- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- blanking

Results for

Blanking - Import export

ROCHOLL GMBH

Germany

We produce blanks from plastic in line with your specifications. Upon your request, we also process pellets specified and also provided by you in our injection molding department. We keep a wide range of common plastic grades in stock, which we process into test specimens of various sizes according to your specifications. On request we also procure special materials and process these in line with your specific requirements. We process every available type of pellets to form DIN A5 format sheets or smaller sheets lap shear test specimens 100 x 25 x 3 mm dumbbell test specimens We deliver various surface finishes structured high-gloss automotive graining used by a wide range of car manufacturers We deliver every SMC quality depending on the availability of prepregs with class-A finish also in automotive quality Types of plastics ABS, PC, PE, PMMA, POM, PP, PS, PVC, PET, PTFE, PA6, PA6.6, PU, Polymer-based glass fiber-reinforced plastics

Request for a quote

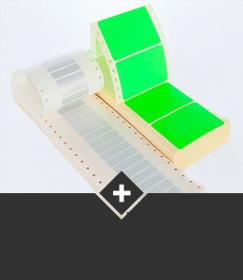

ETIKETTENDRUCK FÖRSTER GMBH & CO.KG

Germany

If you want to keep your internal processes, your production line or the transport of your goods to their destination running smoothly and efficiently, professional aids such as suitable labels are indispensable. With the right labels, you can check the sequence of goods or see the whereabouts and progress of all goods en route to the point of arrival at any time. With special, continuous or variable markings, every product that has ever left your company can be identified again at any time — with the help of professional labels from Förster.

Request for a quote

ANDRITZ KAISER GMBH

Germany

ANDRITZ Kaiser provides complete circular and multi-form blank cutting lines, including feeder, press, stacker, and scrap conveyor. The production of blanks for further use in a deep drawing or embossing process imposes strict demands on the press and automation system. Precise timing and general performance are required in order to achieve competitive productivity. Due to the large amount of cutting required, a very rigid machine is needed to absorb the rebound without damaging any equipment. Finally, the tolerances of the end product call for a very precise slide movement and low frame deformation. ANDRITZ Kaiser can look back on decades of experience in the field of blank cutting lines. Our well-designed and thoroughly tested concept allows our customers to manufacture high-quality products with maximum efficiency. Our production lines for circular or multi-form blanks are characterized by the following aspects: Highly stable machine with split-design cast iron or combined...

Request for a quote

SIMPAC EUROPE GMBH

Germany

C-frame presses are flexible solutions for manual work as well as for automated production processes. The CS is the all-rounder among the C-frame presses, while the ECS is ideal for punching and cutting operations with a higher degree of automation. Overview: ● Press capacity: 350-3,000 kN ● Part size: small ● Slide kincematics: crank ● Application: cutting, stamping, bending, embossing Description and benefits: ● Compact design, no foundation work required, good accessibility for maintenance ● Solid, low-stress annealed press body in monobloc design with minimal frame deflection ● Durable, wear-resistant and very quiet hydraulic clutch ● Casting slide with vibration dampening properties (ECS series) ● 4-fold slide guiding for a high tilting rigidity ● Hydraulic overload protection ● Production time as of 12 weeks

Request for a quote

OPTIMA CONSUMER GMBH

Germany

Containers: - Container classification via the infeed screw - Container transport using pucks for flexible production and fast conversion - Cycled container transport - Continuous container transport - Very gentle processing of the containers and packaging - Processing different container shapes Shapes: - User-friendly, fast and primarily tool-free format change - Fully or semi-automated format change is optional

OPTIMA CONSUMER GMBH

Germany

Containers: - Container classification using a rotary feeder - Container classification via the infeed screw - Container transport using pucks for flexible production and fast conversion - Cycled container transport Shapes: - User-friendly, fast and primarily tool-free format change Design: - Simple assembly (plug and play) - low installation costs - Good visibility and accessibility - Compact design with low space requirement - Compact design with integrated control cabinet - Glue gap or tuck-in gap closure is possible - Modular machine design for maximum flexibility for future adaptations of products, packaging or functions - Few moving parts resulting in minimized sealing and maintenance costs

Do you sell or make similar products?

Sign up to europages and have your products listed

Results for

Blanking - Import exportNumber of results

6 ProductsCompany type