- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- 5-axis machining centre

Results for

5-axis machining centre - Import export

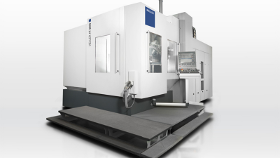

GEBR. HELLER MASCHINENFABRIK GMBH

Germany

5-axis machining centres for powerful complete machining Setting standards in 5-axis: 5-sided and 5-axis simultaneous machining in HELLER quality Highlights Maximum output at optimum quality due to HELLER's extensive process experience Higher availability thanks to adequate speeds and proven HELLER components Innovative spindle technology in three variants providing optimum process stability (swivel head with PCU 63 or SCU 63, fork head with PCT 63) Two control options: Heidenhain iTNC 530 or Siemens Sinumerik 840D sl Advantages Reduced costs thanks to flexible complete machining Optimised life-cycle costs due to innovative manufacturing concept Two machine variants for maximum manufacturing flexibility: workshop machine FT (table loading) for machining of individual parts in tool and die manufacturing and production machine FP (pallet changer) for series production

Request for a quote

GEBR. HELLER MASCHINENFABRIK GMBH

Germany

5-axis machining centres for milling and turning operations HELLER process competence at its best: machine series providing unique cutting performance for milling and turning operations Highlights Combined Processing: milling and turning on a single machine Tool provides 5th axis: 5-axis machining, horizontal, vertical and tilted turning High precision and cutting forces for turning operations due to specific spindle fixation Rotary table with direct torque drive Integrated balancing function Advantages A one-off investment that ensures flexible production today and in the future One machining centre for all machining tasks Two machine variants (CP/pallet changer or CT/table loading) providing maximum flexibility for use Typical HELLER performance for milling and turning operations Reliable productivity thanks to HELLER services

Request for a quote

MASCHINENFABRIK BERTHOLD HERMLE AG

Germany

The C 650 uses a modification of HERMLE's tried-and-tested gantry-type design, with a mineral-cast machine bed. The integrated, rigid clamping table can cope with workpieces up to a maximum of 3000 kg (1050 x 900 x 600 mm) in the 3-axis version, making it ideal for toolmaking, mould construction and machine construction. The swivelling rotary table of the 5-axis version can accommodate workpieces up to 1500 kg (Ø 900 x 600 mm), allowing for highly precise machining. The traverse path in the stainless-steel-clad working area comprises 1050 x 900 x 600 mm with a vertical table clearance of 775 mm and a door aperture of 1050 mm. Ideal parameters for simple and safe crane charging. The C 650 has an integrated tool magazine for 42 tools. The control panel of the C 650 is also designed to swivel easily to the magazine loading location, so the operator can enter the tool data directly into the tool table in the control system.

Request for a quote

MASCHINENFABRIK BERTHOLD HERMLE AG

Germany

Within the HERMLE range of models, the C 250 is an entry-level model into the world of 5-axis & 5-sided machining. Nevertheless, the “large” models are in no way inferior. Thanks to the large swivelling range of the workpieces in the working area, the utilisation of the complete traverse range and the large collision circle between the table side walls, the C 250 offers the largest working area relative to the installation area. The C 250 is designed for daily use – maximum user-friendliness thanks to pivotable control panel and minimum table distance from the operator and optimum loading height with option ofloading by crane. Maximum precision thanks to the HERMLE swivelling rotary table concept. The table variants of the C 250 therefore stand for the highest quality and optimum use of material – from the cast housing to the installed gear motors: Made in Germany – made in Gosheim.

Request for a quote

MASCHINENFABRIK BERTHOLD HERMLE AG

Germany

Designed for machining cubic parts up to 100 kg in weight, the C12 works in the most diverse applications compactly, precisely and dynamically. The C 12 is more than a match for larger models. Aside from its compact size, the main focus is on HERMLE's core competences precision, durability and dynamics. Designed as a 5-axis machining centre featuring the different spindle speeds and different interfaces, the ideal speed is available for almost every area of application. The C 12 can be equipped with two-piece ore compact spindles. All tool spindles can be replaced quickly and easily in case of failure. Thanks to the respective HERMLE set-ups, the C 12 also meets the ever increasing requirements placed on speed and precision. The C 12 machining centre additionally provides extensive options for more intricate applications.

Request for a quote

MASCHINENFABRIK BERTHOLD HERMLE AG

Germany

5-axis/5-sided machining means the C 42 lends itself to be used in every application area. With traverse paths adapted to the workpiece size and perfectly designed for 5-axis applications, the C 42 is ideal wherever complex, close-tolerance components are required. This includes various applications in the tool and mould making, medical, aerospace, motorsport, machine sectors and other industries: The C 42 machining centre is at home in every area. The space-saving circular tool magazine integrated into the base body of the machine works according to the pick-up principle - thus enabling quick tool changes. In the standard version, the C 42 can hold 42 tools and can be extended to 192 pockets. The control panel can be easily adjusted to the respective user. Milling and turning in one clamping with the C 42 U MT dynamic model. Fully integrated rotary table that does not interfere with demanding milling processes and 5 axes simultaneously.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

5-axis machining centre - Import exportNumber of results

6 ProductsCompany type