- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- storage bins

Results for

Storage bins - Import export

ELKON GMBH

Germany

ELKOMIX-120 QUICK MASTER Compact Concrete Batching Plant which is equipped with 3000/2000 l. ELKON twin shaft mixer and 4x20 m³ aggregate storage bin can be transported quickly and economically to anywhere in the world due to its folding and modular designed structure. ELKON Compact Concrete Batching Plants, which reflect ELKON's manufacturing culture based on high technology and experience since 1975, provides the following advantages to its users - Quick and easy installation (only 2 days) - Cost effective sea and land transportation - Possibility of installation on a confined space - Quick and easy relocation - Flexibility in the configuration - Minimum foundation cost (only flat concrete surface is adequate for installation) - Easy maintenance and low operating costs - High production performance with optimized automation system

Request for a quote

ELKON GMBH

Germany

ELKOMIX-60 QUICK MASTER which is equipped with 1500/1000 l. ELKON twin shaft mixer and 4x15 m³ aggregate storage bin can be quickly and economically transported to anywhere in the world by only 2 units 40’ OT container (or by 2 units TIR) thanks to its folding and modular designed structure. ELKON Compact Concrete Batching Plants, which reflect ELKON's manufacturing culture based on high technology and experience since 1975, provides the following advantages to its users - Quick and easy installation (only 1 day) - Cost effective sea and land transportation (2 units 40’OT container or 2 units TIR) - Possibility of Installation on a confined space - Quick and easy relocation - Flexibility in the configuration - Minimum foundation cost (only flat concrete surface is adequate for installation) - Easy maintenance and low operating costs - High production performance with optimized automation system

Request for a quote

DURABLE HUNKE & JOCHHEIM GMBH & CO. KG

Germany

Self-adhesive floor-marking shape “T” for indicating danger zones, storage spaces, walkways etc. • Floor marking shape: "T" • Floor-marking shape for indicating dangerous areas, storage spaces, walkways, etc. • Self-adhesive symbol for application on floors in interior areas • Abrasion resistant and hard-wearing • Colour code: RAL 1003 signal yellow

Request for a quote

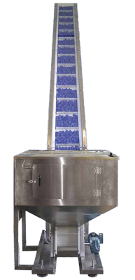

CL MACHINERY GMBH

Germany

Closure Systems International's closure elevator pre-feeders are designed to feed closures to sorters from the ground level. Via a cleated belt, closures are fed from a bulk storage bin at ground level to a sorter mounted on a capping machine. CSI Closure Pre-Feeder Features & Benefits Stainless steel construction Bin sizes available: ✓ 10 cubic feet ✓ 25 cubic feet ✓ 50 cubic feet ✓ 100 cubic feet Can be custom designed to meet any delivery rate Can be custom designed for any closure size and type Clean-out door for quick changeover Lexan bin cover for clear visibility Lexan conveyor cover to keep dust out High and low level photo sensors Self-contained stainless steel control panel Controls can be integrated with capper controls Best to be combined with a rotary sorter and placed next to the capper Markets Served: Beverages, Food, Pharmaceutical, Automotive Fluids, Personal Care, Home Care, and Custom Applications Unmatched Technical Support / Application Expertise!

ERNST WAGNER GMBH & CO. KG

Germany

Hygiene waste bin with integrated storage container at the top for standard paper sanitary bags in stainless steel (AISI 304) for surface mounting. Allstainless steel housing; all corners fully welded, visible surfaces satin finished and brushed. Equipped with removable hygiene bin. Capacity approx. 6 l. Accessible through lockable door with selfclosing, flameretardant disposal flap. Keyed alike cylinder lock in corrosionresistant zinc diecasting. Delivery includes fixing material. Dimensions 298 x 448 x 120 mm

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OPTIMA CONSUMER GMBH

Germany

Containers: - Container or cap feed as bulk goods via fully automatic sorting and optional storage bin - Raising the container when filling to prevent dust accumulation - Container transport using pucks for flexible production and fast conversion - Centering the container for the optimal positioning of the containers below the work stations - Cycled container transport - Optimized container transport for preventing splashing in little headroom - Very gentle processing of the containers and packaging - Processing different container shapes Manufacture/Closing: - Simple integration into existing packaging technologies - Process-reliable sealing using thermal sealing, induction or ultrasound is possible - Processing all standard types of caps - Processing packaging material from the stack

