dosing system DB 10 uses a pressure vessel with a capacity of 10 litres. This is equipped with a filler ball valve and plastic funnel, a p

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

Efficient on site production enables silos with a variable diameter to be installed quickly and cost effectively at the customer’s site. ACCESSORIES Modules prefabricated at the factory, e.g. filling and draining systems, can be installed and added. THOUSANDS OF PROJECTS REALISED WORLDWIDE The tried and tested LIPP system has been used to construct thousands of systems all over the world for more than 55 years. In particular, customers value the longevity of the tank solutions and the possibility of easily modifying them or fitting a wide variety of accessories during their service life. A selection of the projects carried out using LIPP bulk storage containers is shown below

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FLÖTER VERPACKUNGS-SERVICE GMBH

Germany

AirWave - Rolling basket ECO (made of canvas, without sensor) for AirWave 1/2 The universal air cushion rolling basket is mobile and always brings your air cushions to the ergonomically correct working height. Our storage containers are ideal for the production of air cushion filler and wrapper with a width of up to 50cm. 4 rollers (2 lockable), material: stainless steel, colour: beige dimensions of the bag: 80 x 50 x 55 cm / capacity: approx. 220 litres.

Request for a quote

ERNST WAGNER GMBH & CO. KG

Germany

Hygiene waste bin with integrated storage container at the top for standard paper sanitary bags in stainless steel (AISI 304) for surface mounting. Allstainless steel housing; all corners fully welded, visible surfaces satin finished and brushed. Equipped with removable hygiene bin. Capacity approx. 6 l. Accessible through lockable door with selfclosing, flameretardant disposal flap. Keyed alike cylinder lock in corrosionresistant zinc diecasting. Delivery includes fixing material. Dimensions 298 x 448 x 120 mm

Request for a quote

STOROPACK HANS REICHENECKER GMBH

Germany

AIRplus® TRANSFORMS AIR INTO THE OPTIMAL PROTECTIVE PACKAGING. Light as a feather and reliably shock-resistant, Storopack’s AIRplus® air pillows are the optimal protective packaging for sensitive products. A variety of pillow shapes can be produced as required directly at the packing station, therefore saving valuable storage space. All AIRplus® machine types can be integrated into existing packing processes – including in combination with automated packing lines and storage containers at the packing station. The range includes four different film types: Prepackaged products can be ideally blocked and braced in the carton with AIRplus® Void, as the large air pillows optimally fill the void. Smaller and medium-sized AIRplus® Cushion and AIRplus® Bubble air pillows are exceptionally flexible, and can be used to cushion, block, and brace or wrap sensitive products. Thanks to its innovative, diamond-shaped structure, AIRplus® Wrap is the ideal substitute for traditional bubble...

Request for a quote

OPTIMA CONSUMER GMBH

Germany

Containers - Container or cap feed as bulk goods via fully automatic sorting and optional storage bin - Container classification using a rotary feeder - Container transport using pucks for flexible production and fast conversion - Container transport without pucks possible - Cycled container transport - Very gentle processing of the containers - Processing different container shapes Shapes -User-friendly, fast and primarily tool-free format change Design - Simple assembly (plug and play) - low installation costs - Good visibility and accessibility - Compact design with low space requirement - Compact design with integrated control cabinet - Secure and sturdy mechanical system Drive - Drive via wear-free servomotors Manufacture/Closing - Positioning the caps manually for semi-automatic processes - Closing systems coordinated to the product

OPTIMA CONSUMER GMBH

Germany

Containers: - Container or cap feed as bulk goods via fully automatic sorting and optional storage bin - Container classification using a portioning device - Centering the container for the optimal positioning of the containers below the work stations - Cycled container transport Design: - Simple assembly (plug and play) - low installation costs - Explosion protection model is optional - Good visibility and accessibility - Min./max. Sensors for jam detection upstream and downstream of the machine - Secure and sturdy mechanical system - Standard version with 1 working station - Few moving parts resulting in minimized sealing and maintenance costs Drive: - Precise compliance with the torque specification using the slipping clutch or permanent magnet coupling - Screw spindle with adjustable speed Manufacture/Closing: - Simple integration into existing packaging technologies - Processing all standard types of caps

OPTIMA CONSUMER GMBH

Germany

Containers: - Container or cap feed as bulk goods via fully automatic sorting and optional storage bin - Container classification via the infeed screw - Continuous container transport - Optimized container transport for preventing splashing in little headroom - Very gentle processing of the containers and packaging - Processing different container shapes Shapes: - User-friendly, fast and primarily tool-free format change Design: - Can be designed as a monobloc combination with filling and sealing modules - Good visibility and accessibility - Integrated separation for reject product and/or production patterns - Min./max. Sensors for jam detection upstream and downstream of the machine - Secure and sturdy mechanical system Manufacture/Closing: - Processing all standard types of caps

OPTIMA CONSUMER GMBH

Germany

Containers: - Container or cap feed as bulk goods via fully automatic sorting and optional storage bin - Continuous container transport - Optimized container transport for preventing splashing in little headroom - Very gentle processing of the containers and packaging Shapes: - User-friendly, fast and primarily tool-free format change Design: - Simple assembly (plug and play) - low installation costs - Explosion protection model is optional - Good visibility and accessibility -Compact design with low space requirement - Min./max. Sensors for jam detection upstream and downstream of the machine - Secure and sturdy mechanical system - Few moving parts resulting in minimized sealing and maintenance costs Manufacture/Closing: - Simple integration into existing packaging technologies - Processing all standard types of caps

OPTIMA CONSUMER GMBH

Germany

Containers: - Container or cap feed as bulk goods via fully automatic sorting and optional storage bin - Container classification via the infeed screw - Container transport using pucks for flexible production and fast conversion - Continuous container transport -Optimized container transport for preventing splashing in little headroom - Very gentle processing of the containers and packaging - Processing different container shapes Design: - Can be designed as a monobloc combination with filling and sealing modules - Good visibility and accessibility - Integrated separation for reject product and/or production patterns - Compact design with low space requirement - Min./max. Sensors for jam detection upstream and downstream of the machine - Secure and sturdy mechanical system Manufacture/Closing: - Simple integration into existing packaging technologies - Processing all standard types of caps

Results for

Container storage - Import exportNumber of results

14 ProductsCompany type