OPTIMA CONSUMER GMBH

Germany

Containers: - Container or cap feed as bulk goods via fully automatic sorting and optional storage bin - Raising the container when filling to prevent dust accumulation - Centering the container for the optimal positioning of the containers below the work stations - Cycled container transport - Very gentle processing of the containers and packaging - Processing different container shapes Manufacture/Closing: - Simple integration into existing packaging technologies - Process-reliable sealing using thermal sealing, induction or ultrasound is possible - Processing all standard types of caps

OPTIMA CONSUMER GMBH

Germany

Containers: - Container or cap feed as bulk goods via fully automatic sorting and optional storage bin - Container classification via the infeed screw - Continuous container transport - Optimized container transport for preventing splashing in little headroom - Very gentle processing of the containers and packaging - Processing different container shapes Shapes: - User-friendly, fast and primarily tool-free format change Design: - Can be designed as a monobloc combination with filling and sealing modules - Good visibility and accessibility - Integrated separation for reject product and/or production patterns - Min./max. Sensors for jam detection upstream and downstream of the machine - Secure and sturdy mechanical system Manufacture/Closing: - Processing all standard types of caps

OPTIMA CONSUMER GMBH

Germany

Containers - Container or cap feed as bulk goods via fully automatic sorting and optional storage bin - Container classification using a rotary feeder - Container transport using pucks for flexible production and fast conversion - Container transport without pucks possible - Cycled container transport - Very gentle processing of the containers - Processing different container shapes Shapes -User-friendly, fast and primarily tool-free format change Design - Simple assembly (plug and play) - low installation costs - Good visibility and accessibility - Compact design with low space requirement - Compact design with integrated control cabinet - Secure and sturdy mechanical system Drive - Drive via wear-free servomotors Manufacture/Closing - Positioning the caps manually for semi-automatic processes - Closing systems coordinated to the product

OPTIMA CONSUMER GMBH

Germany

Containers: - Container or cap feed as bulk goods via fully automatic sorting and optional storage bin - Container classification via the infeed screw - Container transport using pucks for flexible production and fast conversion - Continuous container transport -Optimized container transport for preventing splashing in little headroom - Very gentle processing of the containers and packaging - Processing different container shapes Design: - Can be designed as a monobloc combination with filling and sealing modules - Good visibility and accessibility - Integrated separation for reject product and/or production patterns - Compact design with low space requirement - Min./max. Sensors for jam detection upstream and downstream of the machine - Secure and sturdy mechanical system Manufacture/Closing: - Simple integration into existing packaging technologies - Processing all standard types of caps

OPTIMA CONSUMER GMBH

Germany

Containers: - Container or cap feed as bulk goods via fully automatic sorting and optional storage bin - Container classification using a portioning device - Centering the container for the optimal positioning of the containers below the work stations - Cycled container transport Design: - Simple assembly (plug and play) - low installation costs - Explosion protection model is optional - Good visibility and accessibility - Min./max. Sensors for jam detection upstream and downstream of the machine - Secure and sturdy mechanical system - Standard version with 1 working station - Few moving parts resulting in minimized sealing and maintenance costs Drive: - Precise compliance with the torque specification using the slipping clutch or permanent magnet coupling - Screw spindle with adjustable speed Manufacture/Closing: - Simple integration into existing packaging technologies - Processing all standard types of caps

OPTIMA CONSUMER GMBH

Germany

Containers: - Container or cap feed as bulk goods via fully automatic sorting and optional storage bin - Continuous container transport - Optimized container transport for preventing splashing in little headroom - Very gentle processing of the containers and packaging Shapes: - User-friendly, fast and primarily tool-free format change Design: - Simple assembly (plug and play) - low installation costs - Explosion protection model is optional - Good visibility and accessibility -Compact design with low space requirement - Min./max. Sensors for jam detection upstream and downstream of the machine - Secure and sturdy mechanical system - Few moving parts resulting in minimized sealing and maintenance costs Manufacture/Closing: - Simple integration into existing packaging technologies - Processing all standard types of caps

ALLIT AG KUNSTSTOFFTECHNIK

Germany

Mobile rack for stackable storage bins / Easy-to-assemble stand made of zinc-coated sheet steel / Completely equippable with the provided 226 assorted ProfiPlus Box storage bins / High stability thanks to sturdy fixed and swivel castors / Polyamide rollers: less maintenance work; improved safety thanks to a locking device. / Individual boxes can be loaded with a weight of 2-5 kg. (Box 1/2/2L: max. 2 kg, Box 3/4: max. 5 kg)

Request for a quoteResults for

Storage bins - Import exportNumber of results

14 ProductsCountries

Company type